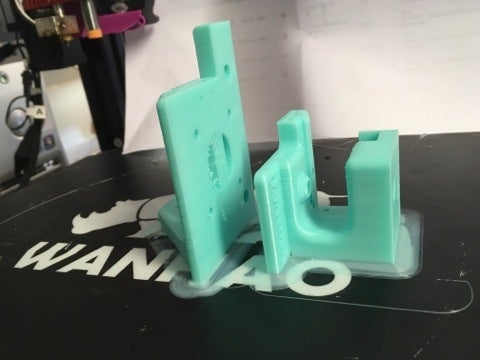

This set of two brackets is an upgrade for the Wanhao D9 / Monoprice Maker Pro

BOTH ITEMS PRINT WITH THE RECTANGULAR HOLE DOWN ON THE BED

What this does

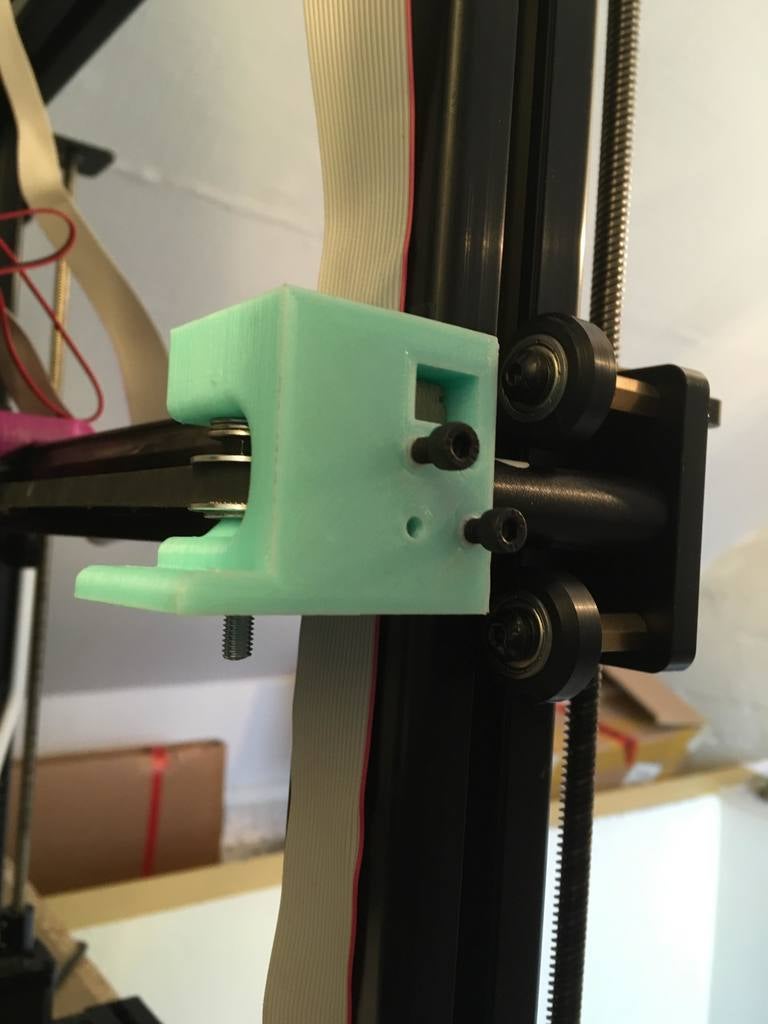

1 - Provides a way to tension the X axis belt - screw in 4x M4 bolts

Note, you don't have to screw them in BOTH sides, just whichever side is easier for you to access on your printer!

2 - Significantly stiffens the Right hand idler mount - the standard plastic bracket mounting underneath the 20x20 extrusion isn't enough, it makes the idler lean to one side. This bracket supports from the TOP and the BOTTOM.

3 - Significantly stiffens the LEFT hand side stepper motor mount - the standard plastic one flexes a tiny amount when printing - not badly admittedly but this bracket is much stronger

4 - Corrects the Belt geometry - the factory standard setup has the centre of the stepper motor not properly aligned with the center of the idler on the right hand side. as a result, the belt ends up further away from the carriage on one side than the other. The stock is only a few millimeters out, but every small part helps!

5 - Assists with levelling the X axis gantry. There's now two tabs, one on each side, the underside of each is at exactly the same height. Now you can simply level your printer by jamming something between the bracket and the 40x40 below, then lowering the gantry.. repeat on the other side and you're level! - see pics for an example using my calipers.

6 - Lowers slightly the left hand side limit switch to avoid it rubbing on the bottom of the drive belt like the stock setup has.

