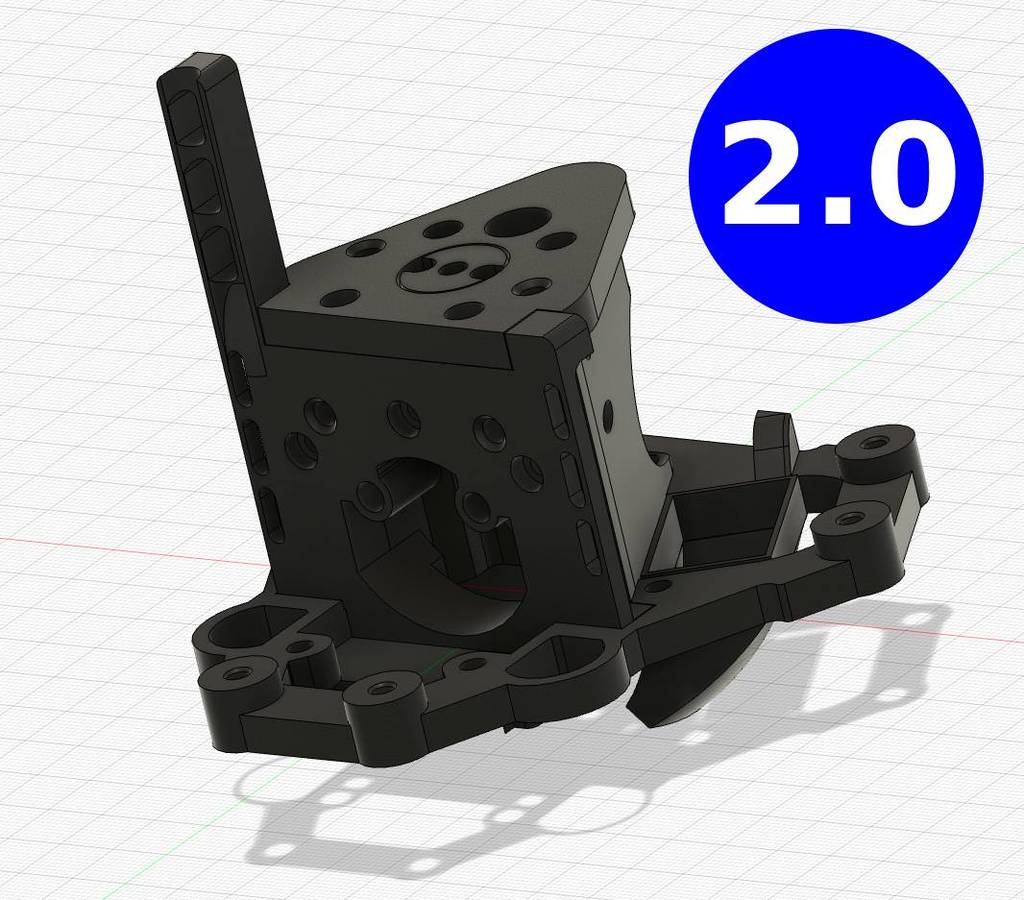

3D model description

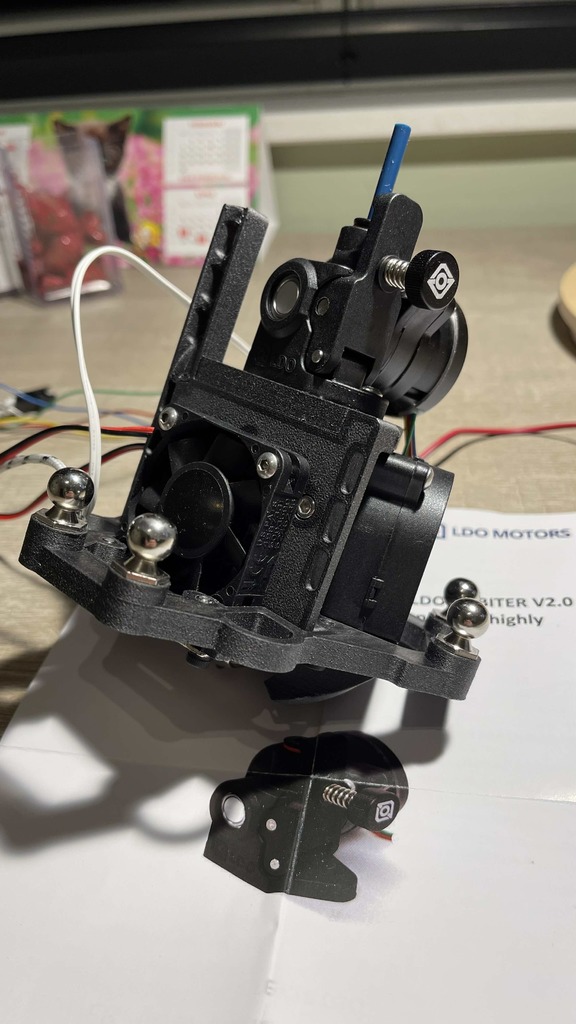

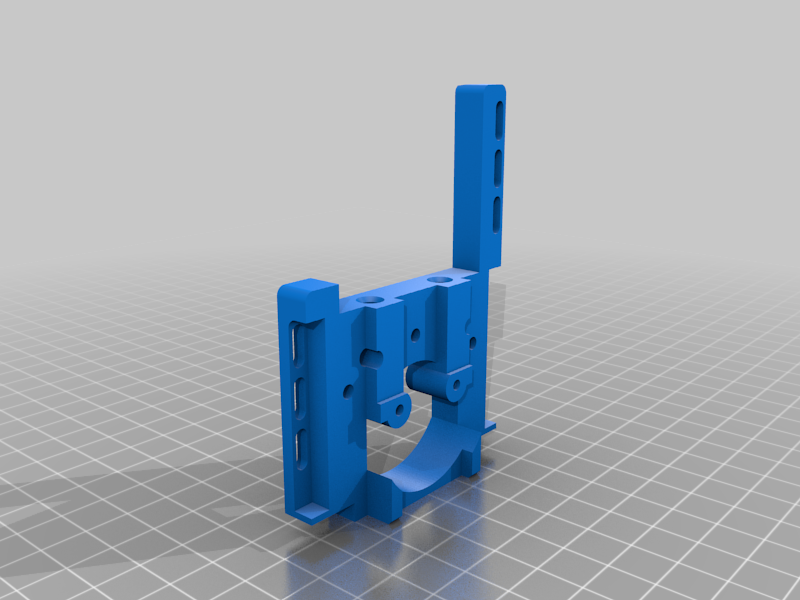

Based on my experiences with the earlier design (https://www.thingiverse.com/thing:4819243) using the Orbiter 1.5 and a number of minor anomalies I wanted to improve, I decided to make the move to the Orbiter 2.0. As changing the extruder required some redesign, I decided to just roll up my sleeves and change everything that I didn't like from the previous design while I was at it...

*** For Anycubic D 'Predator' Delta printer only. ***

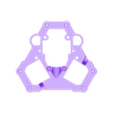

Designed for use with:

