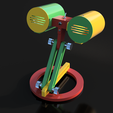

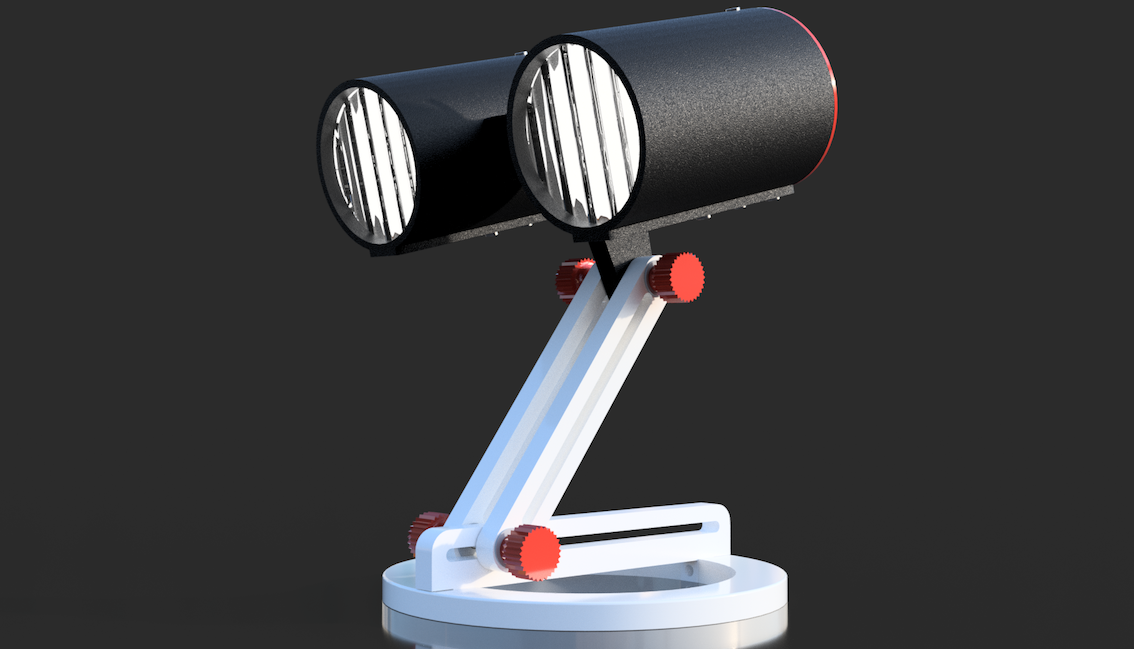

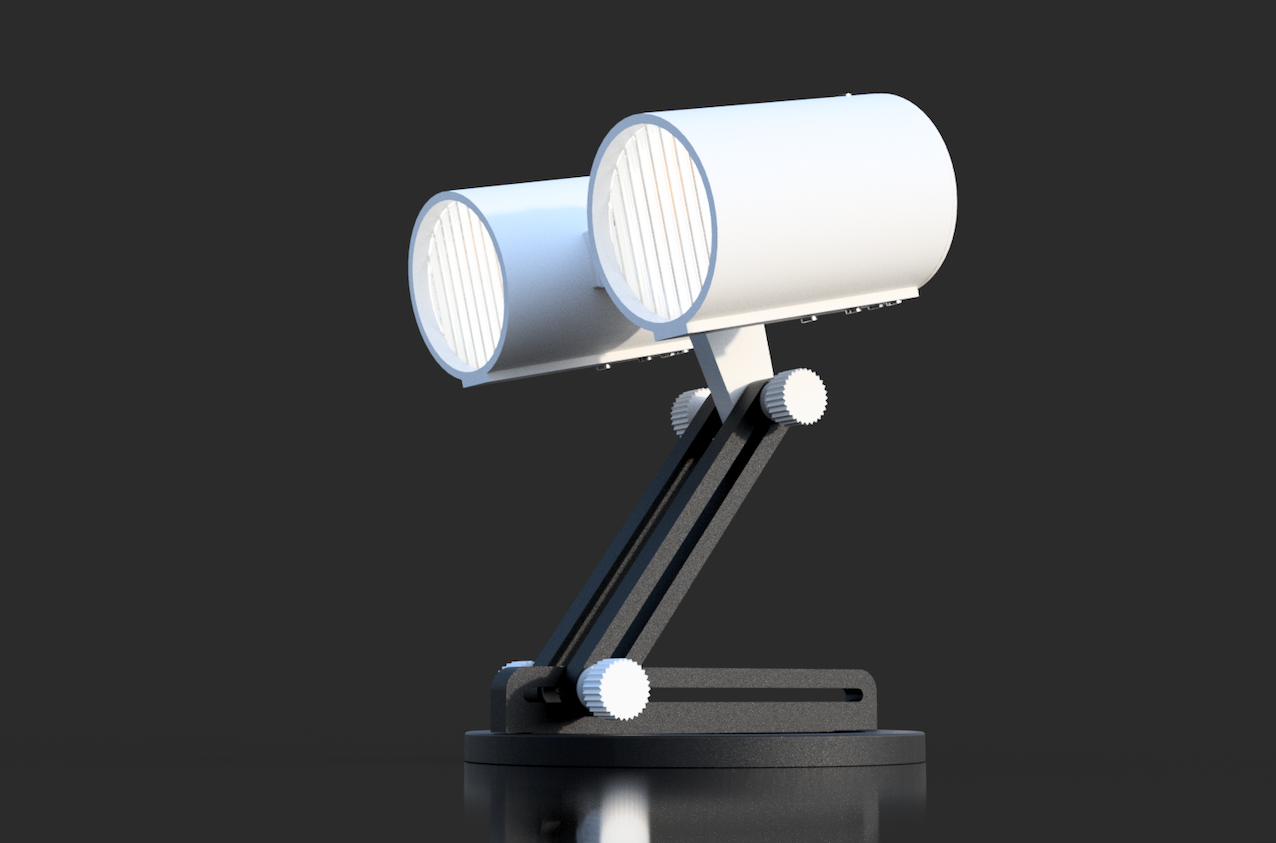

I already have some lamps printed and in use here at my place. Inspired by the contest on www.instructables.com on the subject of lamps, I have designed this lamp.

As with some of my other projects you need a little bit of craftsmanship here too, a.o. soldering.

As the name "Duolux" suggests, this project involves two light sources. A further development of my project Bedside Lamp "Tube", but because of the two light sources with of course a double light output (with 2x 250 lumens). With 3000K the light is considered warm white. The power consumption is 2.5 watts for each LED unit.

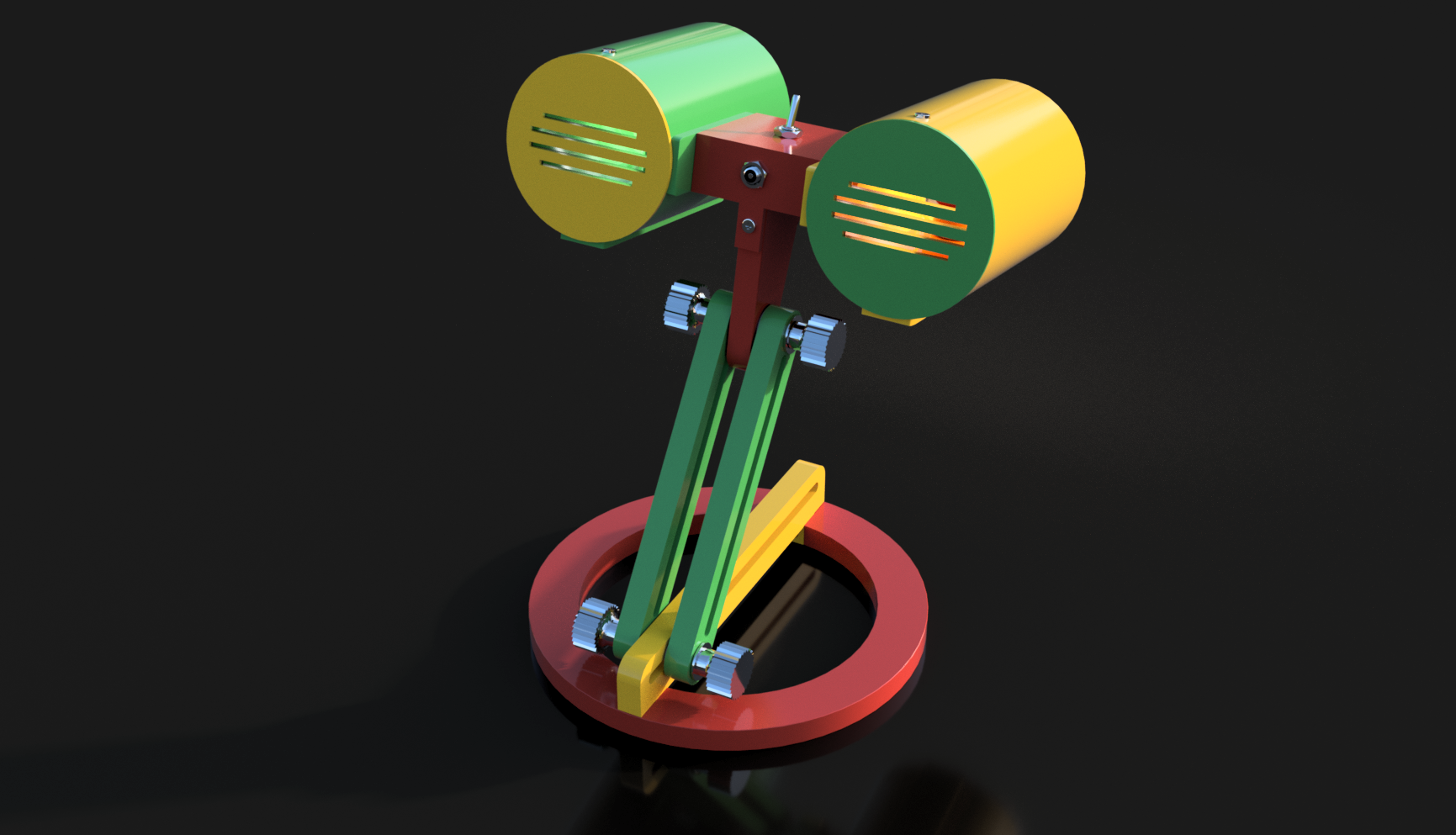

In colorful version, it can also serve well as a children's room lamp.

A self-printed lamp, with individual coloring, is always something special!

Dimensions:

H 245 mm

W (socket) 160 mm

W (both tubes) 195 mm

L (tubes) 102 mm

Files to print:

Lamp DuoLux_tuberight.stl

Lamp DuoLux_tubeleft.stl

Lamp DuoLux_basering.stl

Lamp DuoLux_back.stl (2x)

Lamp DuoLux_centralmount.stl

Lamp DuoLux_centralmounttop.stl

Lamp DuoLux_knob.stl (4x)

Lamp DuoLux_ledsocket.stl

Lamp DuoLux_leg.stl (2x)

Lamp DuoLux_sliderail.stl

Lamp DuoLux_glassfixingring.stl (2x)

Remark: As all parts are designed to fit very precisely, it may happen that you have to rework one or the other part a bit with sandpaper and/or cutter due to different dimensional accuracy of the printers and the different behavior of the filaments.

Supplies

For this project you will need:

2x ... Ø 65 mm polycarbonate twin-wall sheet, thickness 6mm or 4mm (or white polycarbonate glass 3mm thick, 70% translucency or transparent polycarbonate glass)

2x ... Ø 4x45mm from a threaded rod (or screw Ø m4 x 50 and saw of the screw head)

10x ... Ø M3x15mm + plus matching nuts (to connect tubes with central mount and LED base to tube)

4x ...nuts Ø 4mm (for the knobs)

8x ... washers Ø 15x4,5mm

11x ... self-tapping screws Ø 2.2x 9.5mm

switch wire, approx. 10cm (5cm black, 5cm blue, for a better recognition when wiring)

(4x ... self-adhesive rubber pads Ø 8x1mm)

2x small luster clumps

Drill, Ø 2mm

Fretsaw

Soldering Iron

Solder

(Super)glue

Sandpaper

Phillips screwdriver

piercer

For the light installation you need:

AC/DC Socket 5.5/2.1mm

4G bulb socket (2x)

2 position mini toggle switch

4G LED bulb 2.5W/250Lm (2x) IMPORTANT!: I do not advise the installation of a higher wattage bulb, because of too much heat development!

12 V AC/DC power adapter

Some of these parts you can find here:

Light: Trango 3-pack LED bulb with G4 socket to replace the G4, MR16, GU5.3 halogen bulb TGG415-2.5W - 12V AC/DC - 2.5 watts 250 lumens with 3000K

https://www.amazon.de/dp/B00LC0DSEC/ref=cm_sw_em_r...

Bulb socket: 10pcs MR16 GU5.3 MR11 GU4 socket 12V with cable.

https://www.amazon.de/dp/B00279SBDA/ref=cm_sw_em_r...

Power adapter: LEICKE power adapter 12V 2A | 12V 2000mA | charger 24W for LCD, LED strip https://www.amazon.de/dp/B00LEFGDOM/ref=cm_sw_em_...

