It's my second take on that theme after

Stevenson Screen 87mm (https://www.thingiverse.com/thing:4907550).

Same dimensions here but while the former was just a remix I recreated all elements here in freeCAD so tasks like i.e. adapting the thickness are much easier now.

I have my doubts regarding how long the prior version, done in PLA will stay stable under the sun's UV and hope TPU will do better in the long run. I have them both sitting on a window board, on the same side of the house. It will be interesting to compare how they perform over time.

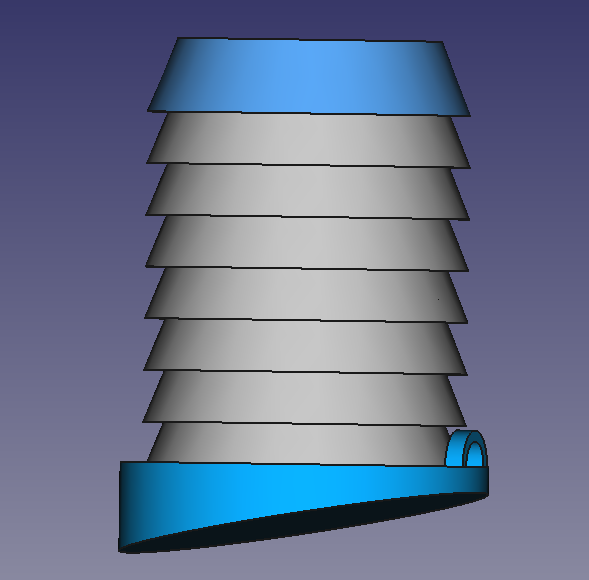

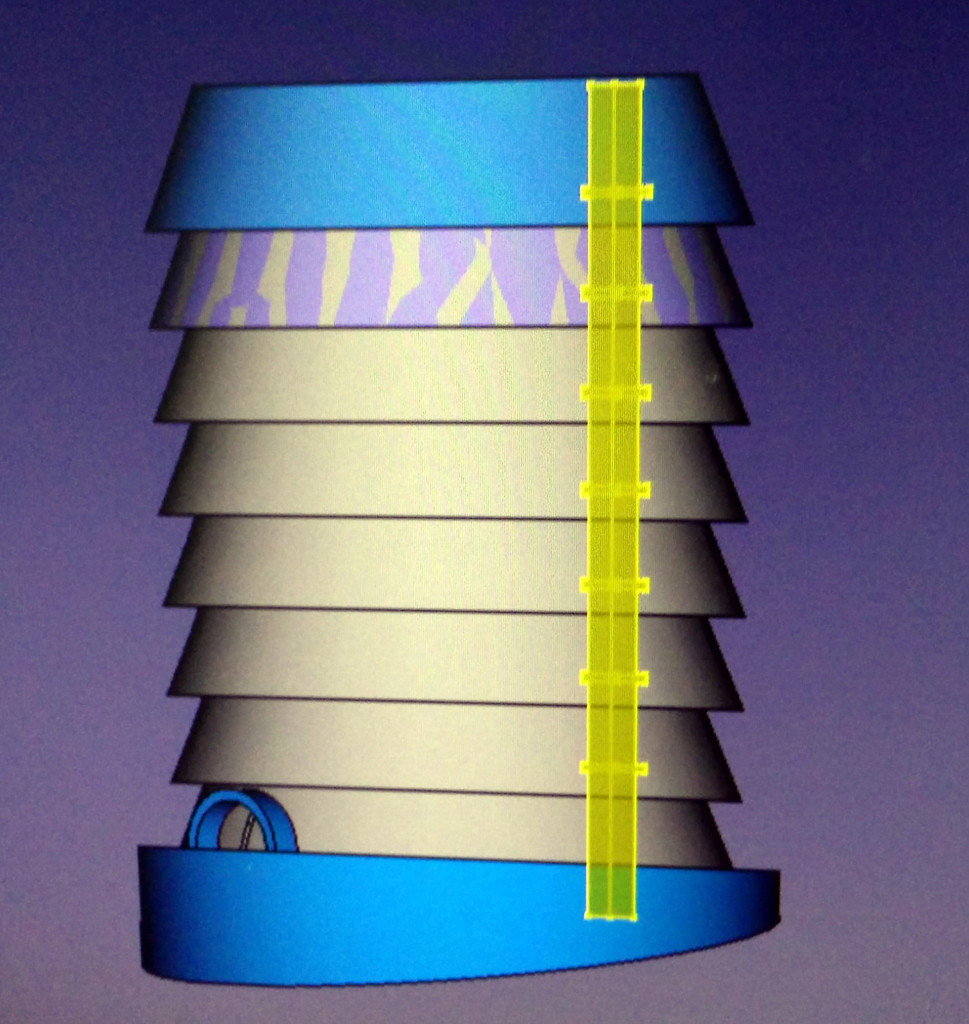

The construction was adapted to avoid all the stringing that comes with details in the model. Now the floors simply have 3 openings for central columns and not the three stands-with-hook like the former version had.

