3D model description

English text on the end.

Umbau einer Proxxon MF70 Fräse auf CNC Betrieb mit Arduino Uno und NEMA17 Schrittmotoren.

Ihr braucht:

Erstmal ein wenig Geduld, so ein Umbau geht nicht in wenigen Stunden.

1 x Proxxon Microfräse MF70

3 x NEMA17 Schrittmotoren mit ca 45NM Haltekraft ( zB Ebay # 114059862538)

3 x Endschalter (zB Ebay # 111070309129)

4 x Achsial Kugellager (zB Ebay # 251363904925)

3 x Wellen Kupplungen 5mm auf 4,5mm (hab ich mit der FD150 selber aus Alustangen gedreht)

1 x Arduino UNO mit Shield CNC und Treibern ( Ebay # 274159362369)

Ein Netzteil das 12 bis 20 Volt liefert bei min 5 A ( mein altes Funknetzteil geht klasse )

Und natürlich einen PC mit Software. Ich habe die ersten Teste mit GRBL und SerialComCNC gemacht (https://www.mikrocontroller.net/topic/345380?page=8#6306227) für die weiteren Schritte benutze ich nun Estlcam (https://www.estlcam.de/).

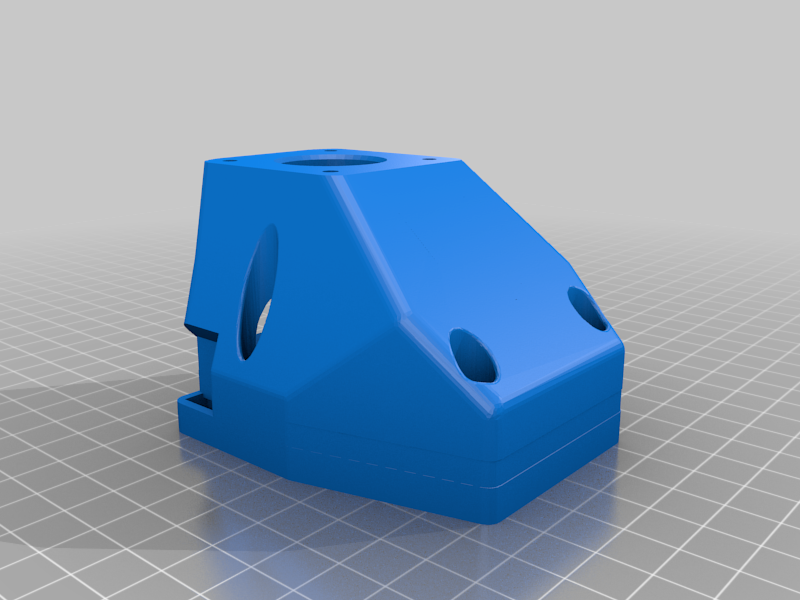

Zum Umbau: der Kreutztisch brauch an beiden Enden neue Halter, die Kurbeln müssen weichen um die Schrittmotoren aufzunehmen. Für den Kreutztisch werden 4 Teile ais dem 3D Drucker gebraucht die beiden Endteile gibt’s HIER

( x und y Endplate stl https://www.thingiverse.com/thing:4013033/files )

Die Halter für die Steppermotore in X,Y und Z findet ihr HIER https://www.thingiverse.com/thing:4528631

Des Weiteren habe ich die Fräse mit einem Zyclon Sauger ausgestattet. Die Bauanleitung ist HIER (https://www.thingiverse.com/thing:3263079) Das Ding funktioniert perfekt :-)

Ich habe mit einem Ender 3 gedruckt, 0,16 und 33% Infield, Support nicht vergessen !!!

Der nette Nebeneffekt ist das sich die Y Achse der MF70 Fräse auch ca 70 mm erweitert. Der Tischüberhang fällt nicht negativ auf.

Conversion of a Proxxon MF70 milling machine to CNC operation with Arduino Uno and NEMA17 stepper motors.

You need:

First of all, a little patience, such a conversion is not possible in a few hours.

1 x Proxxon microfiller MF70

3 x NEMA17 stepper motors with approx. 45NM holding force (e.g. Ebay # 114059862538)

3 x limit switches (e.g. Ebay # 111070309129)

4 x axial ball bearings (e.g. Ebay # 251363904925)

3 x shaft couplings 5mm to 4.5mm (I turned the aluminum rods myself with the FD150)

1 x Arduino UNO with Shield CNC and drivers (Ebay # 274159362369)

A power supply that delivers 12 to 20 volts at 5 amps (my old wireless power supply works great)

And of course a PC with software. I did the first tests with GRBL and SerialComCNC (

https://www.mikrocontroller.net/topic/345380?page=8#6306227

) I use Estlcam for the next steps (

https://www.estlcam.de/

).

For conversion: the cross table needs new holders at both ends, the cranks have to give way to accommodate the stepper motors. For the cross table 4 parts are used as the 3D printer, the two end parts are HERE

(x and y endplate stl

https://www.thingiverse.com/thing:4013033/files

)

The holders for the stepper motors in X, Y and Z can be found HERE

https://www.thingiverse.com/thing:4528631

I also equipped the router with a Zyclon vacuum cleaner. The building instructions are HERE (

https://www.thingiverse.com/thing:3263079

) The thing works perfectly :-)

I printed with an Ender 3, 0.16 and 33% Infield, don't forget support !!!

The nice side effect is that the Y axis of the MF70 milling machine also extends about 70 mm. The table overhang is not noticeable.

/https://fbi.cults3d.com/uploaders/13976919/illustration-file/d8adeaab-59b2-4bb2-a055-677a20856128/MF70toCNC_Nema17_Z.png)