- MagBall arms

- Orbiter Extruder 2.0 (for 1.75mm filament)

- 2 x 4020 radial part cooling fans (WINSINN 24V dual ball bearing recommended)

- 1 x 4010 axial heatbreak fan (Sunon Maglev 24V recommended)

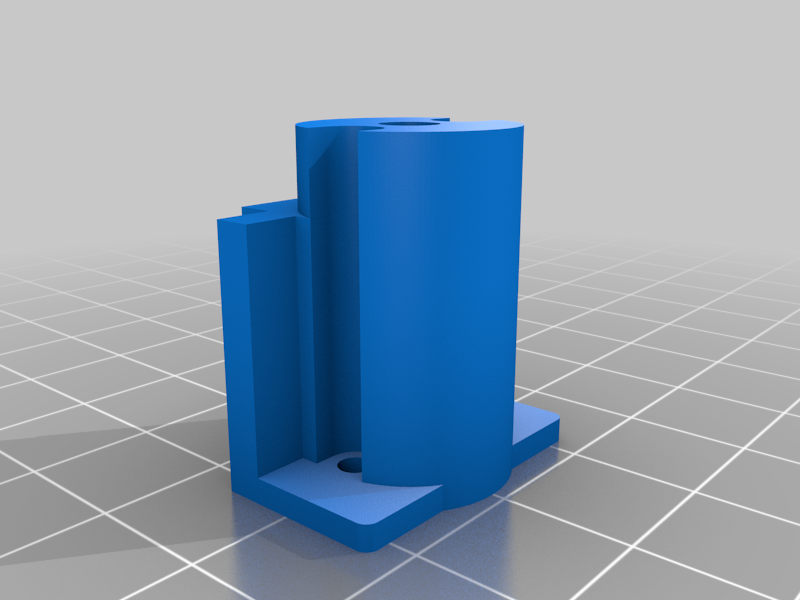

- Original Mosquito Magnum (or clone) - NOT the Magnum+

- Capricorn PTFE tube

- Threaded Brass Inserts (3mm thread)

Changes/improvements in comparison to the 1.5 design:

- Use of a (lower noise) 4010 heatsink fan instead of the loud 3010 fan

- Hotend Mount now has a longer left 'arm' to support the cabling upwards to prevent the cables to hang down and touch the print object at taller prints