Instead there is a column which you print 3 times and which has rings on it that hold the floors. Those columns should be printed in PLA to give the whole thing better stability.

Those columns are based on cubes so they can be printed lying on the print bed which makes them more stable, too, and faster to print. Lay them on the flat side in the slicer.

As a consequence of having separate column elements the freedom to 'just add another layer' on the go is lost. The .stl are made for a top and 7 floors. The floor walls rise 20mm, floors follow each other at 14mm intervalls so there is an overlap of 6mm to keep the rain out. The floors have a diameter of 88 mm. the whole structure is 128mm at the middle.

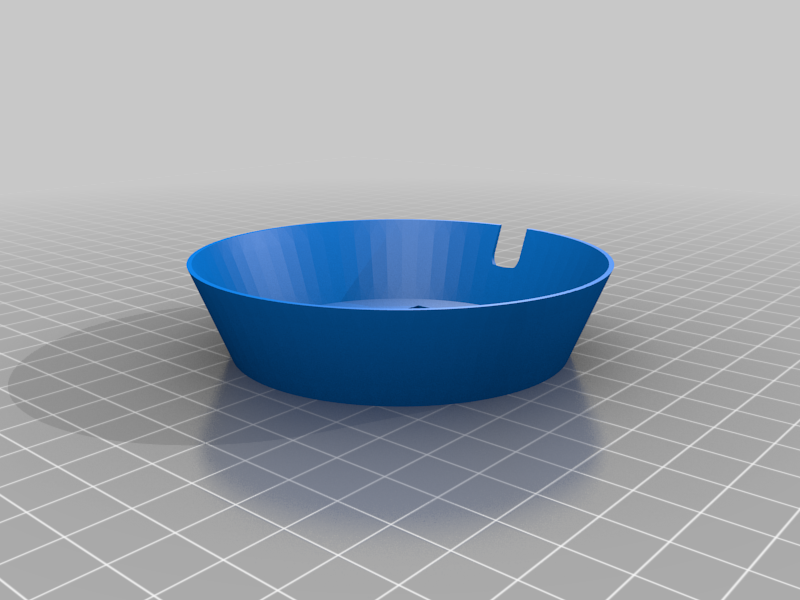

The top floor is different as it has pockets to hold the 3 columns. Then there is one floor with a hole at the side for a cable outlet. This floor should go close to the bottom. The outlet aligns with the ring on the bottom plate.

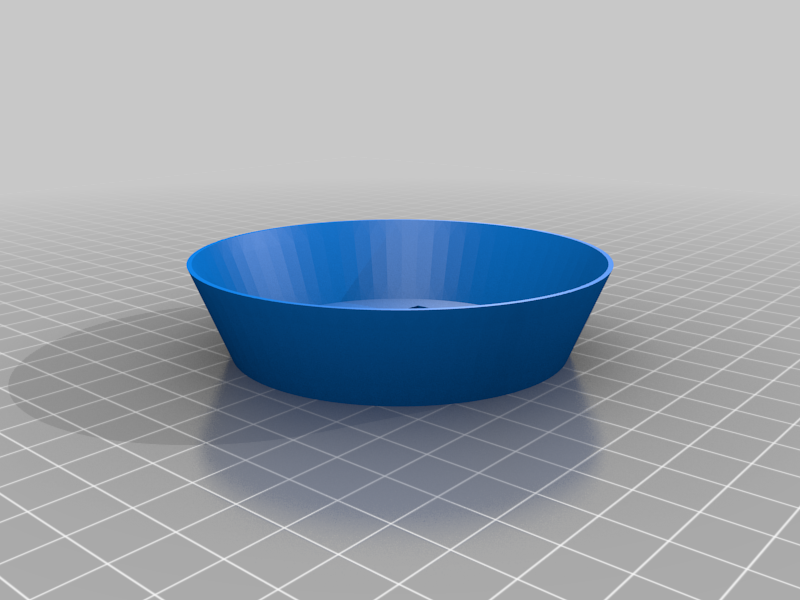

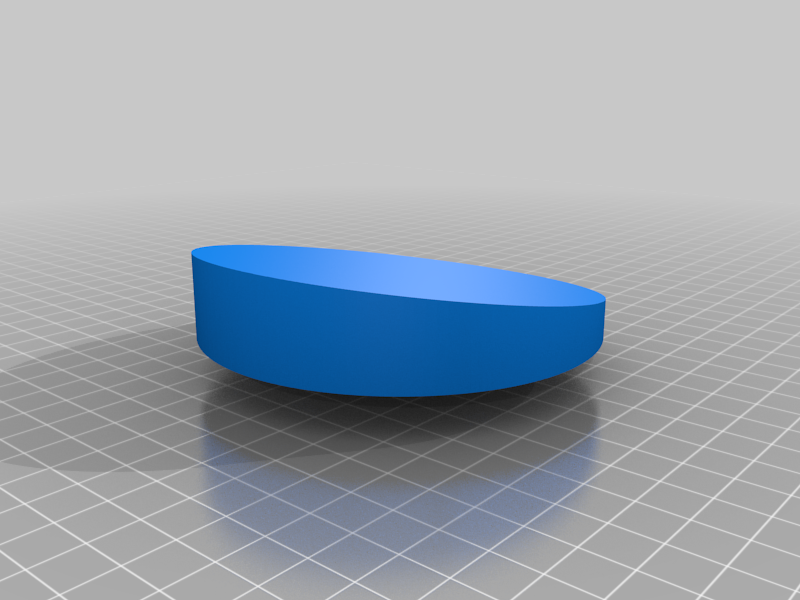

There is a bottom plate with a 10° inclination to fit on my window board. Turn it on the back in the slicer. And like with the other version you'll find an Y-shaped holder that will take an 8x Dupont pin. I plug the sensors directly into it so it gives both electrical and mechanical connection.