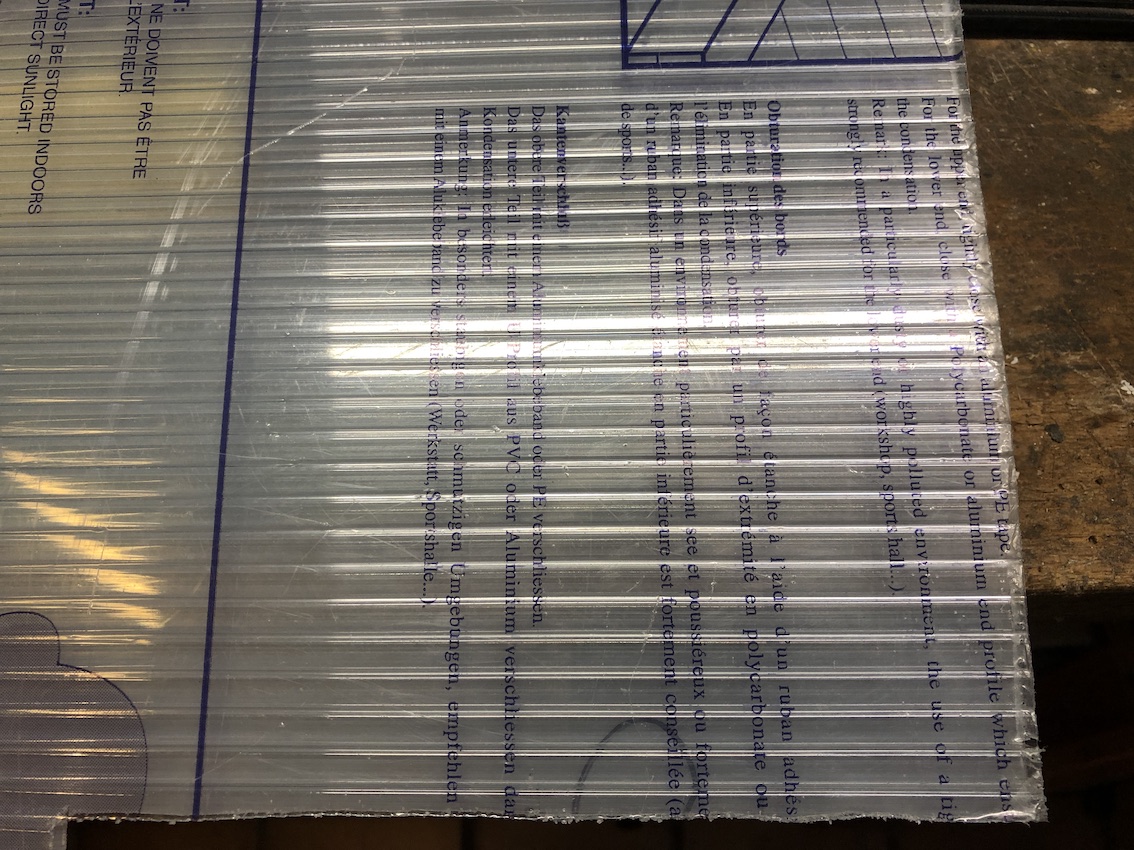

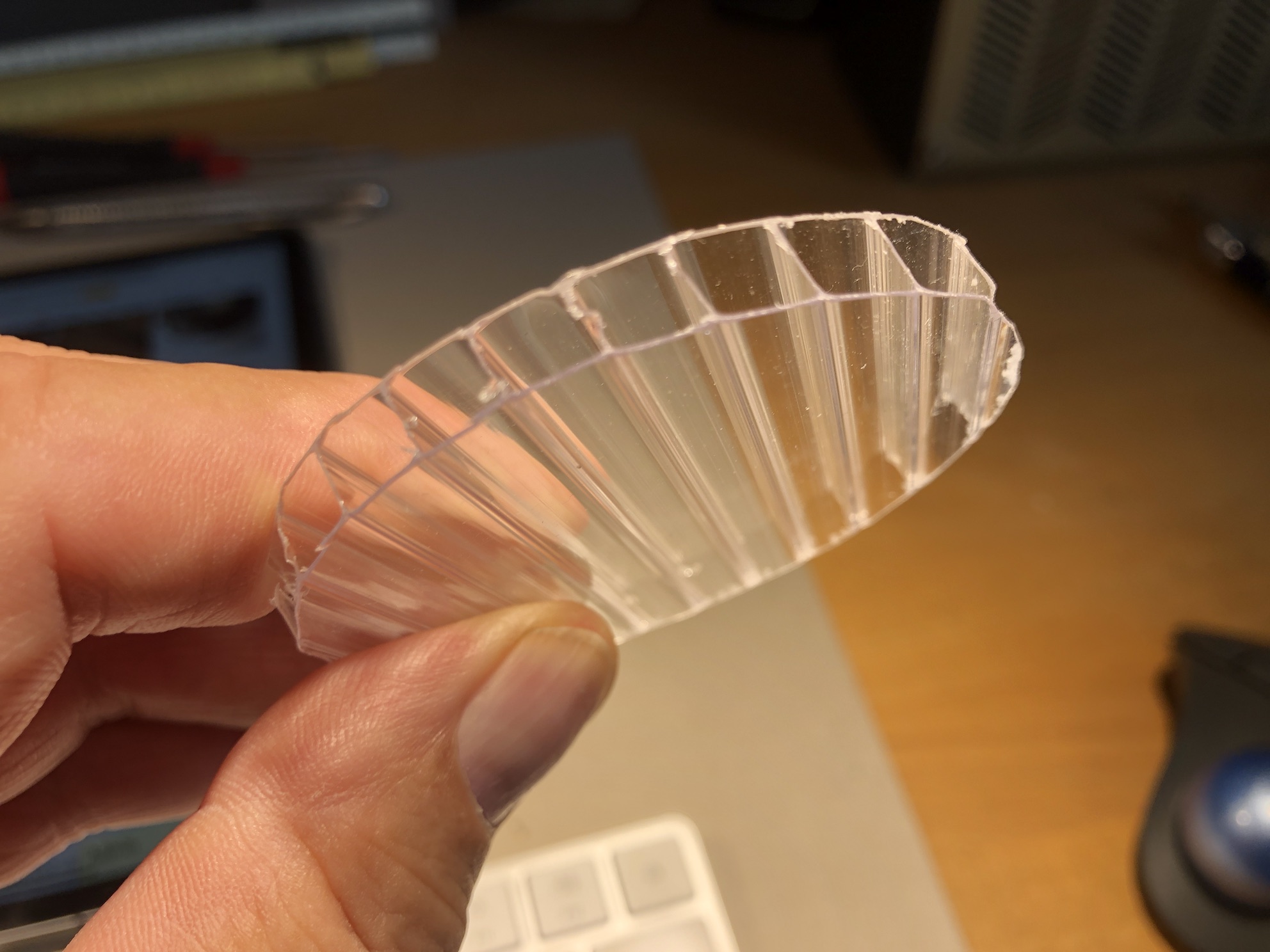

Step 1 - Sawing Lamp "Glasses" From a Polycarbonate Twin-wall Sheet

There is hardly anyone who will have a polycarbonate twin-wall sheet in stock at home, and no one is likely to buy a whole 1m x 2m sheet just for a few square centimeters. Perhaps there are similar sheets in smaller sizes. Otherwise I recommend polycarbonate glass 3mm thick, 70% translucency or transparent polycarbonate glass. These are available in our DIY stores in small sizes.

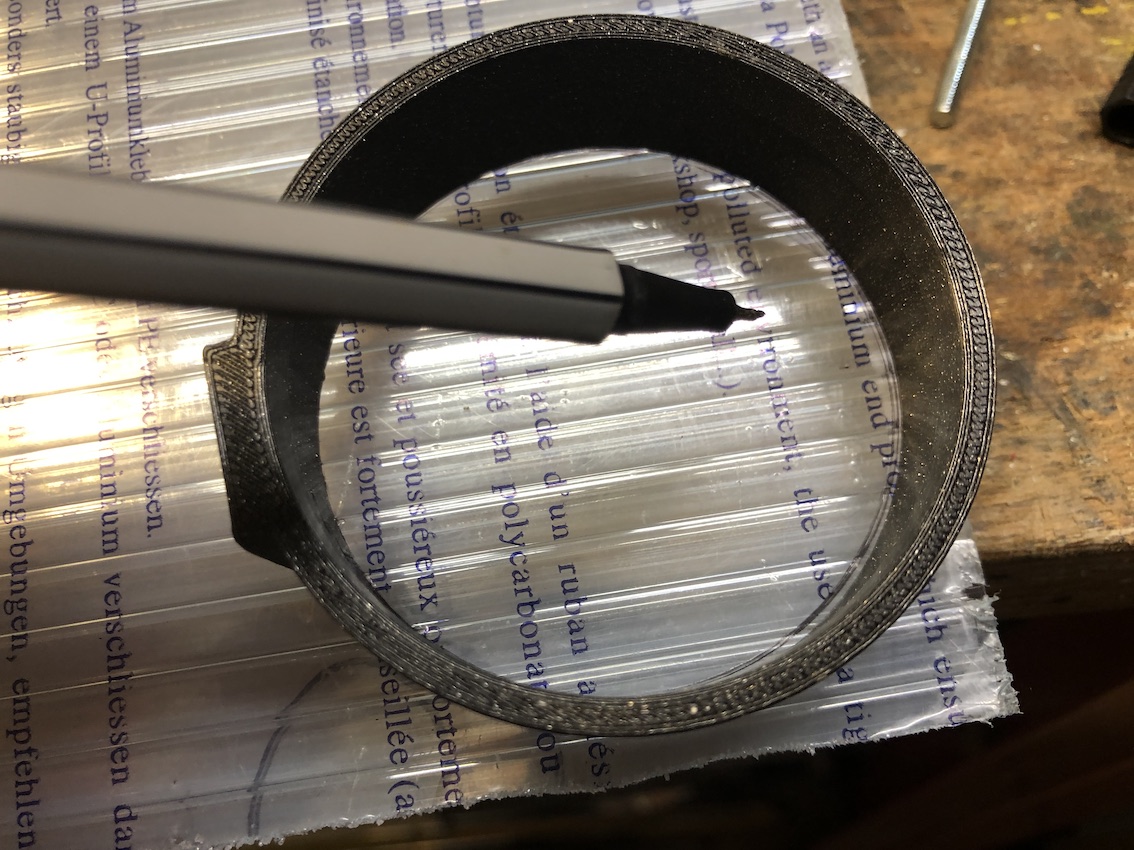

After you have printed all the parts, you can start sawing out the lamp "glasses". I sawed out small plates Ø 65mm from a twin-wall sheet, 6 mm thick. I used a fretsaw with a very fine saw blade. Before that I drew the circle with the help of the inner back (!) of a lamp tube.

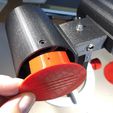

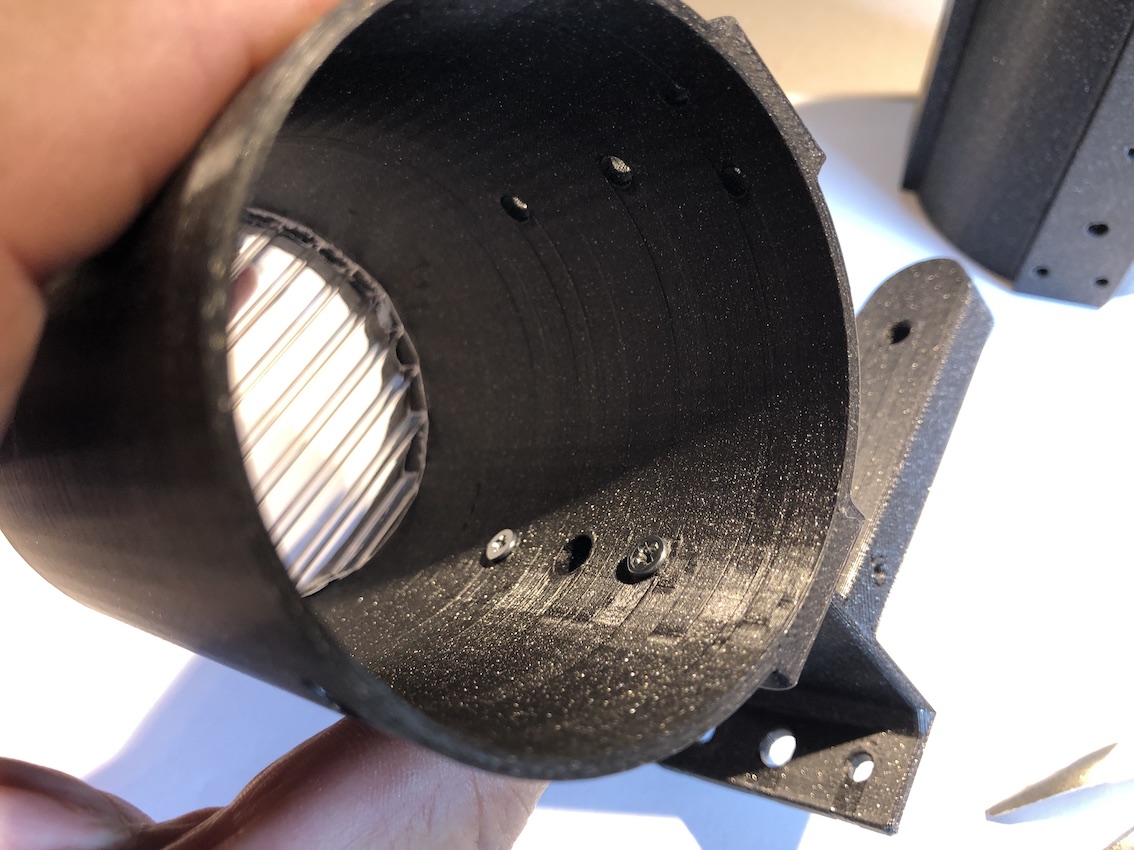

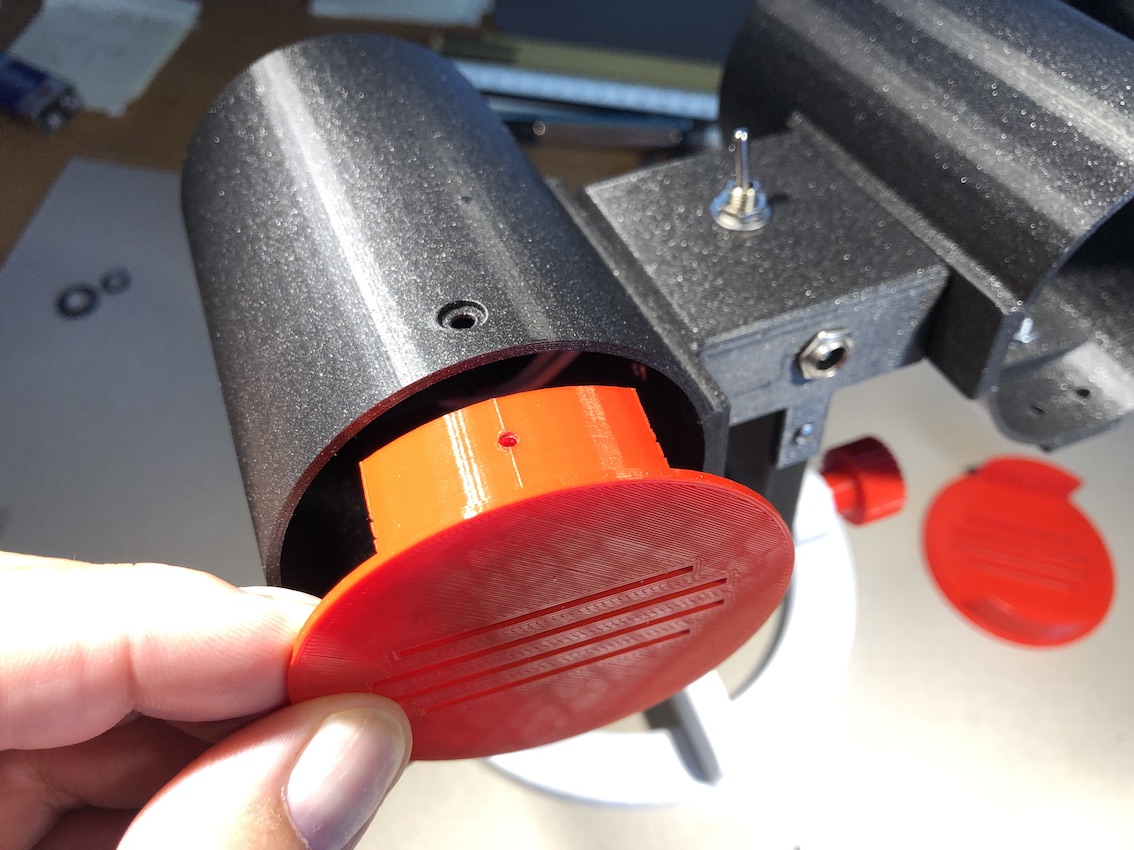

Step 2 - Inserting Twin-wall Sheet "glasses

For this step you need:

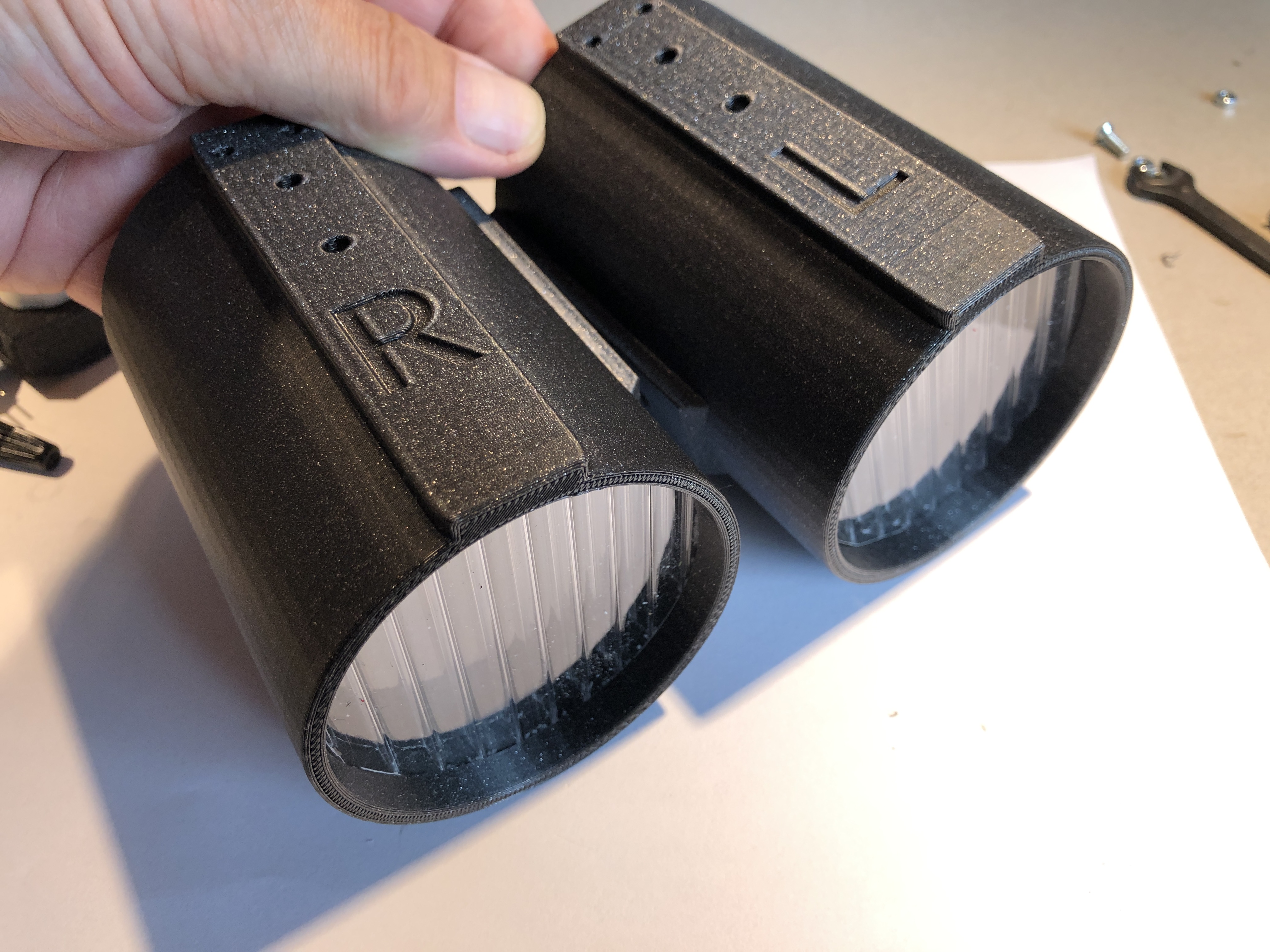

I started with" Lamp DuoLux_tuberight.stl".

