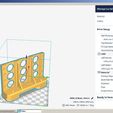

UPDATE 6/30/17- Made a few more minor adjustments, including altering the design slightly so that if you set your build plate size to 125x125 (the mini can handle it!) then you can plate both brackets and all the thumb screws in a single print. Added full plate STL.

UPDATE 6/29/17- made minor adjustments to the front and back bracket after yet another test fitting. We are getting close folks..

UPDATE: After printing out the brackets and messing around with them, I decided to make a couple of changes including... drum roll... thumb screws for the leveling screws so you can level it by hand with no allen wrench! This slightly changes the BOM, you no longer need the M3 Hex nuts, but will need 4 more square nuts and you will need to print four of the thumbscrew part.

WARNING: This thing has gone through multiple iterations and tests, but just as I was about to finish with what I am hoping is either the final version, or close to it, I have had a plethora of printer problems (all non-related to the project). This is essentially a beta-version that I am posting so that my comrades over at the MP Mini FB page (https://www.facebook.com/groups/1717306548519045) could have a whack at it while I am still working on it. If you make one, please let me know how it goes, I would love feedback and I am more than willing to make design changes (there will almost undoubtedly be design changes). I am also working on designing a partially printed bed extension carriage that uses some cheap aluminum L stock from home depot and I will link to that project once it is closer to ready. The links in the BOM are just for reference, but I would highly recommend https://www.trimcraftaviationrc.com, they are my go to for high quality and cheap hardware and they usually take only 1-2 business days for me to have my parts in hand. All told the parts can be obtained for around 15$ US.

BOM:

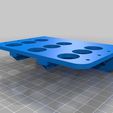

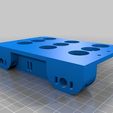

Front Bracket

Back Bracket

4x Thumbscrew part

2- 8mm x 300mm Linear Shafts (http://www.ebay.com/itm/8mm-x-300mm-Cylinder-Liner-Rail-Linear-Shaft-Optical-Axis-Good-Wear-Resistance-/172547455818?hash=item282ca13b4a:g:TyoAAOSw2gxYsAHA)

12- M3 square nuts (https://www.trimcraftaviationrc.com/index.php?route=product/product&path=77&product_id=549)

4- M3 hex nuts (https://www.trimcraftaviationrc.com/index.php?route=product/product&path=14_35&product_id=133)

8- M3x14mm Socket Head Cap Screw (https://www.trimcraftaviationrc.com/index.php?route=product/product&path=24_18_37&product_id=190)

4- M3x20mm Flat Socket Countersunk Screw (https://www.trimcraftaviationrc.com/index.php?route=product/product&path=24_3&product_id=350)

GT2 belt at least 350mm long (http://www.ebay.com/itm/3D-Printer-GT2-Timing-Belt-1M-Length-2mm-Pitch-6mm-Width-ABS-For-Reprap-Mendel-/292137200256?hash=item4404bbea80:g:gtcAAOSw~y9ZMGnI)

New Glass to cut longer bed (http://www.homedepot.com/p/8-in-x-10-in-x-125-in-Clear-Glass-90810/202091040)

To assemble begin by disconnecting your bed heater and thermistor wires from the mainboard. Next disconnect the belt by removing the tension spring and then carefully clipping one of the zipties holding the belt on. Pull off the carriage and bed by unscrewing them. Leave the 8mm rods in place, and using your new 300mm rods push the old ones out of the linear bearings so there is no gap and no chance that any of the ball bearings can fall out. Once the new rods are in put the two brackets on either end of the rods. The brackets are almost identical except for the placement of the belt attachment so make sure to keep track of which is the front and which is the back. Press the brackets onto the rods (it helps to dry fit all of this before installing it). Put a square nut into each of the square holes on the face of each bracket (there are 4 on each bracket) and then insert the m3x14mm socket cap screws into the holes on the sides and inside of the bracket faces to go into the square nuts and put tension on the rods. Don't tighten those screws until you get the printer bed and fit it to the bracket using the pre-existing springs and the m3X20mm flat socket countersunk screws. Put m3 hex nuts into the spots on the bracket you want to use and then install the bed onto the brackets. Once the bed is on and the screws through the springs look straight and everything looks nice and square, tighten the bolts on the sides of the linear rods to lock them into place. Install the new belt in the same way it was on the old carriage and use the spring tensioner (i like it on the back, but I could be wrong). Once the brackets are on, push the bed around to make sure the belt is on correctly and the bed can move easily. You are going to have to figure out a good way to hook up the bed heater, I am personally only going to use the bed extension to print PLA and material that doesn't need the heater so that there is less risk of wire fatigue and less of a chance of the printed bed carriage warping or failing. Once everything is on and moving freely, push the bed all the way to the back making sure it engages the y-limit switch. Mark the position of the nozzle and and then move the bed all the way forward (making sure its not hitting anything in the back) and then measure the distance between the two marks, and that's your new print bed size! I haven't figured out a good way to notch a glass bed, so right now I am using a 110mm x 200mm piece of glass that fits between the bed level screws.I recently improved the design to use thumbscrew for the bed level screws, so now you can put glass right over the top of the level screws and ratchet them from the bottom! whoot! You will need to put some super glue/thred locker/jb weld on the heads of the bed level screws to fix them inplace so the thumbscrews will work. So there you go. Please leave comments and feedback on ways this can be improved and if you have a mini check out the fb page above, I am pretty much constantly lurking there along with some pretty epic folks who are maxing their mini's like nobodies business!

/https://fbi.cults3d.com/uploaders/16626379/illustration-file/9872f056-c0e8-4731-8e65-0f00db18a025/brackets_installed.jpg)