This is a custom made air assist for a NEJE 30 watt laser. There are basically 3 print files. The first part is the mount to connect to the laser front replacing the colored acrylic that is standard on that module. This mount will hold the tube that is connected the nozzle and goes up to the collimator. The fit is friction and presses against the collimator snugly. The second part is the clamp that holds the nozzle/tube assembly that is hanging down from the mount that is on the laser. This clamp also holds the tube for feeding air to the nozzle when cutting/engraving. The last 3d printed part is the tube support that simply goes around the fan of the laser module to hold the air tube that runs up the side of the laser. This is shown in the included pictures.

Parts required:

The 3 STL files printed

mount for laser

clamp for tube and nozzle

mount for supporting the air tube

1 - 9mm O.D. x 5mm I.D. aluminum tube 29mm long tapped with m6 thread

1 - .8 mig welder nozzle with m6 thread for screwing into aluminum tube

1 - 4mm O.D. brass tube for air assist tube

1 - 2 ft length of 4mm ID clear air tubing (and air pump of choice)

1 - m3 x 10 bolt and nut

1 - m6 drill tap

1 - 5/32 drill bit (9/64 is slightly smaller but could work for nozzle hole in length and side)

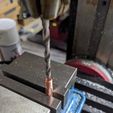

Drill the .8 mig welder nozzle out using either a 5/32 or 9/64 drill bit (preferred 5/32) to enlarge the nozzle for air flow. Drill the side of the nozzle on one of the flat sides using the same 5/32 bit for the air tube to supply air to the nozzle.

Screw the nozzle and 29mm length 9mm aluminum tubing that was tapped with m6 threads together.

Slide the nozzle into the 3d printed clamp piece until the aluminum tube stops at the shoulder inside the clamp.

Turn the tubing and nozzle until the hole in the side of the nozzle aligns with the hole in the side of the clamp piece. Using a 3mm x 10 bolt and nut, tighten onto the tube to keep it from turning.

Using about a 6 inch piece of 4mm brass tubing insert a heavy piece of copper wire into the tube and bend a sweeping curve until it is at about 45 degrees.

Insert the short side of the brass tube into the slanted hole of the clamp piece on the tube and gently work it into the hole until it reaches the bottom.

Turn the tubing to face upward along the side of the laser.

Now slide the tube into the laser support mount but don't push it all the way up yet.

Now put the mount onto the front of the laser module where the colored acrylic was and replace the 4 bolts to hold it in place.

Slide the tube (along with the air feed tube) all the way up to meet the collimator. Turn the tube and clamp until the slanted hole and tube run up and parallel with the front right edge of the laser module.

Slide the hole in the fan mount 3d printed piece onto the brass tube and slide it down until the bracket can be placed around the laser fan shroud to support the brass tube.

Double check and ensure that the nozzle and aluminum tube are still pushed up against the collimator.

Attach a 4 mm air hose with a length of your choosing to the brass tube and the other end to a small air pump of your choosing.

That should do it and you should now have a direct air feed onto the part being cut by your laser. With my setup and focused, I still have about 6mm of clearance from the end of the nozzle to the top of the wood pieces I am burning or cutting. Yours may vary somewhat.

Note: The aluminum tubing I used is how the size of the 3D mount for the laser module is sized, so it needs to be that size to have the snug fit described. Anything else may require putting in some kind of lock screw in the laser mount, etc. to hold it firmly. Also the internal size of 5mm is necessary so the m6 drill tap can cut the threads. So that size might be fudged a little so long as the m6 threads can accept the nozzle and hold it with the threads.

The brass tubing can be obtained at Hobby Lobby craft store or here on Amazon

https://www.amazon.com/Engineering-Round-Brass-Tube-45/dp/B005WPAQSO

The aluminum tubing found here on Amazon

https://www.amazon.com/uxcell-Seamless-Aluminum-Straight-Tubing/dp/B07W973RGX/ref=psdc_16414261_t2_B07WLN69T1?th=1

The m3 bolt and nut can be found in an assortment pack unless you already have some

https://www.amazon.com/DYWISHKEY-Pieces-Socket-Screws-Wrench/dp/B07VRC5RJ8/ref=sr_1_4?keywords=3mm+cap+head+screw+and+nut&qid=1637634541&qsid=139-4555681-1927526&s=industrial&sr=1-4&sres=B072FKMYMF%2CB07VRC5RJ8%2CB07L65DHV6%2CB078V73NN1%2CB07J3J92H6%2CB07HQC1CYF%2CB075QKQGTD%2CB076GZQXHB%2CB089GJ9SJT%2CB07VNDFYNQ%2CB081DS3QVT%2CB0897LF47G%2CB07S1R8NL7%2CB0761PKYR6%2CB0811NDFNJ%2CB07VT199JR%2CB07VRC6DHD%2CB01J7NM9JA%2CB083Q7ZR7D%2CB07VPGQ1RZ&srpt=SCREWS

The .8 nozzles are like these

https://www.amazon.com/gp/product/B07YV962RS/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

Enjoy.

/https://fbi.cults3d.com/uploaders/15172219/illustration-file/79a97dff-a0f3-4e1f-a7dc-8650483acb20/assembled_nozzle_on_laser_with_support_tube.jpg)