It was not so easy to insert the multi-wall sheet glasses so that the lines were exactly vertical.

After I finally succeeded, I pushed in the glass fixing ring. It sits very tightly. That is the intention. This is additionally fixed with a little super glue.

Do the same with "Lamp DuoLux_tubeleft.stl".

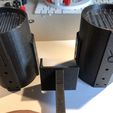

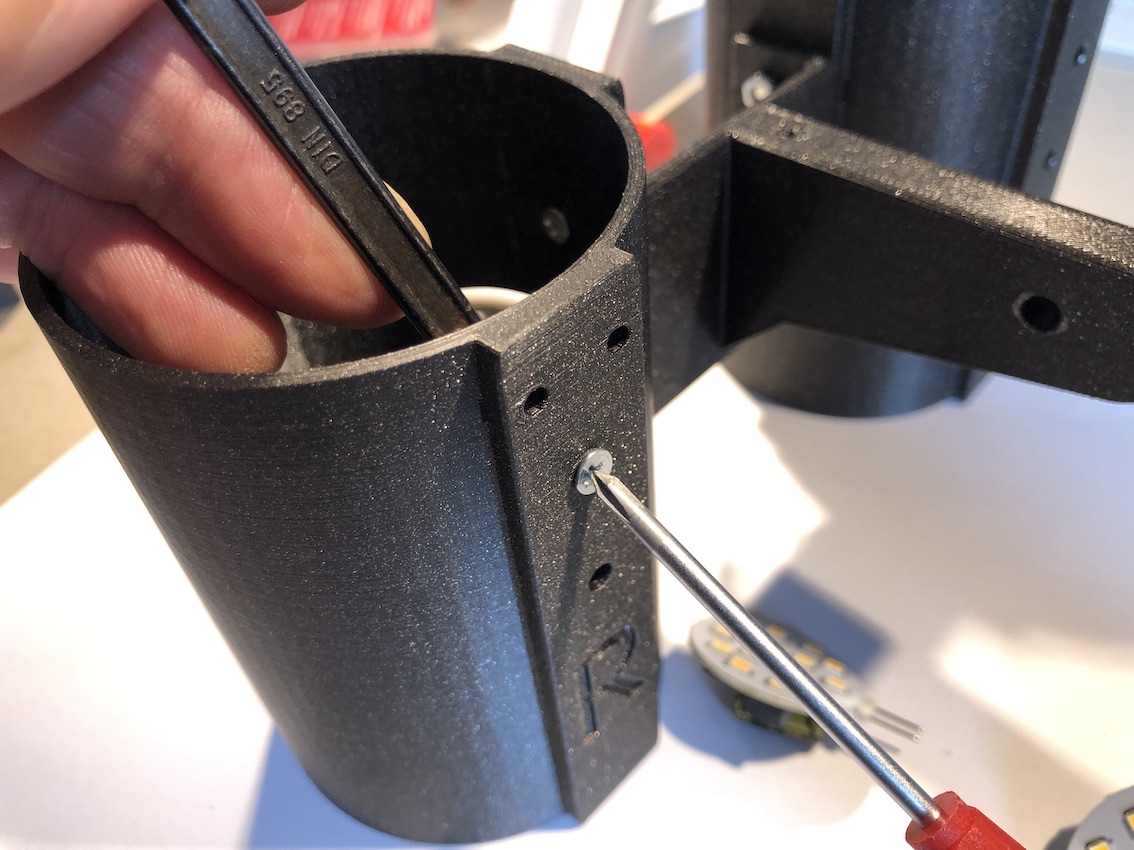

Step 3 - Assembling Light Units

For his step you kneed:

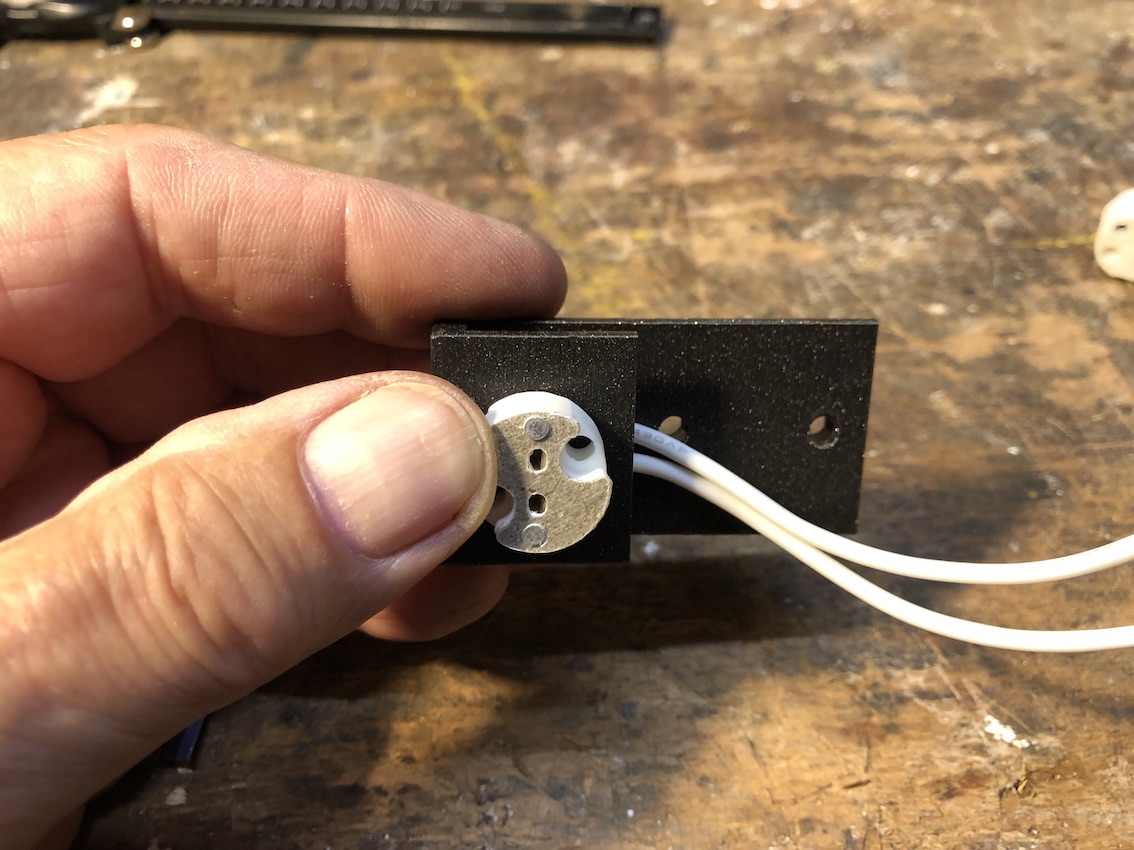

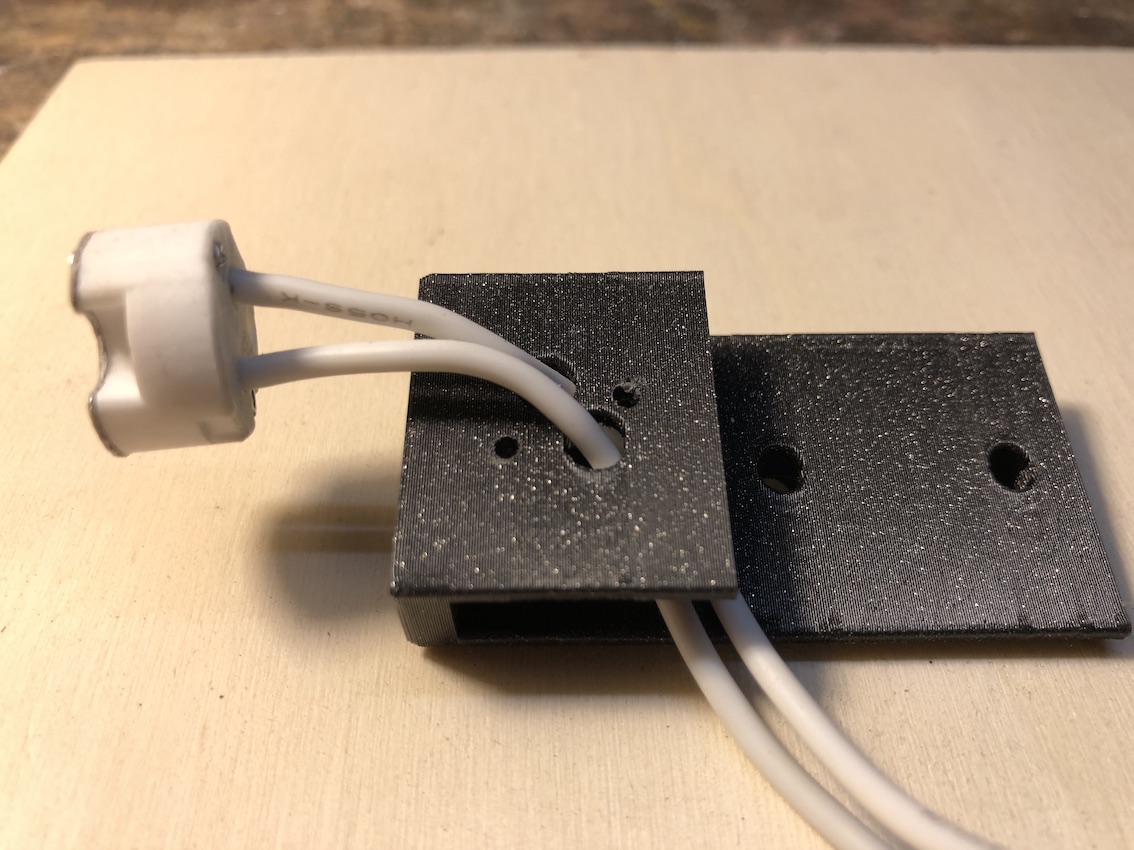

The LED bulb socket must be screwed onto the "Lamp DuoLux_ledsocket.stl". For this you have to drill two holes with Ø 2mm into the socket. Before you do this, mark the holes with a pointed object.

Do the same with the second one

Step 4 - Inserting LED sockets

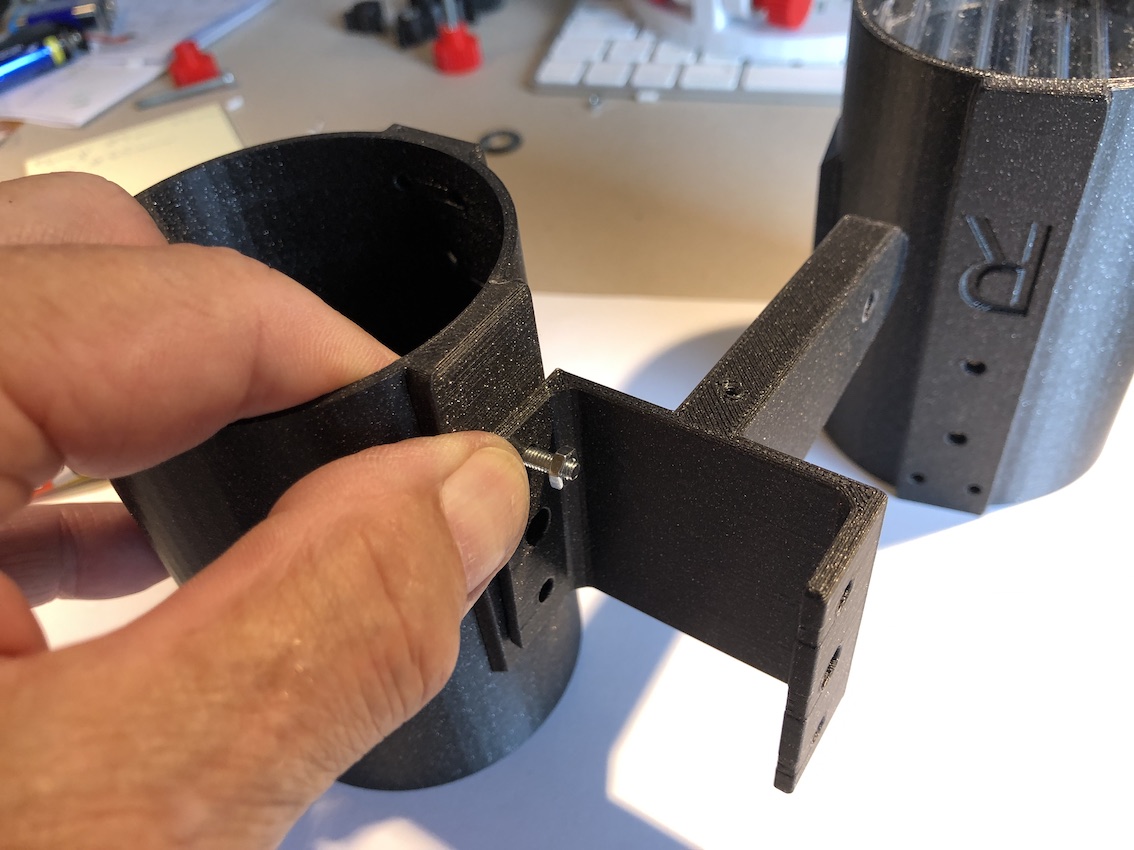

To connect both LED sockets to the tubes you need

- 4x Ø M3x15mm + plus matching nuts.

