https://www.youtube.com/watch?v=W_6eSued2ZY

For Andreas, who is always ready to maiden my planes, I designed a Delta.

He gave me the shape, as well as the profiles and dimensions for balsa laser cutting parts.

I liked it so much that I also wanted to create a print version.

However, initial estimates of the weight distribution showed that the required, far forward CG could not be achieved because of the high weight share in the rear. This was only possible with LW PLA. Thus, the weight can be reduced almost to half.

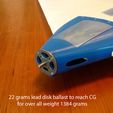

To keep the weight as low as possible, I screwed a 22 gram lead disk on the front as ballast.

But that was not necessary at all. We added 191 grams of ballast so that the plane would not glide so long when landing. This means the Delta can take a total weight of 1575 grams, the flight characteristics are still good.

Because of stability, and also to shift the weight forward, I recommend printing the front part of the fuselage in PLA or PETG. But in any case the wingend, because it should hold the through going 8 mm carbon tube with a screw.

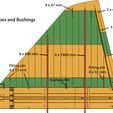

You need several carbon tubes diameter 8mm, 4mm and 3mm as shown in the picture.

The front and rear parts of servo segment, W1 W2 and all elevon parts must be glued together.

Also the fuselage connector into fuselage 2 and fuselage 3 to fuselage 4.

All other parts can be screwed so you can easily exchange parts if necessary.

More informations

https://www.rc-network.de/threads/andreas-delta.11822532/

https://www.rcgroups.com/forums/showthread.php?3754295-Andreas-Delta

Specifications

airfoil: NACA 0006

wing span: 1100 mm

wing chord: 680/200 mm

CoG: 460 mm from rear

overall weight: 1384 g (with 2200mAh 3S battery)

wing area: 48 dm²

wing loading: 28,8 g/dm²

motor: Surpass 3542 1450kV

propeller: Aeronaut CAM Aeronaut Carbon Classic 9.5 x 6"

static thrust: 1300 g (3S Lipo)

battery: Turnigy 2200 mAh 3S

motor camber: tilted -2°

Print settings

All fuselage parts and battery base: layer height =0,2mm, perimeters =3

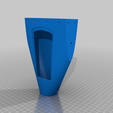

fuselage 1: extrusion width 0.52 mm, 15 bottom layers, 3 top layers, no infill

fuselage 2: extrusion width 0.45 mm, 2 bottom layer, 3 top layer, no infill

fuselage 3: extrusion width 0.45 mm, 2 bottom layer, no top layer, no infill

fuselage 4: extrusion width 0.45 mm, 2 bottom layer, no top layer, 45% infill

connector fuselage: extrusion width 0.45 mm, 2 bottom layer, 4 top layer, no infill

battery base: extrusion width 0.45 mm, 4 bottom layer, 4 top layer, 30% infill

All acces panels/brackets: layer height 0.2 mm, spiral vase mode

acces panel 1: extrusion width 0.5 mm

acces panel 2 and 3: extrusion width 0.45 mm

All acces panel brackets: extrusion width 0.5 mm

hook insert: extrusion width 0.5 mm, layer height 0.25 mm, 1 perimeter, 2 bottom/top layer, no infill

bushing M4: extrusion width 0.4 mm, layer height 0,15 mm, 2 perimeter, no bottom/top layer, no infill

servo segments, W1, W2

layer height 0.25 mm, extrusion width 0.5 mm, 1 perimeter, 4 bottom/top layer, no infill

wing end: layer height 0.2 mm, extrusion width 0.4 mm, 2 perimeter, 4 bottom/top layer, no infill (PLA)

servo mount: layer height 0.25, extrusion width 0.5 mm, 3 perimeter, 2 bottom/top layer, 25% infill

All elevon parts: layer height 0.25, extrusion width 0.5 mm, 1 perimeter, no infill

elevon appendix: 4 top/bottom layer

elevon inner: 8 bottom layer, no top layer, spiral vase mode

elevon outer: 4 bottom layer, no top layer, spiral vase mode

elevon joint inner/outer: no bottom/top layer, spiral vase mode

fin: layer height 0.25 mm, extrusion width 0.45 mm, 5 bottom layer, spiral vase mode

/https://fbi.cults3d.com/uploaders/4244034/illustration-file/94b42148-8d5d-4d44-ac7b-c8f99ced418d/Delta_5b.jpg)