- All screw holes are now designed to make use of 3mm threaded brass inserts for improved assembly / disassembly

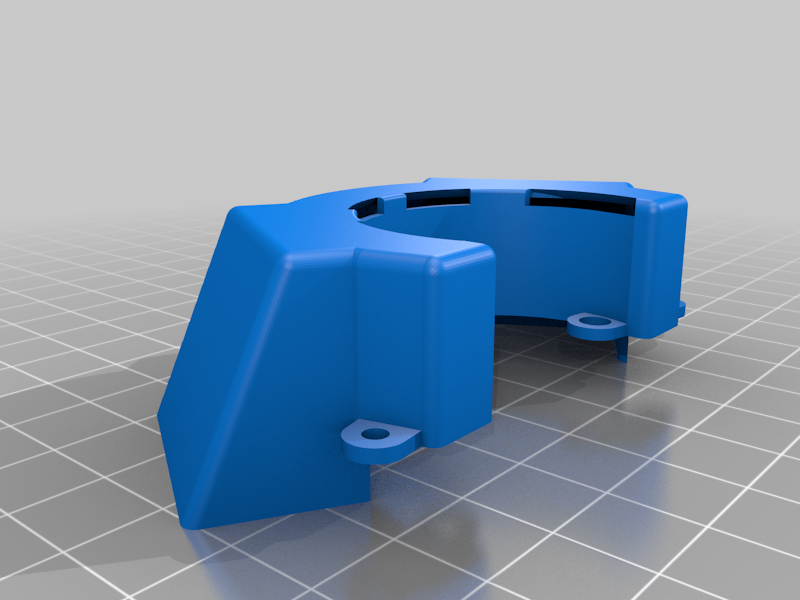

- The left and right 4020 fan mounts are now an integrated part of the base, leaving no room for movement or vibration and to provide a better airflow(out) for the heatsink fan

- Single-screw attachment for both 4020 fans

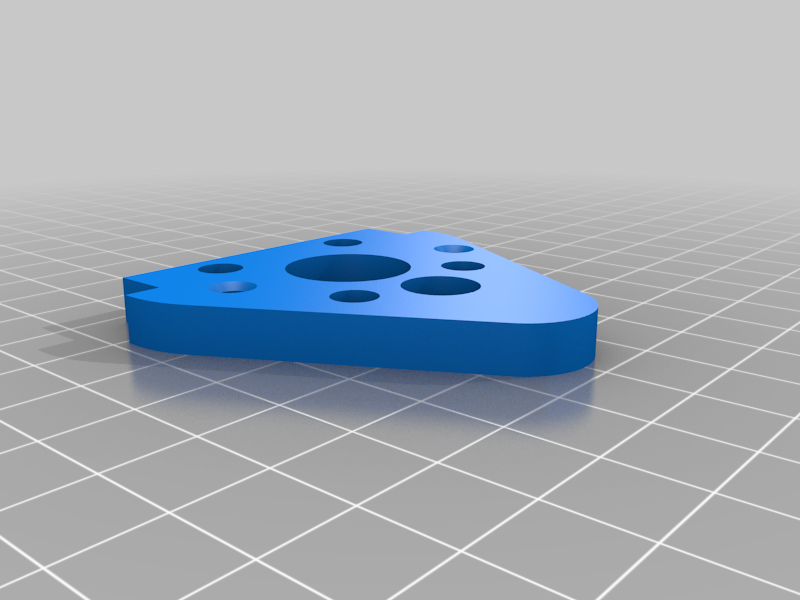

- Revised attachment system for the MagBalls with a M3 nut on the other side

- Newly designed fan duct that leaves more room for the hotend, connects better to the 4020 fans and (hopefully) provides a better airflow to the printed parts. But you can always choose your own preferred duct or use the Sakman 4020 fan duct. Link: https://www.thingiverse.com/thing:3585762 (his V1 version is included in the Download files: Fan_Duct_Original_V1.stl).