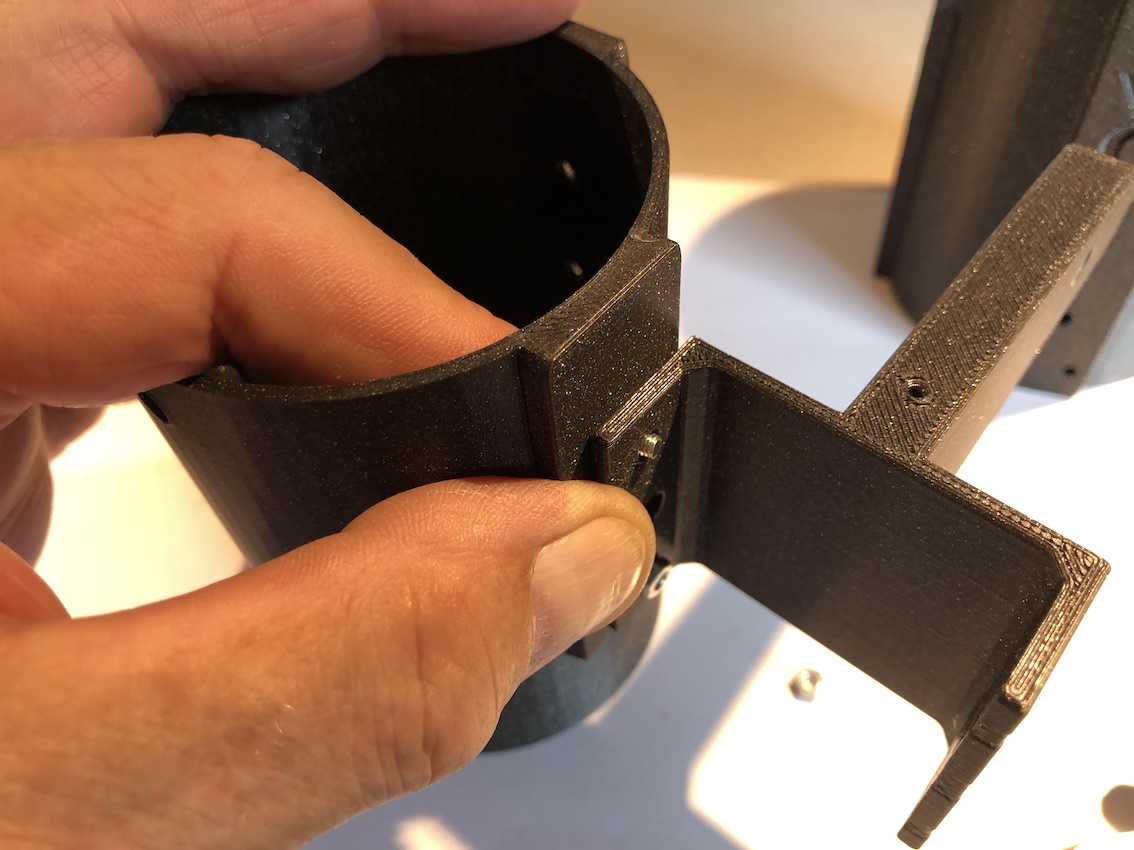

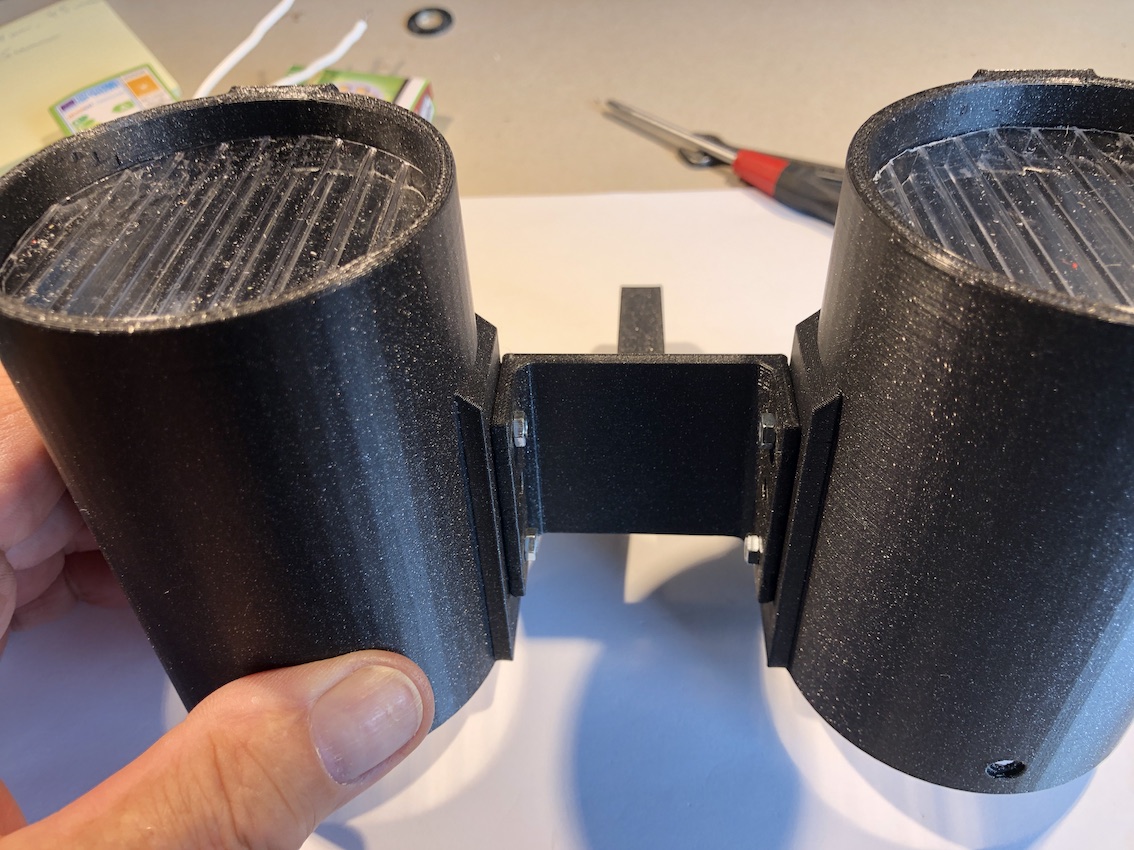

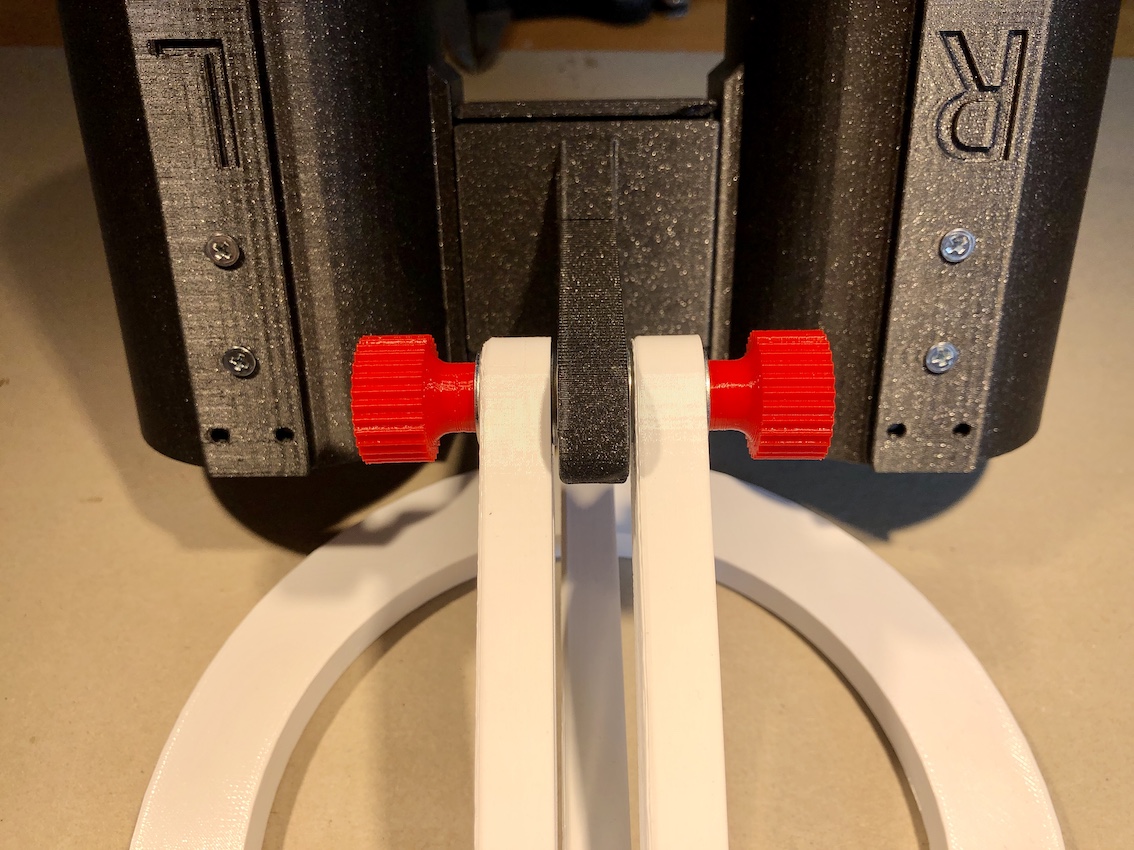

Step 5 - Connecting Tubes to Central-mount

For the next step you need:

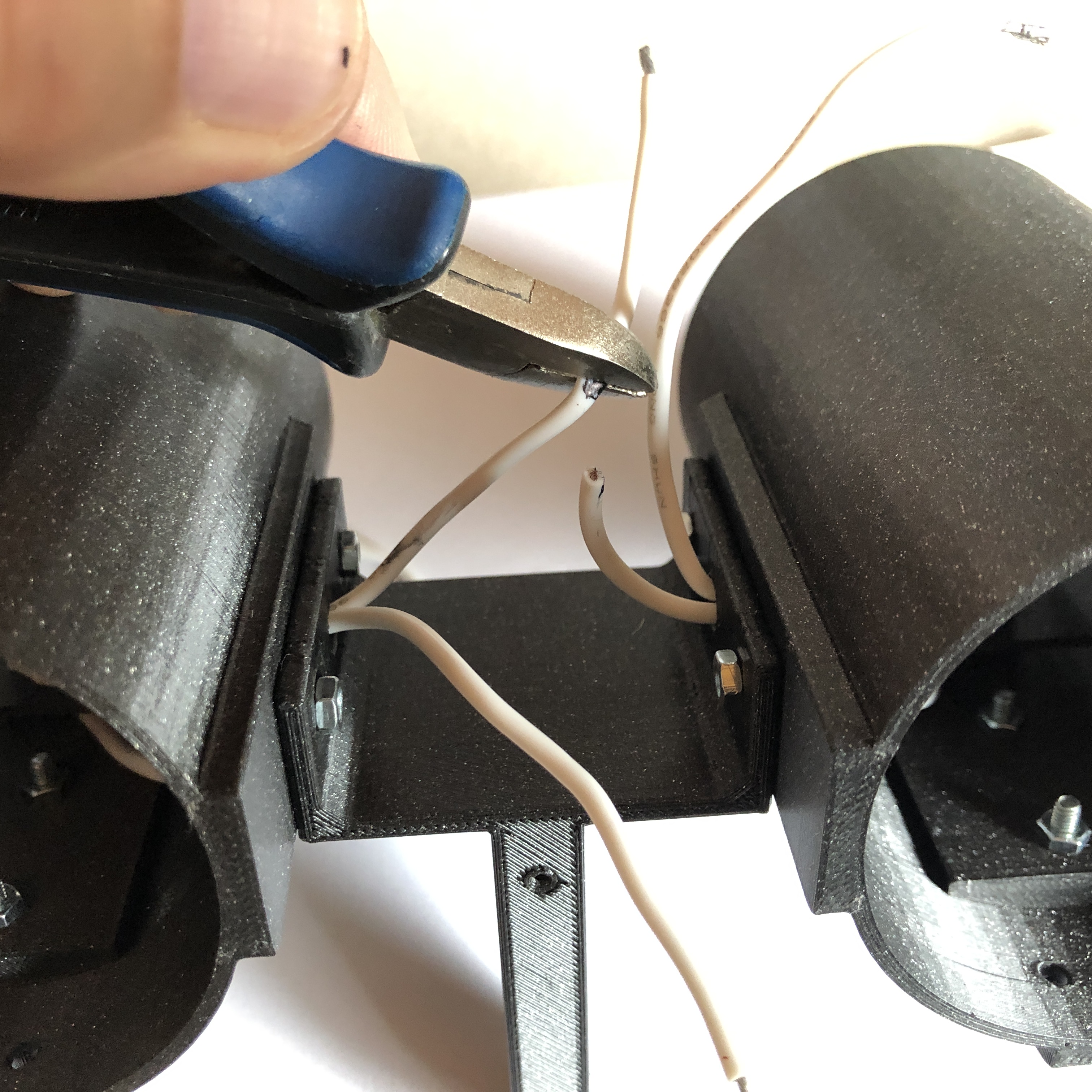

The marks L and R on the bottom of the light tubes are seen from the front, from the light side!

In my case I have taken shorter screws (4x Ø m3x10mm). They are very short in length. Therefore, I recommend to take longer screws.

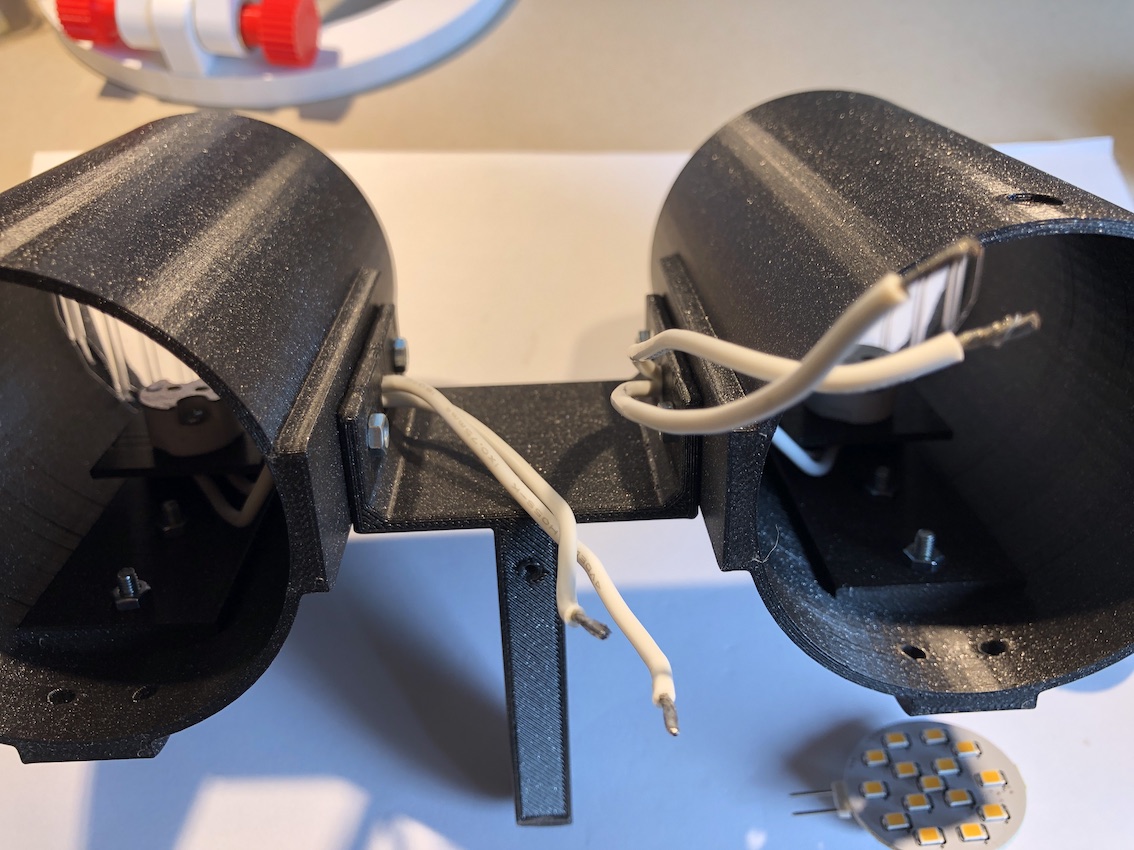

Step 6 - Preparing Electrics

For this step you need:

First you can start inserting the 4G LED bulbs (2,5W/250Lm). I did it carefully with pliers.

IMPORTANT!: I do not advise the installation of a higher wattage bulb, because of too much heat development!

