xyzprinting table for use of MK2B or MK3 heat beds and glass

214x214 and 220x220

this was by request as i did not realy nead to upgrade i have plenty of new replacement

heat beds for the printer and i showed you how to use both sides of the glass in a

previous upload

but when you go and try to find just a piece of 211x211 glass for the xyz printer

absolutly nobody sells this size glass so this is when to upgrade to standard size bed

you can also remove the heat element from your xyzprinting bed and put a piece of paper on

the top like i show you in my previous instructions to use both sides of the xyz printing

glass and just purchase the standard size glass bed and use your old heat element

there are 2 sizes i made the first table for 214x214 and purchased a 214x214 aluminum heat

bed but was sent a 220x220 heat bed so i had to order another 214x214 heat bed to check

fit

to make sure you get the right 214x214 bed is make sure it has MK2B in the title even

thought it says MK3 214x214 chances are they will send the wrong bed but don't freet the

220x220 bed will work in the xyzprinter this is probaby the max size that will fit but it

will work

you can use either the aluminum plate or purchase a seperate heat element and glass

these are the same instructions for both 214x214 and 220x220

this was also made to acomadate a 2mm piece of cardboard for the bottom heat shield under

the heat bed

these are the back side of the bed

print bottom side bottom left

print bottom side bottom right

working with acitone i find that a brush works realy well i also have a 3d smoothing pen

you fill it with acitone and use it to smooth ABS prints that works realy good for this as

well

glue using acitone this is the back side of the bed where the wires are on the heat bed

you will see the 2 indentations for the wires

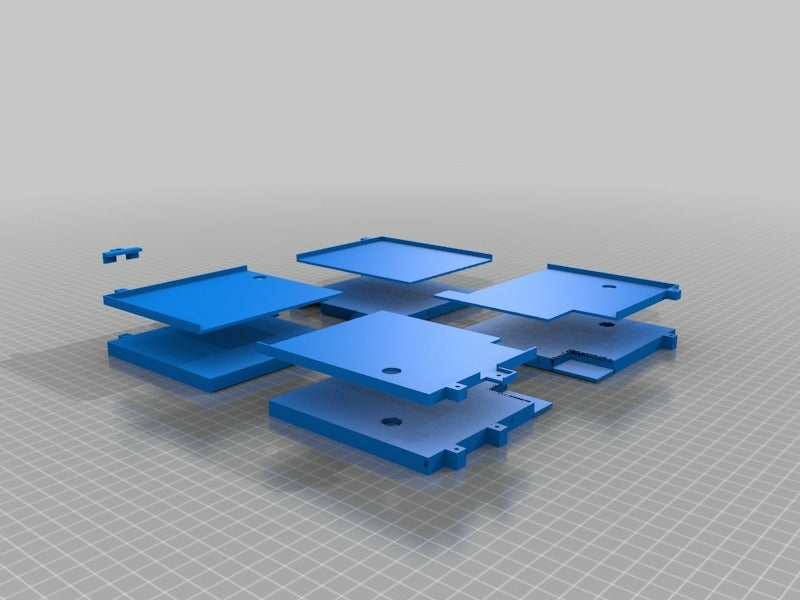

these are the front side of the bed

print bottom side top left

print bottom side top right

where the center screw hole is there is a indentation that fits the 2 pieces together

next glue the 2 parts together using acitone

now you are looking at this thing on the top this is where the confusion in naming is the

names are to match the top with the bottom but now you are looking at it from a differant

view of how i created it from bottom to top left is now right and right is now left bottom

is now back and top is now front

print top side bottom left atach using acitone to the top back right corner you will see

the extra tab this is for the xyz printing thermaster

print top side bottom right atach to the back left corner lineing up the hold down screw

tab and the cutt out for the wires

print top side top left atach to the front right corner lineing up the adjuster screw hole

on the top

and fianly print the top side top right and atatch to the final space front left corner

print 7 glass bolt downs

drill all the holes with a 2.5mm drill bit

on the bed there is a hole in the center this is where the thermaster would normaly go we

are not using this so tap with a 3mm tap and put a screw in with lock tite and grind flush

the bed i have found that nothing and i mean nothing sticks to this stuped thing all your

old methods of making plastic stick to the bed like elmers purple, hair spray,ect ect are

now usless methods so back to the beginning with thinking

what i had to do with the 220x220 is i had to take realy rough sand paper about 80 grit

this thing is hardend aluminum and rough up the surface then put a coat of polyurathane

when sanding only go left and right then top to bottom do not use circular pattern

let it air cool then heat the bed up to temp and let cool this will cure the surface if

you do not do this you will constantly be reaplying

this method is a permanent sticking solution and no nead to use anything on top of this

if you get any pealing just take a paint brush and fill the open spots

i do not know how long this method is good for but it is probably about the same time as a

build teck top which trust me does not last as long as you think it should for the price

next is optional but highly recomended

now pat yourself on the back and go have a beer and take a break consult a therapest as to

what was going through your head and why you got into 3d printers in the first place

??????

/https://fbi.cults3d.com/uploaders/16777860/illustration-file/1ffccc7e-940c-43a2-af48-dce82884da0d/DSCN0485.JPG)