3D model description

See Video:

https://www.youtube.com/watch?v=ctuxhp6h6kc

The Slack Lack was greatly influenced by the Original Prusa Enclosure found here: https://www.thingiverse.com/thing:2864118

That being said, all of the design and CAD for this enclosure is my own. I wanted an enclosure for printing ABS but I also wanted to be able to leave the front open when printing PLA. I didn't want to have to leave the doors wide open as this sits in my living room, I knew I wanted pocket doors.

It is designed to be tall enough to hold an Ender 3 and a 30mm tall paving stone (helps in vibration reduction). The total usable height is 50cm. The doors hinge shut and latch via magnets. There are also support magnets in the hinge peices that prevent it from sliding while opening and closing the doors normally. The doors will slide back on tracks into the enclosure out the way. Finally, the doors can even be removed very easily by partially opening the door and sliding it off the magnets.

Purchase Parts Needed:

- Magnets 20x6x1.5mm Qty 12 (These were easier for me to find than the magnets sourced by the Prusa group)

- Screws 6x50mm Qty 8

- Screws 5x20mm Qty 14 (These were also easier to source, you'll need 2 more if you use my remote PSU bracket)

- Plexiglass 3x450x492mm Qty 3

- Plexiglass 3x214x492mm Qty 2

Printing:

- Expect to use nearly a full roll of filament!

- I printed everything in PETG, 20% infill, 3 walls

- I've made sure that all the parts were uploaded in their proper orientation for printing.

- SUPPORTS: Parts needing supports are Front_Spacer_TL.stl and Front_Spacer_TR.stl

- Print these parts 2x: Track.stl, TrackTop.stl, and Spacer_TB.stl

- Print Catch.stl 3x

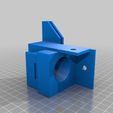

- IMPORTANT: The 4 pairs of hinge and barrel pieces that mate should have some friction and should not be loose. This friction is what keeps the hinge sections aligned when they are slid back in the enclosure.

Assembly:

- Assembly is straight forward, you can follow the same tutorial from the Prusa Enclosure.

- I used plain Elmer's style white glue to glue the upper and lower tracks to the plexiglass.

- Use super glue for the magnets.

- Use HoldFinder.stl to predrill your holes for the Catch's.

Additional Notes:

My Ender3 remote PSU mount is here (should work for original and Pro version, Pro version hasn't been verified): https://www.thingiverse.com/thing:3436078

LED strip mount that I used (2x per strip, 6 total): https://www.thingiverse.com/thing:2912036

If you have any questions feel free to ask.

UPDATE 16/3/2019

Added step files for the parts with magnets so you can easily adjust the size of the holes for magnets that you can find locally. When sizing your magnets try to keep around a 1kg pull strength.

UPDATE 22/3/2019

Added an exploded view per request as a picture and a higher res picture in a zip.

UPDATE 23/3/2019

If you need different holes for your magnets, see user kenrobertson's remix. I would advise to try to keep the pull strength around 1kg.

UPDATE 23/6/2019

The number one request has been for access to different sizes for the Plexiglas. I'm not going to make different versions for all the requests, but I've went ahead and uploaded step files for all the parts in a single zip "EnclosureAllPartsExport". Anyone should be able to use these so they can modify the parts to fit their specific needs.

/https://fbi.cults3d.com/uploaders/15575507/illustration-file/0189d2e4-d628-4d3c-8f49-58819a2110f6/IMG_20190311_220936.jpg)