Update 23. November 2014:

I extended the bottom angled part of the front skids. No matter how I tried to print them, they always ended up curling and producing an extremely ugly angled edge when using ABS. Should be much cleaner to print now, but there'll still be minor curling at the back of the two rails inside. Cut with a skalpel.

Update 21. November 2014:

Finally had a chance to do a proper maiden flight and film it.

http://youtu.be/CelgFdRE9Kc

Update 19. November 2014:

Modified the buzzer plug hole position some to fit the plug better.

Update 16. November 2014:

- I modified the landing skids a little to include slots for 2.5mm wide zip ties, to avoid them having a chance to slip off. Print as-is, with support and overhang angle at 30°.

- I also updated the tail. The nut trap was still too large for my taste, introducing quite some play and also allowing the nut to turn when trying to tighten it down. The new nut trap is properly sized for M3 nuts, but can be a bit tight. My slicer added support inside the hole, I had to clear some bits with a sharp knife. If you have trouble getting the nut to fit, stick a long M3 screw in from the back of the tail, screw it a few turns into the nut, then pull the nut into the opening firmly.

- Modified the canopy. Shorter at the rear, reduced the hole at the back. Slightly increased width of the ziptie slots to reduce rubbing.

I made some modifications to this awesome design by Boxx to better suit my setup.

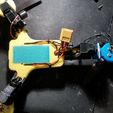

The inside space was widened and standoffs were put in place so a KK Mini board (30.5x30.5mm mounting points) could be installed. I used metal screws to thread the holes, then used nylon screws to fix the KK in place. Since I had no 3mm nylon screws, I used 8mm ones and cut them off at the bottom.

The motor mounts were modified to allow me to mount motors with a flat bottom and 2x12+2x16mm motor mounting holes for M2 screws, such as the DYS BE1806 motors. You can still use 4x12mm motors, just with 2 screws instead.. that is still plenty of support. Use washers.

A 3mm hole was added to the front to allow the installation of a 3mm LED. In my print, it fits snugly with a little push, but you may have to add a drop of hotglue to keep it in place. You can grab 5V for the LED (with a proper resistor) from the ISP port at the front of the KK board for a little less wiring mess.

I added a hole for the buzzer plug, but I have no idea if it fits.. I have my buzzer directly soldered to the board. If anyone tests this, let me know please. I uploaded both versions with and without the buzzer plug hole.

The tail was changed to open up one side to allow the installation of the motor without having to desolder the wires and lead them through the hole. Also, with the 1806, this was a tight fit in the first place due to the thicker wires they use. I modified the nut trap a bit, as it was so wide that the nyloc nut started spinning when trying to tighten the tail bolt. Lastly, the tail was modified to be laid flat on the bed, allowing for cleaner printing of the bottom and top and without needing any support.

The canopy had to be redesigned. Admittedly, this is a bit of a hack job.. I've never used any CAD-like software before and this is the best that I could do. It has two slots for zipties that will at the same time secure the ESC power wires of the two front ESCs if mounted as intended.

I wired the servo and ESCs to lower profile pinheader sockets to reduce the required height as much as possible. However, I still use a full size servo plug for the OrangeRX satellite, so I assume the canopy will fit with standard plugs too.

There is a theoretical space for a 3x7x3 bearing on both sides of the tail. The inner one was already there in the original, but ended up being a little too small on my print. The one on the outside is just meant to give the bearing some hold. If they are tight, try adding metal washers on either side.

If you find any problems, let me know and I can try to fix them.

/https://fbi.cults3d.com/uploaders/18411402/illustration-file/8f38d10d-b864-474d-98c5-cb82fb169486/MK5-1806-LED.png)