7 - Adds another BLEUGH branded item to your printer :-)

V7 - small tweaks

added notches at the holes for the T-Nuts to sit in the 2020 extrusion better. This should give a more secure fitment for all T-Nut types

Changed the mounting depth of the holes for the 2020 extrusion bolts. Should work fine with the stock bolts now, the V6 one needed 10mm on some machines, M12 (stock) should be fine now

Changed the width of the built in supports for the stepper mounting circle from 0.3mm to 0.5mm. Now Cura will pick up the supports even if it's setup to the default 0.4mm line width

V6 - Numerous edits

*Limit switch mount lowered by 1mm to avoid the screws rubbing the belt, this corrects a problem with the standard Wanhao setup

*The 4 x Tensioning screw holes on each side are now 3.8mm / M4 and will self tap nicely without removing so much material (some were concerned that the 3.5mm holes were a little too small)

*Reduced the 'standard' distance between the centres of the stepper motor drive and the idler by 2mm to allow more flexibility with different belt lengths on the wanhao stock machines

*Fixed the right hand idler bracket extrusion part that wasn't cutout properly (oops!)

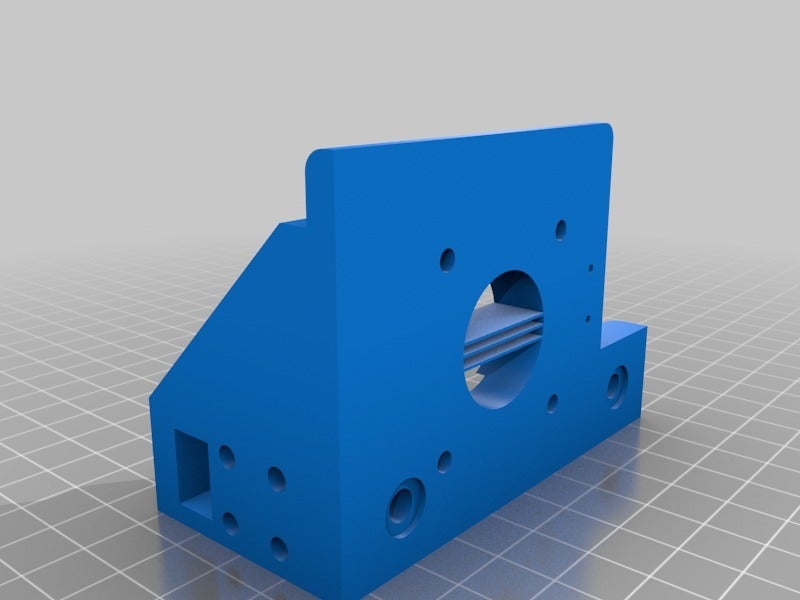

*Changed the spacing on the right hand idler bracket, it's now a 12mm 'gap' which allows for the 10mm wheel and two 1mm washers

*Changed all the 'mounting' nut holes for the 2020;s to M5 non self tapping. The stock M5x12's should now be fine

*Moved slightly the mounting holes to better spread the stress

*Tweaked the built in supports

V5 - YOU NEED TO PURCHASE AN M5x40 screw for the right hand idler bracket

ALL - You need 4 x M4 Bolts / Screws (per side) to fully use the tensioning function

- Altered Mounting screws for 20x20 on stepper bracket - now uses the factory bolts and T-Nuts

- Altered the geometry of the idler bracket to reduce the bolt length needed - it should now use a M5x40 bolt - which should be the stock one

- Altered the limit switch cutout depth a little

- Altered all the text 'depth' as 1mm was too much

- Removed the optional cutout for rails on the stepper bracket, it's always there now, now there's always a gap

- moved slightly the holes for mounting the stepper bracket to the 20x20

- Changed the built in supports slightly on the stepper bracket

V4 brackets measurements are slightly out, meaning that you have to use some new screws / t-nuts instead of the stock planned ones.

The brackets still work if you have new bits , but intention was to only use stock screws where possible - i'm re-designing a little

Of note so far - the bolts that hold into the 2020 extrusion T-nuts should be M5, i sized up M4

The idler holder bolt - should be M5x40, I've sized it M5x50

These brackets use all the stock screws / fixings

you only need 4x or 8x additional M4 screws if you want to use the belt tensioning function

EDIT - V4 Now good to go

Edited Supports in Stepper motor 'hole' - now very easy to remove

Edited Right hand side bracket to have a small 3mm hump - this means no additional parts needed, only 'stock' parts

/https://fbi.cults3d.com/uploaders/13783582/illustration-file/832d8d48-79cf-41ee-926a-4d474f314f7a/56757266_519703781893485_4620993594809909248_n.jpg)