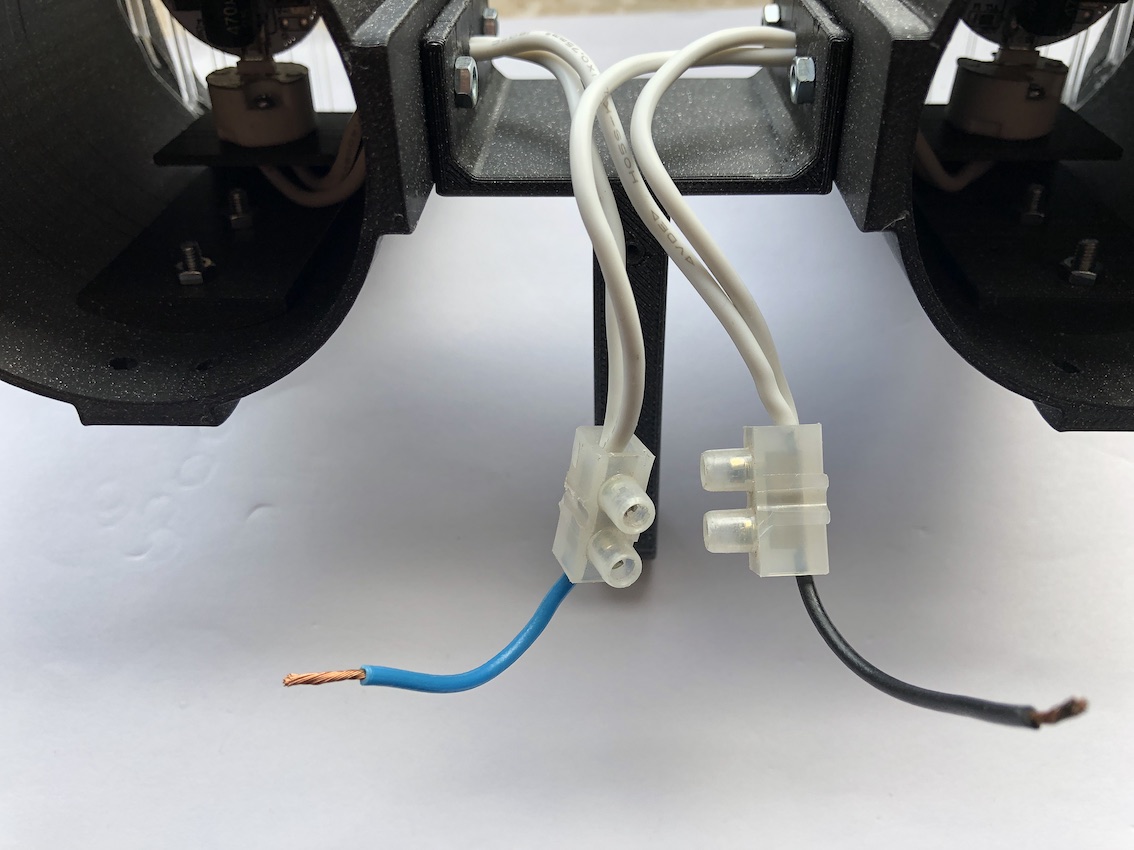

Next, the cables should be shortened a bit. But only so far that the cable ends still reach into luster clumps. Afterwards the cable ends must be stripped.

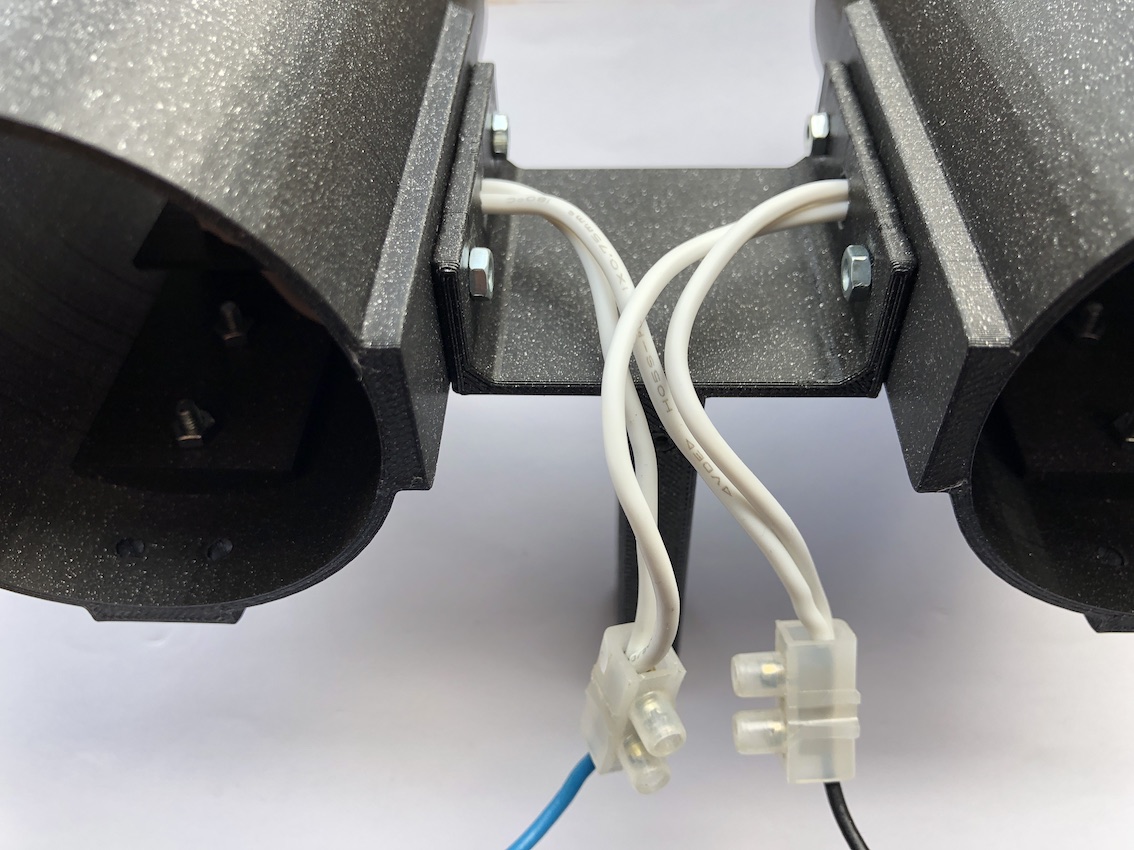

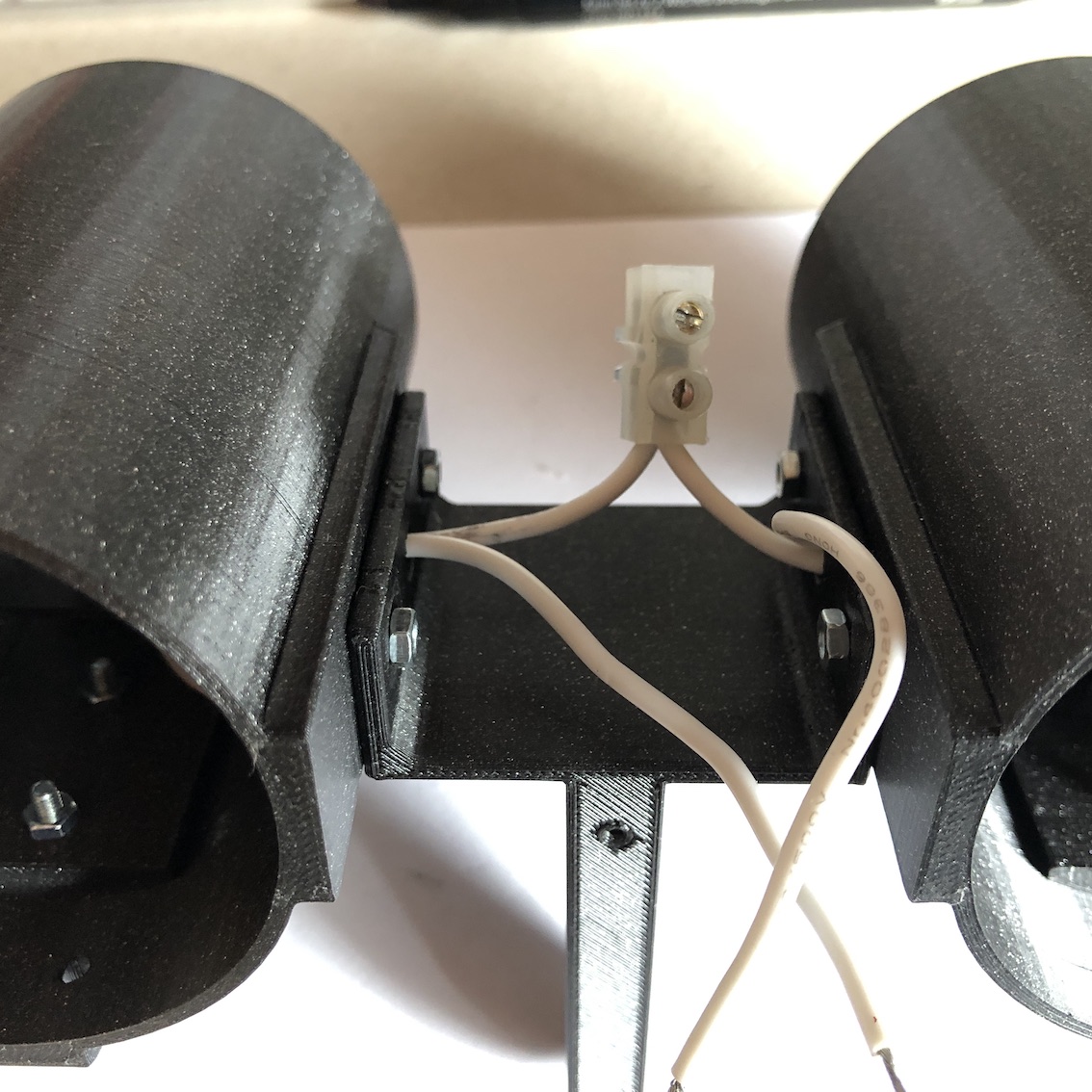

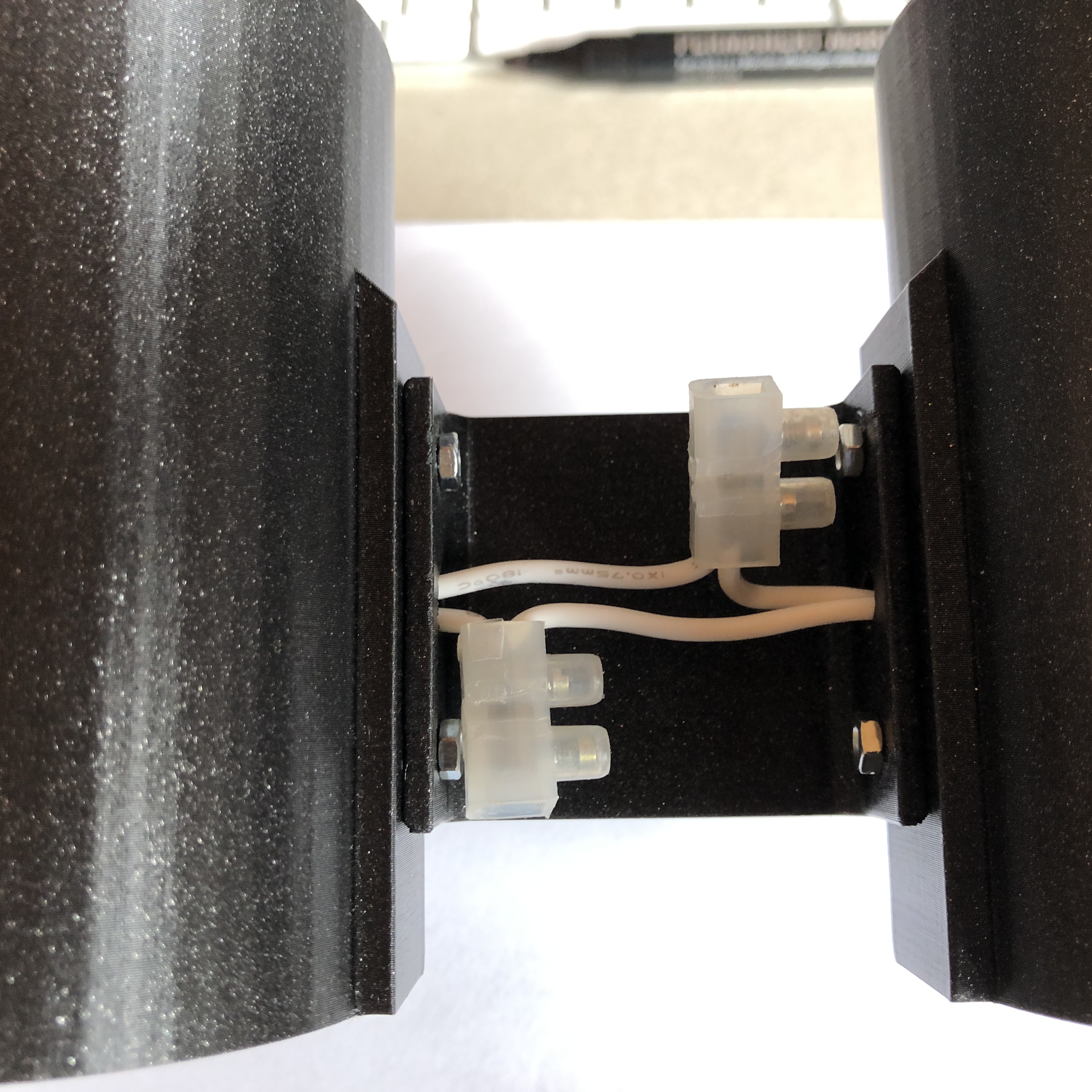

Now connect the cable ends of the two light sources with the help of the luster terminals as shown in the photo.

Step 7 - Installation Switch and AC/DC Socket

For the next step, you should have the following things ready:

"Lamp DuoLux_centralmounttop.stl"

AC/DC Socket 5.5/2.1mm

2 Position Mini Toggle Switch

switch wire, approx. 15cm (5cm black, 5 cm blue and 4cm black, for a better recognition when wiring)

