Wall clock with manual mechanisms so that when opening the doors the bird comes out and when closing them it goes in. I have printed the model in 2 colors with an extruder, changing the color of the filament in Z: 150, except in parts 1,2 and 3 that have part of the roof and I have changed it in Z: 150.02. The dial I have changed the color of the numbers.

I bought the watch mechanism in Aliexpress, I leave the link in case you are interested: https://es.aliexpress.com/item/33030261667.html?spm=a2g0s.9042311.0.0.f03463c0B13I1M I bought the number 35.

I designed the hole for the mechanism with the following dimensions: 65x65mm without the upper curved part.

The maximum complete size of the watch is 376,669mm high x 366,239mm x 150mm deep.

The STLs I've left them ready to print in principle, but it will depend on the print size of each printer, etc.

Everything is printed without supports except the bird.

I set the quality to 0.2

I have printed the whole clock at 10% infill.

The flexi arms, the doors, the connecting sticks, the board at 25% infill.

the filling pattern I have set: octet

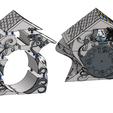

The assembly is easy in the pictures you can intuit a little bit:

THE STRUCTURE OF THE CLOCK is joined by sticks similar to those of the furniture, the sticks that are inserted vertically are 10mm ø, those that are inserted in the horizontal part are 6 and are 8mm ø. I recommend using a rubber hammer and carefully insert them until the end and the next piece fits well. The structure is from part 1 to 7. Part 5 gives an error in Ultimaker Cura, I haven't figured out why but it prints without problems.

The Sphere: it is divided into two parts, a ring with thread that is inserted into the structure and the sphere that is screwed into the ring. I recommend gluing the ring to the structure so that it does not move when screwed and gives more firmness to the structure. I recommend to apply some kind of lubricant to the thread so that it screws without clumsiness. I have designed in the sphere a support in the center that goes inside, it is easily removed with a suitable cutting pliers.

THE SLIDING TABLE the thinner part of the sliding table goes into the small window track. Pour lubricant on the rail to make it slide better.

THE HINGES are inserted into the holes in the window frame, the longer one at the bottom and the shorter one at the top. Maybe they need to be glued and in that case at the end of the whole assembly, I didn't need to glue them.

THE WINDOWS very important! on the RIGHT DOOR you have to check the option "print thin walls" for the correct printing of the grille. Insert the spouts into the hinges so that they rotate to open and close.

FLEXI ARMS you have to print 2, one for each window and you need 4 screws of metric 3. One end of the flexi arm is screwed to the inner hole of the window and the other end of the flexi arm is screwed to the board without being tight, so that they have movement. In the part of the door you have to screw it more but not completely, that will be well seen when everything is installed and the bird stuck on the board and as it is seen, screw the doors more or less until it opens smoothly.

THE BIRD is glued to the board in such a way that it doesn't clash when going in and out of the opening. I have done a post process of sanding to remove the support remains, also paint and epoxy resin to give it a shine.

HANGING HOLES: it is ready to hang it with spikes on the wall, in the back of the clock there are 3 holes in the form of square with a hole inside to enter the spikes without problem. The top hole is optional and the other two are more secure (I have used those) the distance from one spike to another is 150 mm.

I have also given epoxy resin to the drawings and the sphere, my advice is to let the resin rest for half an hour (depending on the type of resin more or less time) to prevent it from dripping, for the sphere do not let it thicken so much about 15 minutes.

If you have any doubt or problem, don't hesitate to ask, I'll try to solve it.

I hope you like it.

/https://fbi.cults3d.com/uploaders/15693871/illustration-file/a4bafbce-8831-4d30-b5d7-a91950f1b721/IMG_20210531_201603.jpg)

.png)

.png)

.png)

.png)