With everything printed and assembled the weather-pagoda weighs 116 gr.Top and bottom had a bit of stringing where parts stand out, the rest came out really clean.

Setting the floors on the columns will need a calm hand, it's tight. Be aware that the floors are 'orientation-aware', when you get it right the square holes align, if not things get twisted. The columns have a 'shorter' and a 'longer' end, the shorter end goes into the top, the longer into the bottom plate.

This thing will not work with PLA, it requires a flexible material.

As to print settings, TPU benefits from high temperature (235°C), uniform speed and continual feed. I set

- all speeds to 50, (steady flux)

- set the part fan to 0,

- 235° tool temp,

- 1.2 flow multiplicator,

- no retraction

- and I use prusa slicers 'avoid crossing' option.

- bed temp is still on 60° like with PLA but that is no so important

With TPU-friendly models like these I could probably go even higher with print speeds

FreeCAD (19) source is included, some things as thickness, number of floors, floor interval and screen height are parametric so you can adapt them easily.

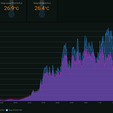

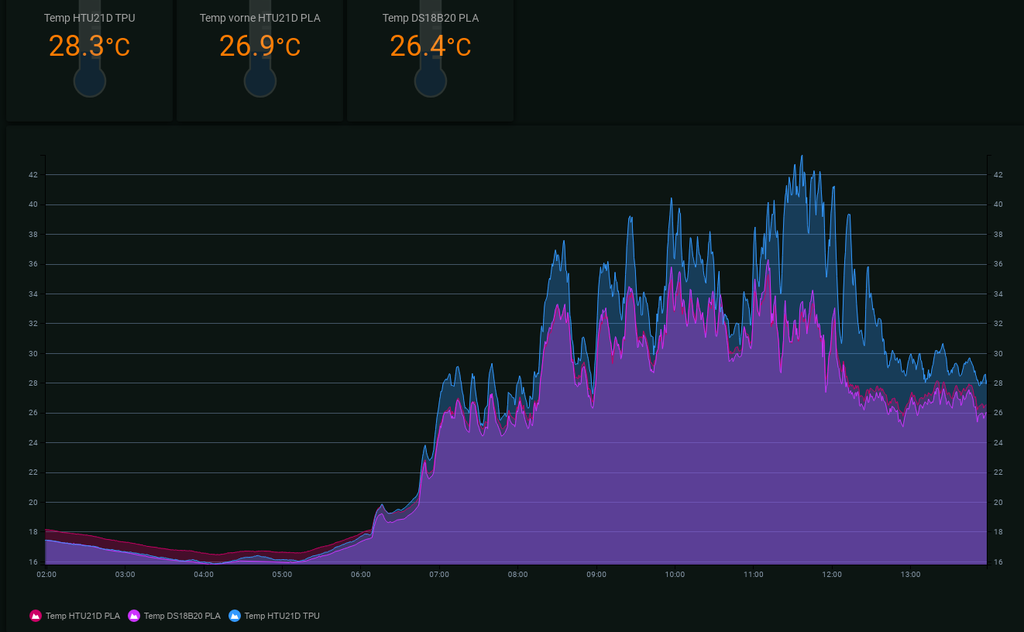

Compairing PLA and TPU:

I have 2 almost identical sensor cases, both just a window apart on the same side of the house, one in PLA, the other in TPU. I plotted the temperatures on a graph, during night * hours you see the sensor in the PLA case reports about 0,6°C higher temps than the other, the sensor in the TPU case and a DS18B20 sensor (as a control in the PLA case) report identical.

As soon as the *sun appears the picture changes. The sensor in the TPU case goes up and reports higher than those under PLA, and the more sun there is, the higher the difference.

After the sun weakrns, 18:00 at this time of the year, things reverse once again.

So this looks like a clear proof that PLA is better suited to isolate against heat from solar radiation than TPU. Didn't expect that, the tests on durability and rain resilience are

Update:

- turned the small ring at the base and the opening in the cable_floor to the other side.

- modified the holder to fit better to the columns

- the figurine on top is Mari Amman (https://www.thingiverse.com/thing:4611734), a Tamil goddess of rain and wealthyness.

/https://fbi.cults3d.com/uploaders/14815293/illustration-file/1199f1ec-5c5e-457d-a2de-05800422ca85/mariAmman.jpg)