1 self-tapping screw Ø 2.2x 2.9mm

soldering iron

solder

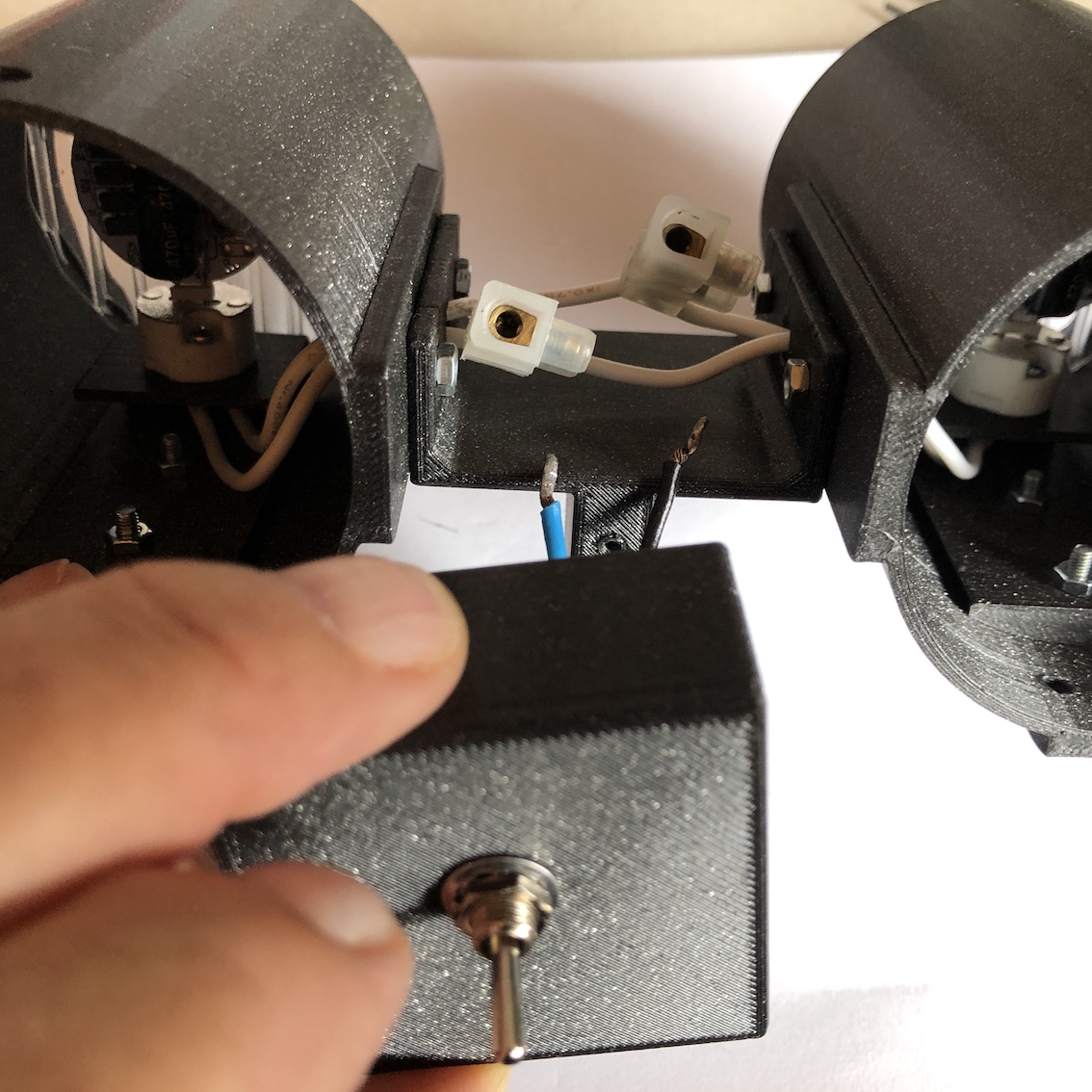

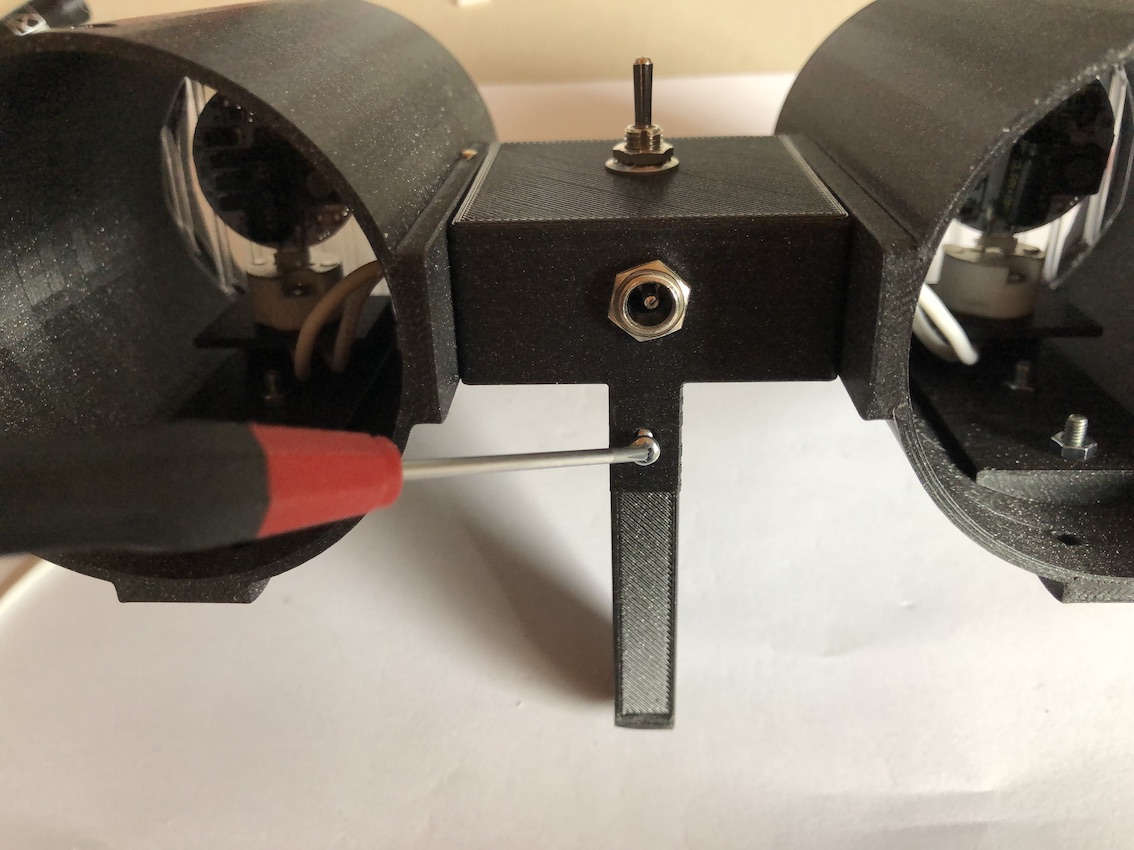

First insert switch and AC/DC socket into the holes provided in "Lamp DuoLux_centralmounttop.stl".

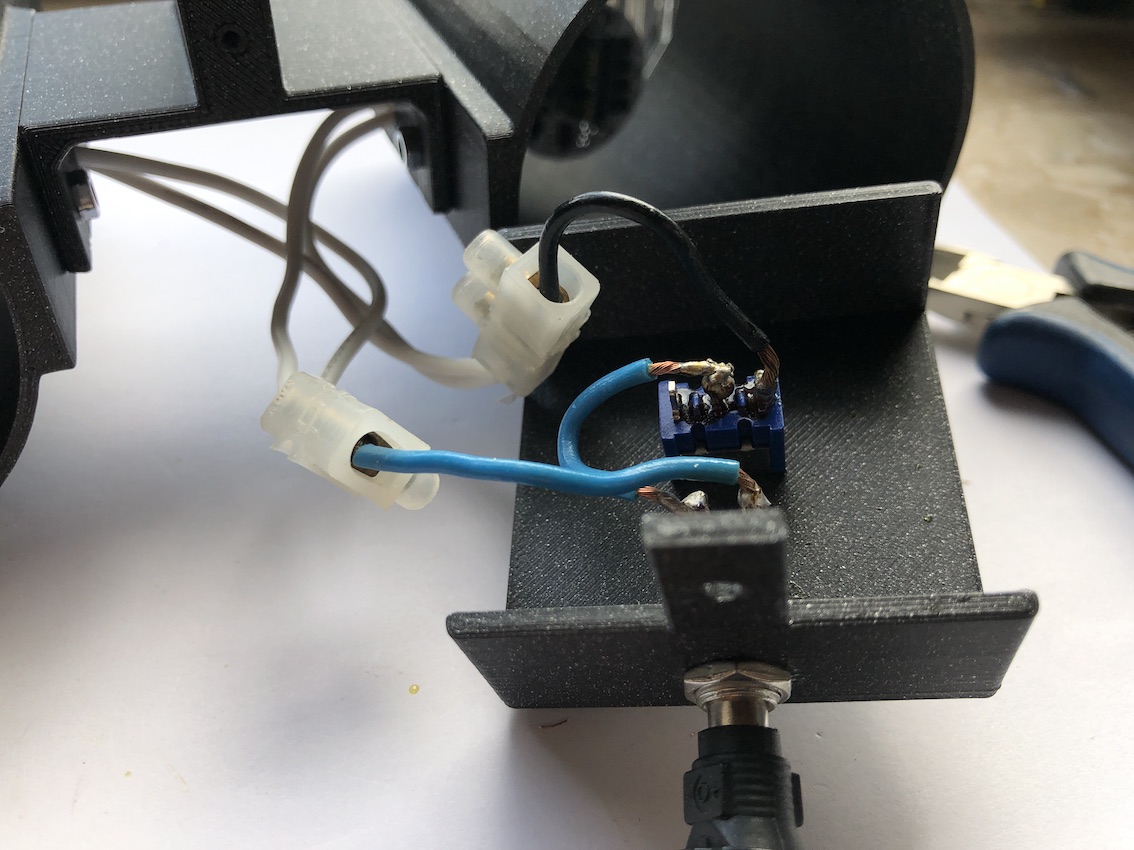

Then connect (solder) the blue wire from the luster terminal to the positive terminal of the AC/DC input. For easier handling, remove the wire from the luster terminal.

Then solder the black wire from the luster terminal to one of the outer terminals of the switch.

Now solder an approx. 4 cm long cable from the middle soldering lug of the switch to the negative pole of the AC/DC socket ... as shown in the pictures!

As the last step of the electrical work, screw "Lamp DuoLux_centralmounttop.stl" with a self-tapping screw (Ø 2.2x 2.9mm) to "Lamp DuoLux_centralmount.stl".

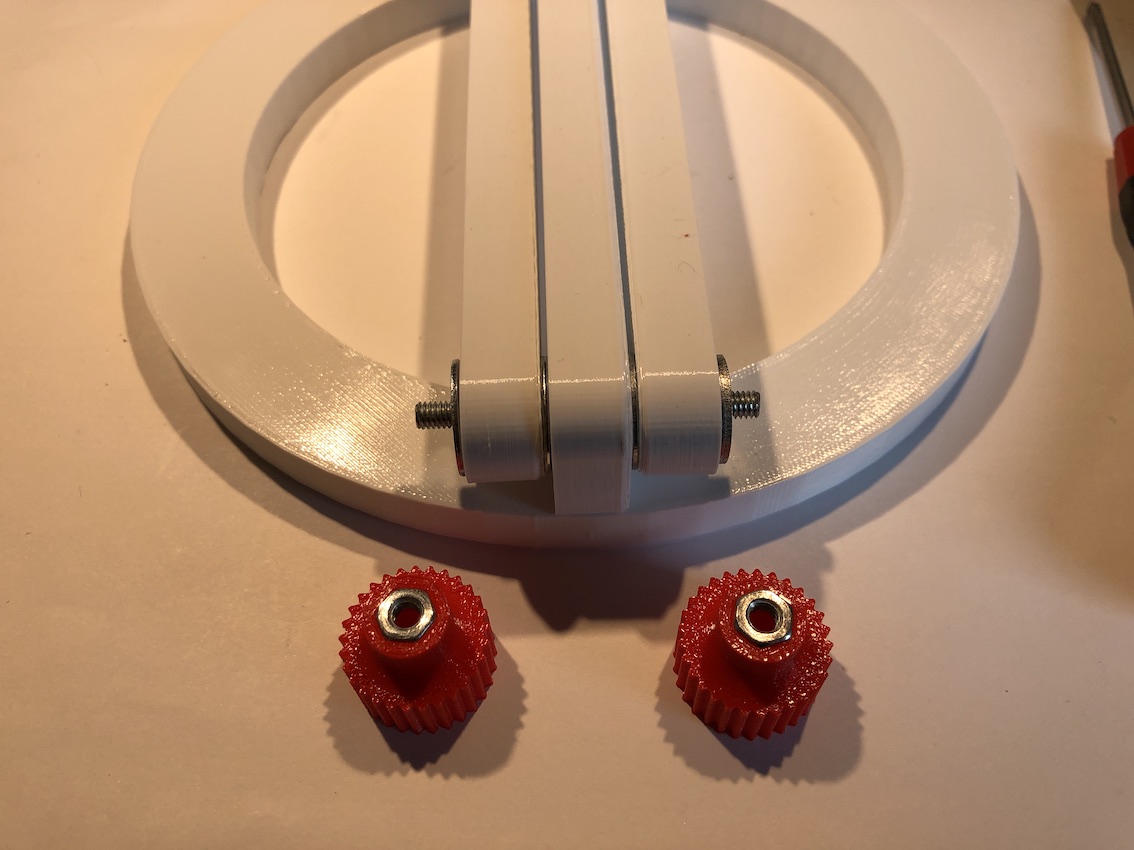

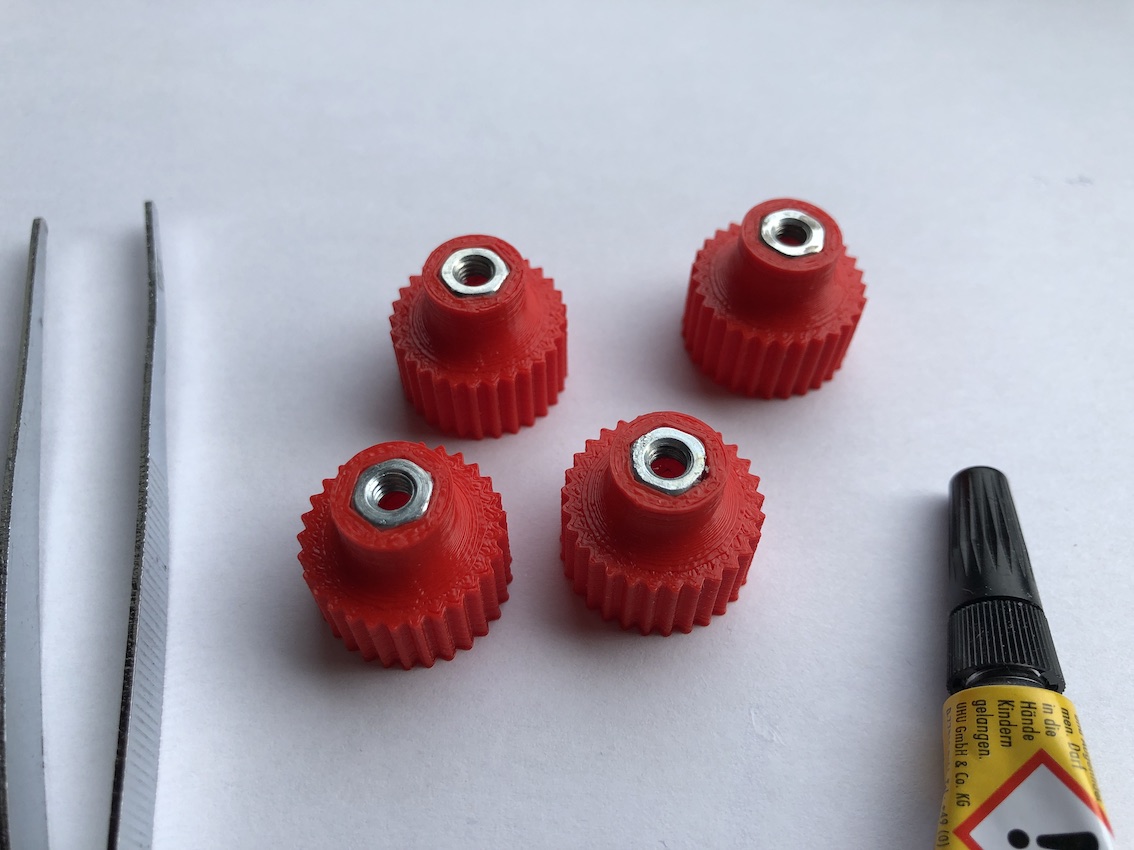

Step 8 - Prepare Fixing Knobs

For this step you need:

Add some superglue to the hexagonal recess and press the nut firmly into it. Knob back and nut should close flush.