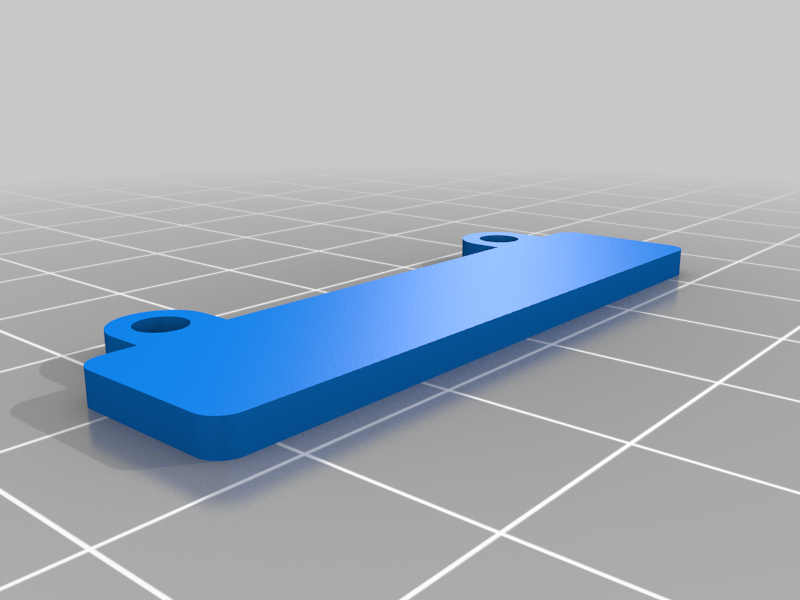

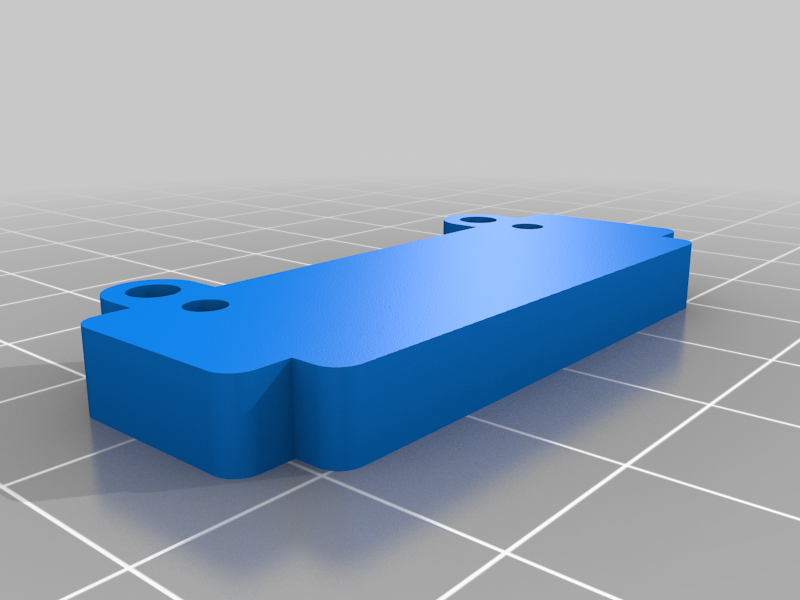

- You can use the original 'magnetic' steel plate for the Bed Level Probe sensor but you need to print the included 'Probe distancer 2mm.stl' for the correct height.

IMPORTANT INFO about using the original Anycubic PROBE:

OPTION 1: If you are using a clone Mosquito Hotend like the NF Crazy that has a very forward protruding hotend shape, you need to use the Probe_Distancer_2mm_NF_Crazy.stl to stay clear of the hotend. BUT: Since the Probe center is now positioned minus 5mm more to the front of the machine than the center of the nozzle, it will not be able to calculate the correct UBL/ABL Bed Level data since you're always 5mm off. To compensate for this (in Marlin) you need to adjust your Probe Y Offset value to -5.00 mm. Do this before performing any levelling as otherwise your probe will pop off the frontside of the bed.

OPTION 2: If you use the original slice Engineering Mosquito (Magnum) hotend, you should print and use the Probe_Distancer_5mm_Mosquitostl. This will put the steel plate on the original position and you don't need to adjust the Probe Y Offset settings (just use 0.0) and stay as 'vanilla' as possible. It's a bit thicker (+3mm) to allow you to screw the steel plate on to the Probe Distancer. Use short screws so they don't touch your 4010 fan.

PTFE tube length to cut: total 34mm (have tube sticking 6mm out of the Groove Mount Adapter)

Never used threaded brass inserts before? Then this is a good read: https://hackaday.com/2019/02/28/threading-3d-printed-parts-how-to-use-heat-set-inserts/

** TIP OF THE DAY: get those special 'threaded inserts tips' for your soldering iron so you don't accidentally deform the upper brass thread while inserting and render your thread useless. You can easily find them cheap on Amazon or anywhere else for that matter.

Again: kudos to Graham Ham who inspired me for the base design and Róbert Lőrincz for the magnificent Orbiter Extruder!

GHCP (Graham Ham): https://www.hamrx8.com/index.php

Orbiter projects (Róbert Lőrincz): https://orbiterprojects.com/

/https://fbi.cults3d.com/uploaders/15126252/illustration-file/36c643f3-043b-4d70-a4fa-985aebb9eaf6/Intro_CAD.jpg)