3D model description

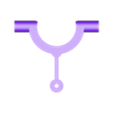

This type of Stirling engine, known as the beta configuration, features just one cylinder with a hot end and a cool end. The working gas is transferred from one end of the cylinder to the other by a device called a displacer (here the marbles do the job of displacer). The marbles have a smaller diameter than the cylinder, thus their motion does not change the volume of gas in the cylinder they justtransfer the gas from the hot end to the cold end. Motion of the marbles is obtained with an appropriate inclination of the cylinder. When the gas expends, it pushes the syringe piston which turns the wheel and reaches a heigher position, the marbles will roll towards the hot end... The gas beeing pushed toward the cold end, it retracts and pulls the piston which returns to its bottom position. Then the marbles are rolling toward the cold end driving the gas toward the hot end, and the cycle goes on ...

Well, it's easier to see it running here ;-)

Please, don't forget to turn the sound ON as the engine generates a nice mesmerizing (and annoying !) music ...

http://youtu.be/i0iqq27CjOs

3D printing settings

Everything is printed in PLA using 0.5mm hot end and 0.2mm layers.

BOM :

- a 2ml glass syringe (eg: http://www.ebay.fr/itm/151541134290?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649 )

- one 18mm outer diameter borosilicate test tube (14.5 cm length)

- 4, 2mm O rings 2x fitting the external diameter of the test tube and 2x the syringe

- some PTFE plumber tape

- a piece of 3mm carbon rod

- one 3mm nail (used as axis of the wheel)

- 2x 2mm nails (used as axis for the tube)

- one little screw

- 3 glass marbles running freely inside the tube

Be sure the syringe has absolutely no friction. If it is not the case, run in it using some copper cleaning paste and water.

Insert the marbles inside the tube

roll some PTFE tape aroung the syringe and insert an O ring on top of this

put the second O ring at the other end of the syringe (used to center it)

push the syringe inside the tube. It must be air tight. If not add some PTFE under the O ring.

Cut a piece a 3mm rod (2.5 cm or so) and insert it inside the holes of the two supports. Roll the big O rings on the test tube and press fit the support. That's enought to support the tube. Use the 2 nails to make some nice axis.

The tube shall be balanced to keep some weight at the level the piston head whatever the marbles position.

The screw allows to trim the rest position (see the pictures)

Note that the wheel shall run freely on its axis... There are a nut and a screw but they are not used here .

All the rest is very simple, just watch the movie !

WARNING: as the engine operates with an alcohol burner, there is a flame and the hot end reaches a very hot temperature and remains hot a long time after the flame has been turned off. In other words, this is not a toy for young kids... Always operate safely under an adult supervision!

/https://fbi.cults3d.com/uploaders/21802002/illustration-file/a1196655-002f-4687-b445-d2068c80fa07/marble_stirling.gif)