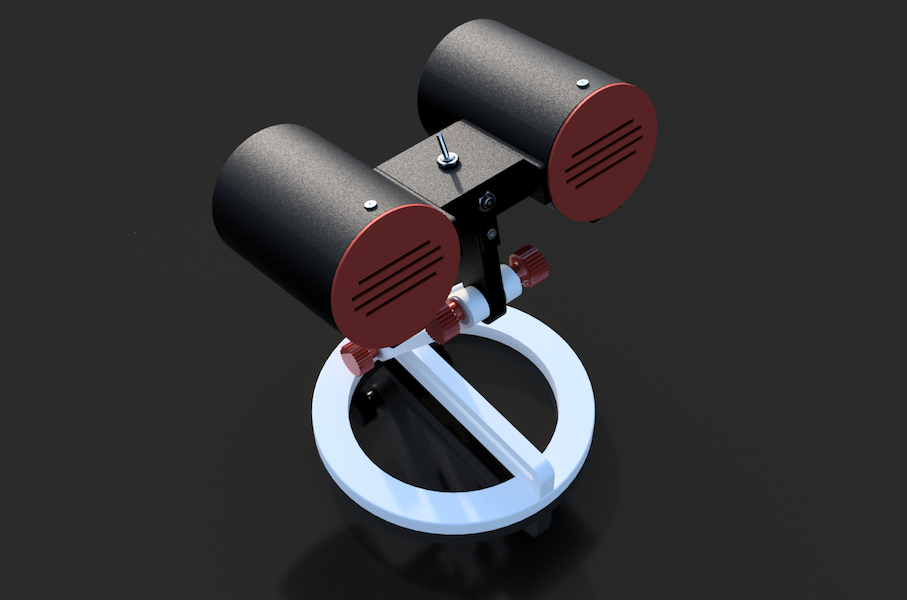

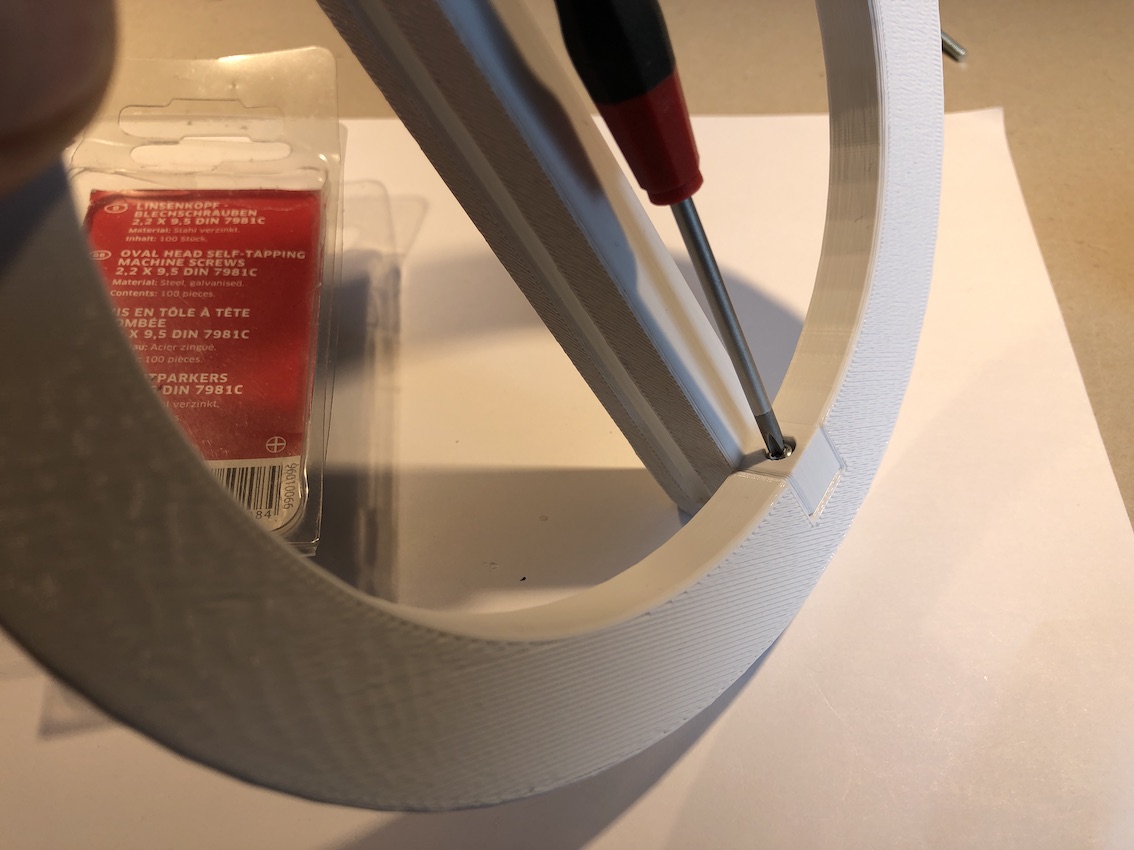

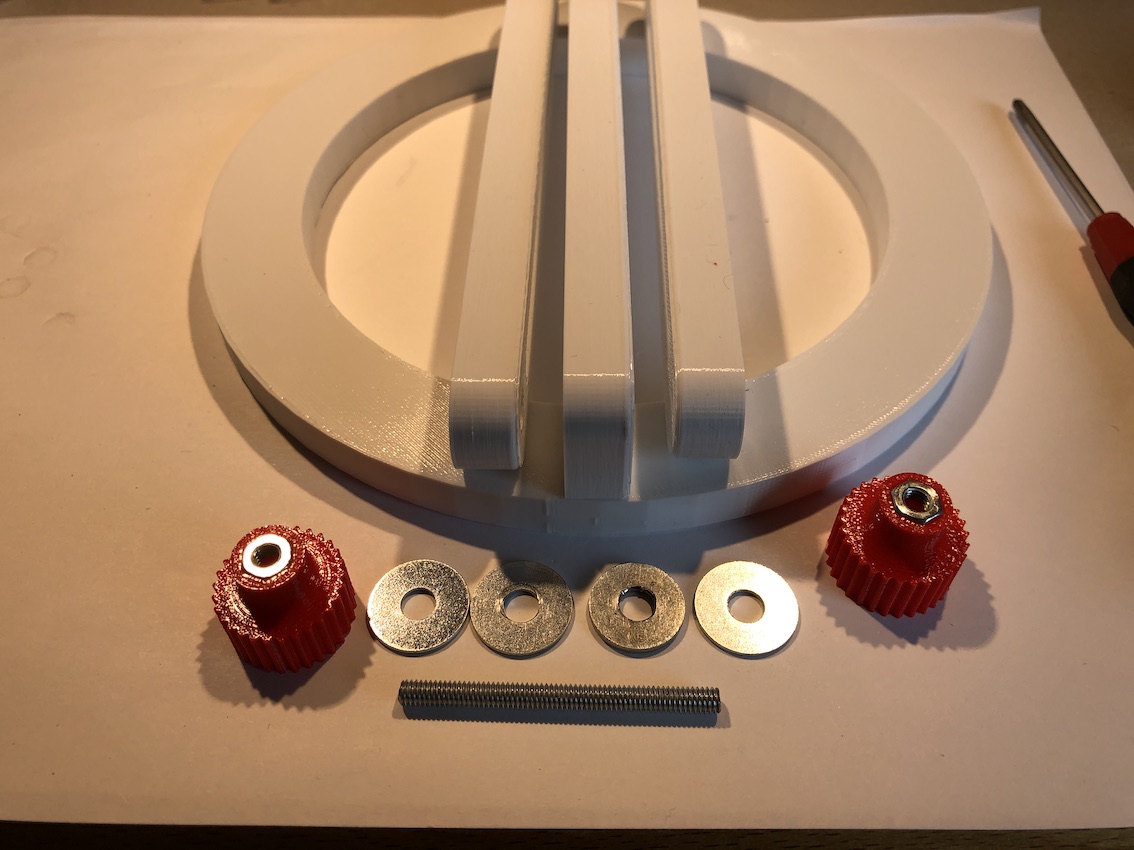

Step 9 - Assembly Base

For this step you kneed:

"Lamp DuoLux_basering.stl"

"Lamp DuoLux_sliderail.stl"

2x self-tapping screw Ø 2.2x 2.9mm

Phillips screwdriver

Place "Lamp DuoLux_sliderail.stl" in the recesses provided of "Lamp DuoLux_basering.stl". Fasten it on each side with a self-tapping screw.

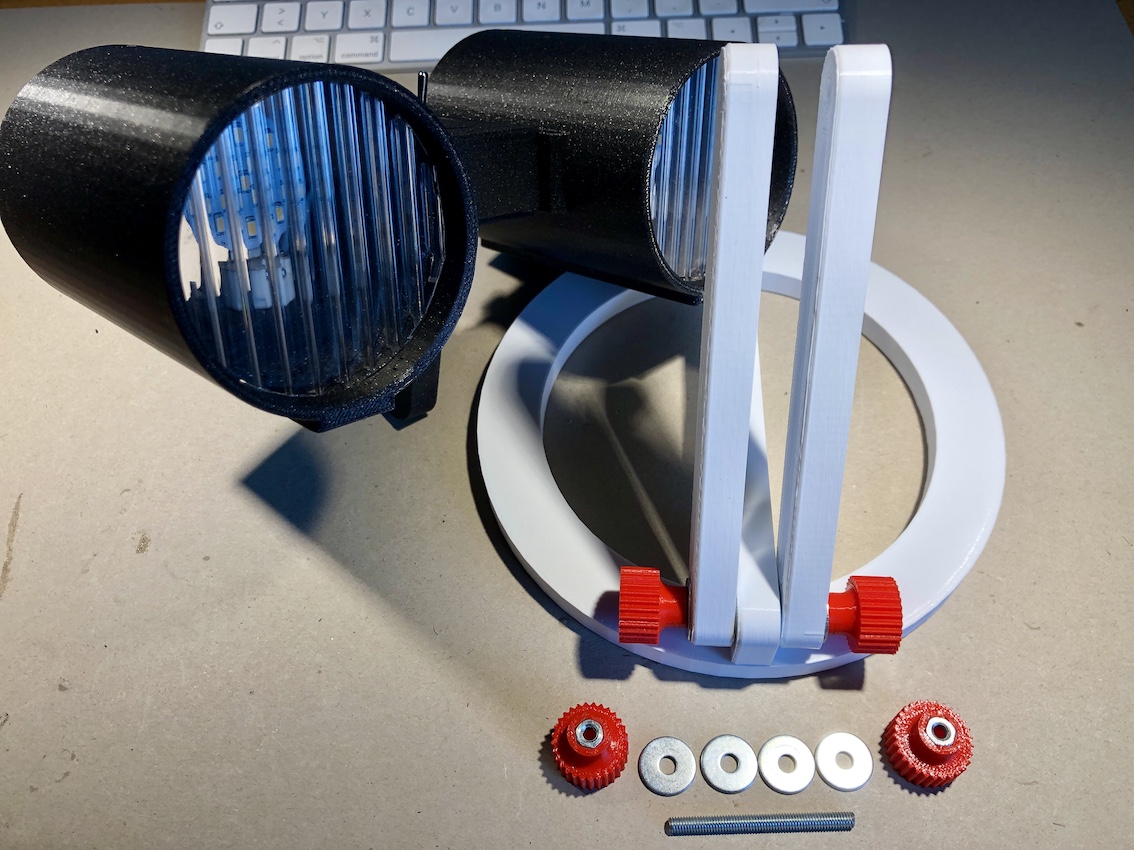

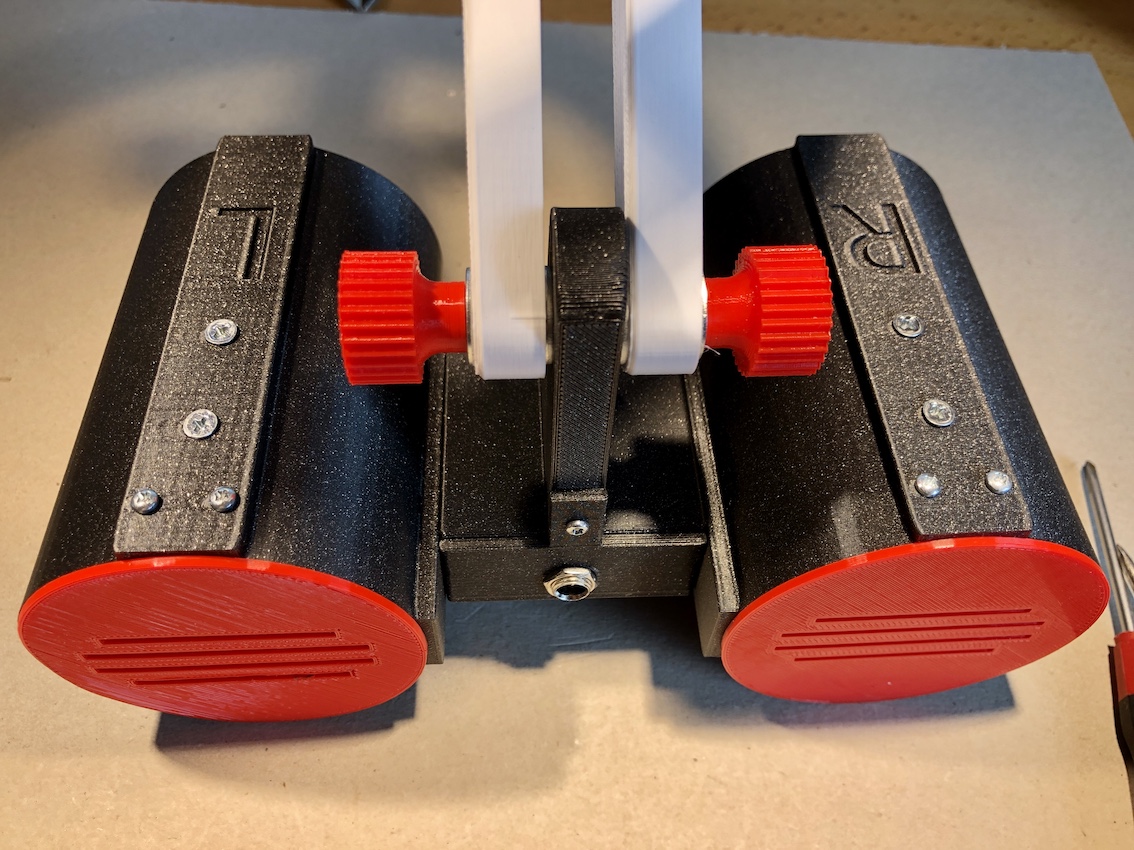

Step 10 - Assembly stand

Now you need:

Assembled base

"Lamp DuoLux_leg.stl" (2x)

2x assembled fixing knobs

Ø 4x45mm from a threaded rod (or screw Ø m4 x 50 and saw of the screw head)

4x washers Ø 15x4,5mm

Assemble the parts as shown in the pictures.

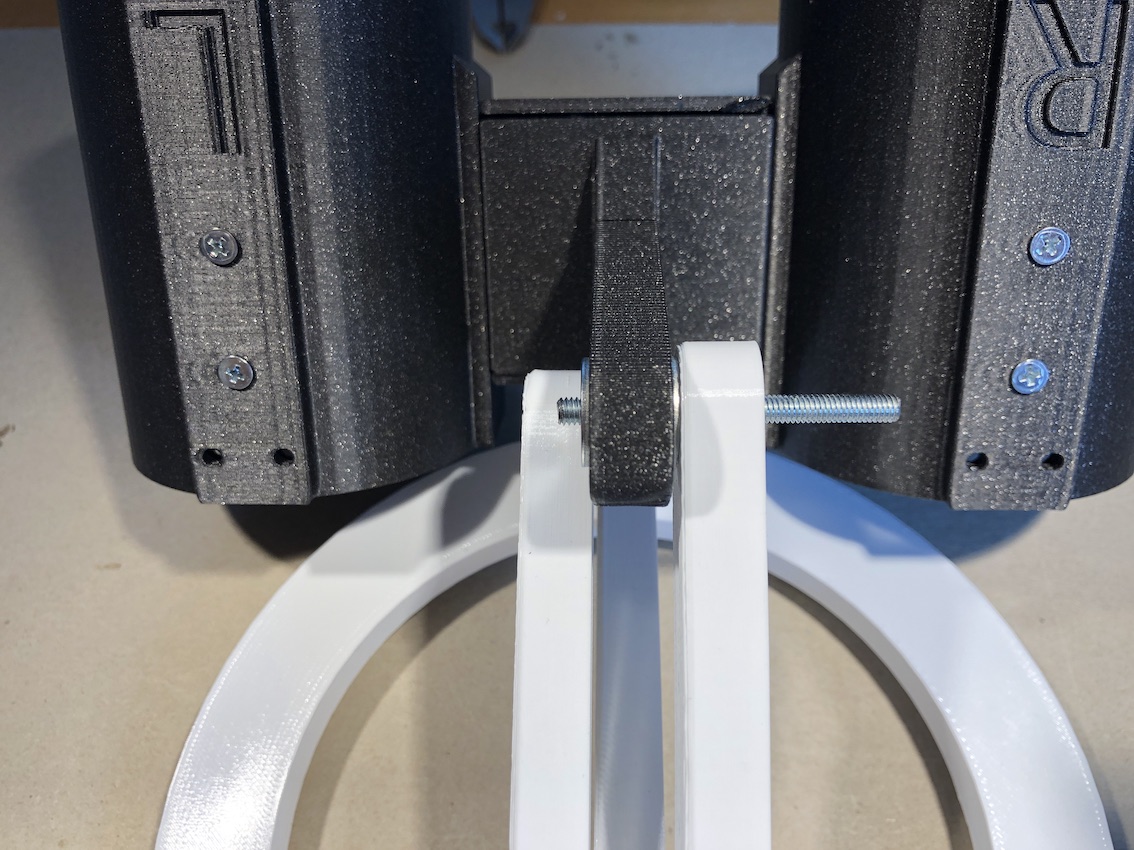

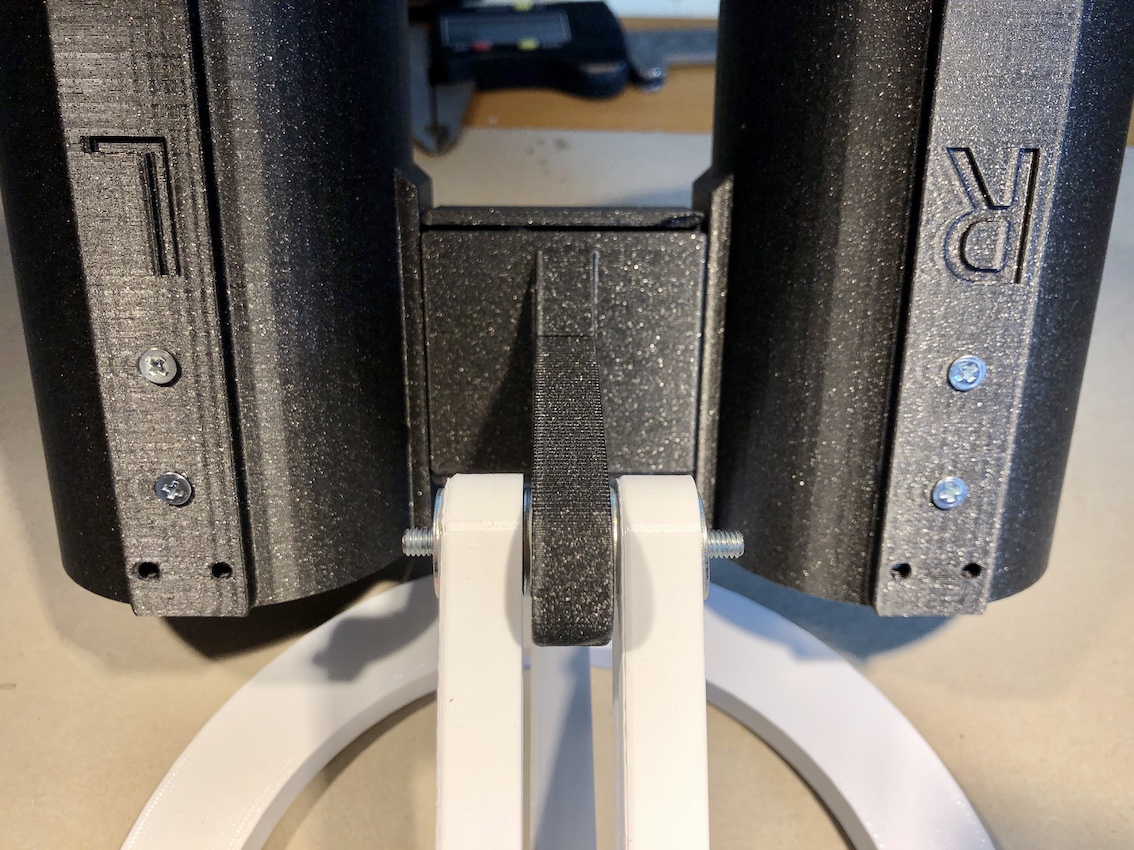

Step 11 - Assembly Lamp Head and Stand

For the second last step you need:

Assemble the parts as shown in the pictures.

