Fan of unusual thnigs, this is my version of Gooseneck trailer. Inspired by US manufacturer pictures and drawings we can find on internet. It is actually design to suit the FMS ATLAS 6x6 following Derek request.

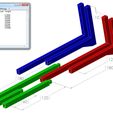

The version in pictures is 540mm payload area (flat area) with additional rear ramp. 3 section of 180mm are needed, then I cutted in different pieces with male and female connectors to let you compose your own trailer. You can see in picture the different sections. there are even 10 mm higher L frame versions in case you want to use this trailer on a car with higher bed. Ball joint female is adjustable and the Pipe in which the ball joint is going can easily beeing printed longer with upscale on Z.

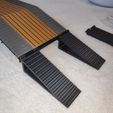

two versions of the rear ramps are available,

one is a 180° flipable one which let a nice flat effect on the ramp in transport position

one is a flat ramp you can let vertical or even a bit on the rear for transport position. 2 brackets have then to be fitted on the ramps and trailer. Holes are already there, just use M1.4mm screws. One eye of the bracket should be cut with a cutter to get a hook form.

For this version of ramp you need to fit the rear stabs under the main frame. Tight the screws and it will stay in place.

Rampe hinge need a 2mm rod, lenght corresponding to the trailer width, 120mm.Take care when glueing the 3 fix sections on the ramp upper structure. It must be glued with the rod inside all parts to be straight and easily manoeuvrable. No special issue there, just be cautious. Check the flipable ramps are aligned with the trailer in transport position. Key point to have something nice.

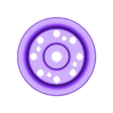

Two versions of wheels are available with same payload plate level from the ground.

One for 35mm wheels, with bigger articulation

One for 45mm wheels with more all terrain look.

Either you print the rims included in the files set or you use any wheel you find on toys with 3mm holes in the center.

In cas you use the included rims, I gove you below reference of the tires I used in pictures.

please notice that the 2 brackets on which the leaf springs are articulated (4 half brackets) can slide on the A frame. Normaly if you tighten the screws it stay in place . If not just add a piece of adhesive paper to reduce the gap. It is good to have it sliding to adjust position of the wheels along the frame and then adjust the weight on the ball joint to get full shocks movement. If you don't care, choose the best look position and glue.or screw.

The upper parts are 60mm long, you have one structure part, two side panels and one central panel which try to simulate wood plates. Depending of the lenght you choose you have to print several set of those 4 parts.

When assembling the 2 full L frames please take car to make it straight and equal. General geometry is depending of that glueing. Same when you add the ramp parts at the end of the L frame.

In case you don't want to use the ramp, you have a cap to print and cover the female connector of the L frame.

You have a side light you can duplicate all around and a 3 modules rear lamps, see pictures.

There are reinforcement plates for the leaf springs ends which have to be glued on the leaf springs before assembly on the axle. It prevent of breakage of the leaf spring end area when you tighten the screws.

Flat bed plus ball to allow hauling is in other set of files.

Depending of the holes you will find, you need some M1.4, M2, M2,5 and M3 screws.

Wheels to axle : M3

leafspring to axle : M1.4

Leaf spring brackets assembly : M2

Leaf spring to bracket : M2

end of stab leg : M2.5

Female ball joint adjustment M2.5

flat ramp bracket on ramp and on trailer : M1.4

stab legs on brackets : M2

Rims assembly : M1.4

Tyres 45mm : 13616 Tire For RGT 136240 V2 1/24

Tyres 35mm :Wltoys 1/24 RC ref A242-01

https://www.ebay.fr/itm/4pcs-13616-RC-Car-Tire-For-RGT-136240-V2-1-24-2-4G-Vehicle-RC-Rock-Crawler-Parts/184566408417

https://www.ebay.fr/itm/Wltoys-1-24-RC-Car-A242-Spare-Parts-4Pcs-Tires-A242-01/172428879402?ssPageName=STRK%3AMEBIDX%3AIT

2mm rod: https://www.ebay.fr/itm/2Pcs-Stainless-Steel-Shaft-Round-Rod-300mmx2mm-for-DIY-Toy-RC-Car-Model-Part/392267264913

https://youtu.be/stEkEorkHKg

3D printing settings

Noting special

some parts need supports, set support size to 1.2mm specialy for rims.

Print smal parts, ball joint parts, leaf spring at low speed.

big parts were printed here at 50mm/s on a creality CR10

/https://fbi.cults3d.com/uploaders/13410598/illustration-file/7fc97ccd-2451-4bfd-bb9c-cc917fe4e246/IMG_20210430_165951.jpg)