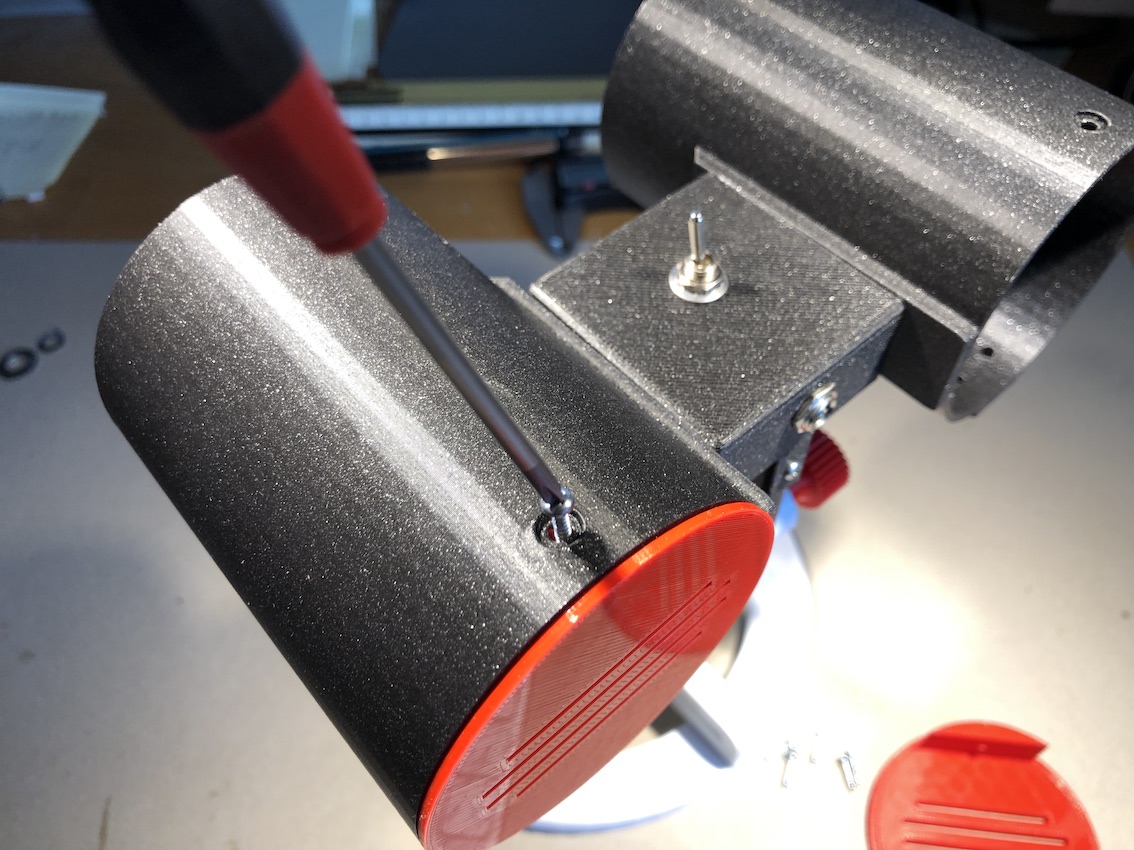

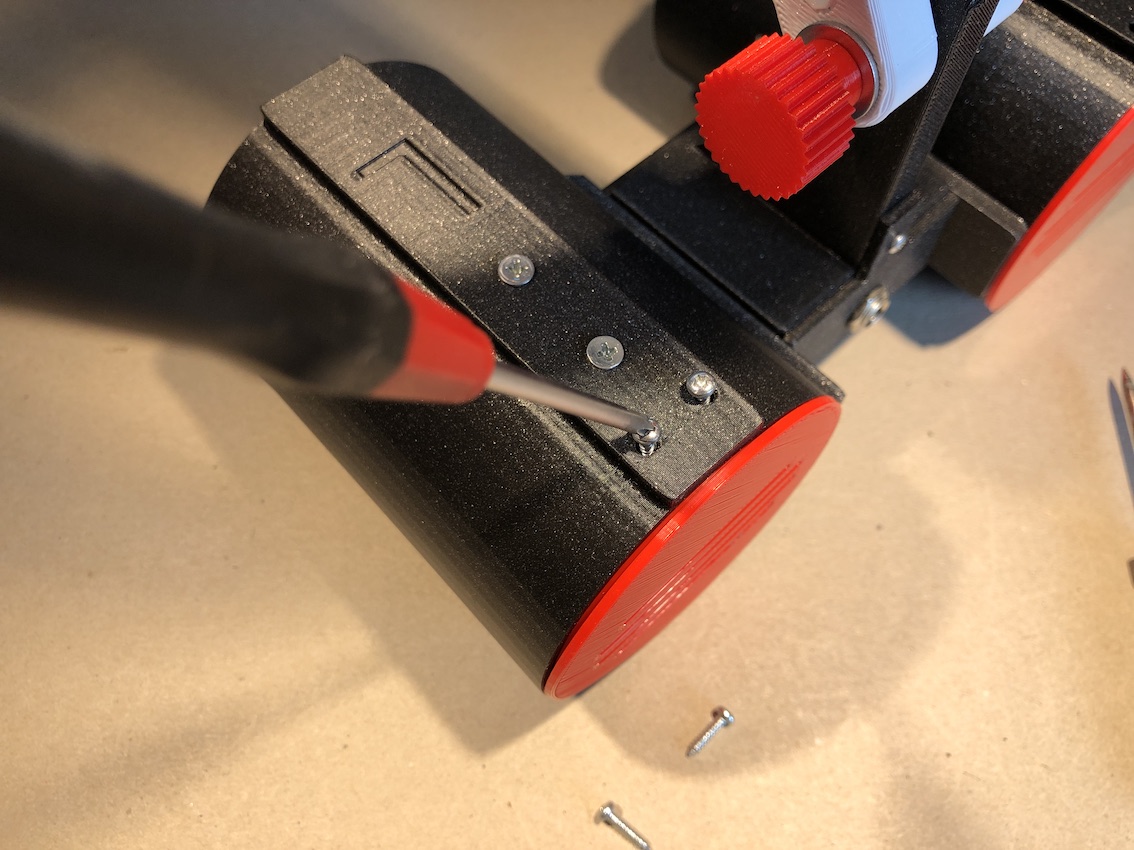

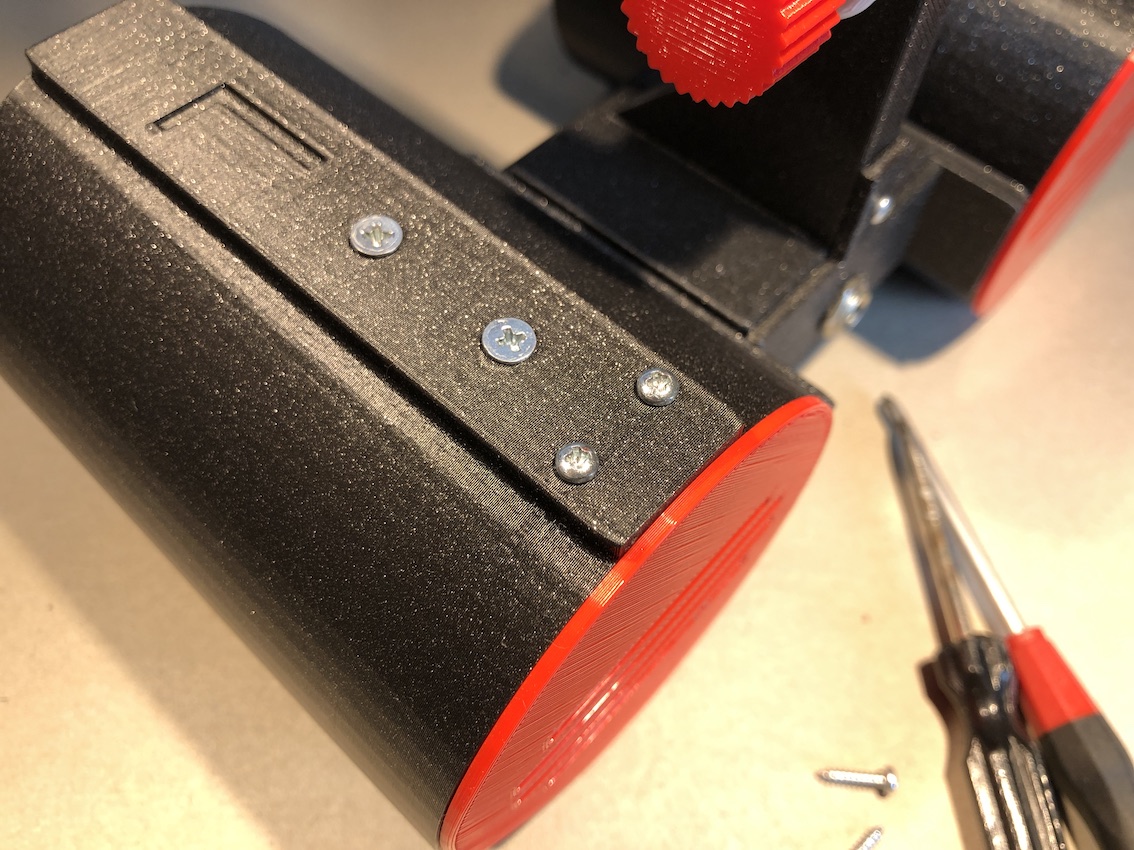

Step 12 - Attach Backsides ... Light On!

Now it's almost done! For the last step you need:

the almost finished lamp

2x "Lamp DuoLux_back.stl"

6x self-tapping screws Ø 2,2x 2,9mm

Phillips screwdriver

piercer

To make it easier to screw into the holes, I recommend to pierce the holes a little bit.

Screw the backs on as shown in the pictures!

Done!

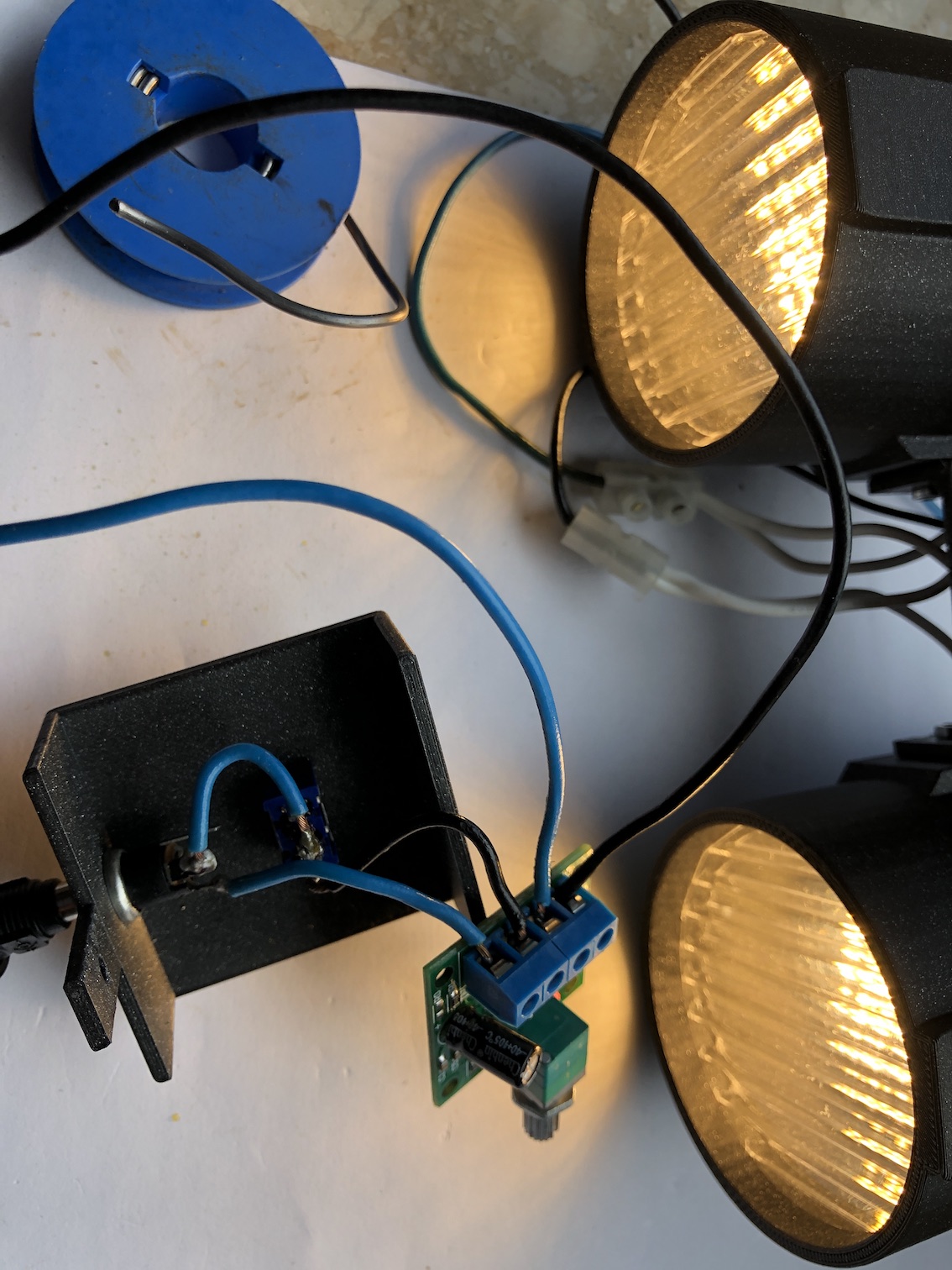

Now you can connect a 12 V AC/DC power adapter ... press the switch and there will be light!

If you have a power supply with variable voltage, you can also operate the lamp with 9V ... the light is then less bright.

Finally, note that you can align the leg forward, backward or at right angle straight up, depending on how you prefer it.

Have fun assembling ... I hope without problems!

Should there be one, please contact me!

/https://fbi.cults3d.com/uploaders/14974395/illustration-file/74f82239-41e3-4d1e-baa2-ae5da6a31827/Lamp-Duolux_14.png)