UPDATE 13-May-2020:

1. Thank you to pboucher14 for noticing that I had incorrect hole spacing on the 21_cup_underlay_lack part. Those holes now line up with the rest of the parts.

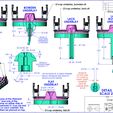

2. Added view to 2D drawing to define dimensions of the M10 coupling boss. Mainly so that I can refer to it later when designing other things with M10 pass-through couplers.

UPDATE 28-Jan-2019: As discovered by benwa1869, I somehow failed to upload the STL for the Lack Bowden underlay. Sorry about that!! Added to files now.

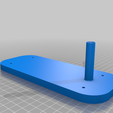

UPDATE 16-Oct-2018: For my desktop porinter at work, I modified the "21cup_base" part to remove the feed cone and screws, and to shrink the footprint from 200mm to 150mm. This part is called "tabeletop_base".

I often print PETG and sometimes Nylon, and I wanted to have relatively airtight containers that I can print from within. I have a shelf above my printer where I like to place my filament.

I mentioned to my buddy Jason Foss (https://www.thingiverse.com/captfoss/about) that I had been looking for an airtight cereal container that didn't have the inset notches on the sides that interfered with a spool. He told me about the Rubbermaid 21 cup container and it was perfect. I searched Thingiverse and found several things using this container. I tried out a few of them and none of them fit my needs exactly, so I decided to design my own. There are the things that inspired my design:

Filament Spool SyStem (https://www.thingiverse.com/thing:2769588) by Jimbo70 (this was my main inspiration and is fantastic)

Custimizable TUSH bracket (sized for Rubbermaid 21 cup filament storage) (https://www.thingiverse.com/thing:2781034) by x0pherl

TUSH2 - Sliding Positions (https://www.thingiverse.com/thing:2853619) by spongybob1958

The main way my design differs from Jimbo70's is that I wanted to make the the filament path more guided and easier to thread. I also wanted the whole assembly to be easier to assemble and also easier to adjust the spool width.

I adopted the TUSH design on sliding rails from spongybob1958, which are fantastic. I incorporated the rails directly into my base part and I modified the TUSH parts slightly to add relief at the inside corner of the rail channel. I also added an edge chamfer in the same location. These two changes eliminated the need to fine tune the first layer height to eliminate elephants foot, so now the parts are easy to print an work without any post-processing with a razor.

I posted the work in progress to our FB group and one of the requests was to make a longer underlay (the lower printed part that has the tube that passes through the shelf) that had a tube long enough to pass through the near-50mm thick top surface of a Lack enclosure.Done.

I was also asked to add a version that had a bowden connector to keep the system airtight. At first I was reluctant because I was worried about the filament jamming up inside the tube while trying to feed it through. You'd be pushing the filament from several tens of mm back from the tip, and with the natural curve to any filament coming off a spool, it is very easy to snag even a tiny lip and jam up. But, mainly due to peer pressure from my buddy Olof Ogland (https://www.thingiverse.com/Olorf/designs), I gave it try anyway. Well, it wasn't quite as impossible as I had assumed, and I was able to find diameters that would allow for no internal lips in the filament path. You do need to trim the inlet end of your PTFE tube with a conical shape having a input diameter of greater than 2.2mm. Done!

OK, so the assy process (for each Silo) is as follows:

1. Print the following:

one "21-cup base.STL"

two "TUSH2-Outside_tweaked.STL"

two "TUSH2-Inside_tweaked.STL"

one of the underlay parts of your choice:

"21cup underlay_std.STL"

"21cup underlay_bowden.STL"

"21cup underlay_flat.STL"

"21cup underlay_lack.STL"

"21cup underlay_lack_bowden.STL"

2. Hold the "base" to the lid of the Rubbermaid container. The lid should face upwards on the shelf so, so the "base" goes on the inside surface of the lid. The "base" will self align to the lid.

3. Turn the lid over, and using the "base" as a guide, mark the 5 locations where you will need to make holes in the lid for the 4 screws and the filament.

4. Drill the 5 holes in the Lid. The holes can also be made with an xacto blade. they do not need to look pretty, as they will be hidden. the size of the hole is unimportant, as long as the are larger than the screws and filament. The "base" self-aligns to the lid, so good hole to screw tolerance is not needed for alignment.

5. Drill a hole in your shelf or Lack table for the exit tube of the chosen "underlay"to pass through. See attached dimension drawing for external diameters of the various underlay versions.

6. If you are using one of the Bowden versions of the underlay, trim the input end of your PTFE tube as shown in the attached dimension drawing. Screw the Bowden coupler onto the Underlay tube. The diameter of the tube is such that the coupling can form its own threads without cracking the tube. feed the PTFE tube through the coupling, ensuring that it goes several mm past the coupling until it seats into position, as shown in the dimension drawing. Alternately, you can feed the PTFE through the coupler before screwing the coupler into the underlay. Then insert and seat the PTFE tube first, and then screw in the coupling.

6. Place the "underlay" on the bottom side of the Lid and place on the shelf or Lack table with the exit tube of the underlay passing through the drilled hole.

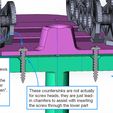

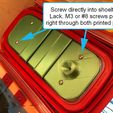

7. Attach the whole assembly to the shelf or Lack table using 4 screws (#8 or M3). The "base" self-aligns to the Lid and the screws will align the "underlay" to the "base".

8. Assemble the TUSH parts and slide them onto the rails of the "base".

9. Adjust the width of the TUSH rollers and place your spool of filament on the assembly, with the filament exiting the spool over the top, so it can feed relatively straight down through the input side of the "base".

10. Feed your filament though into the input cone and it it should feed freely out through the exit orifice, whether than be the printed underlay tube or the PTFE tube in the bowden versions.

As always, STEP and native Solidworks CAD assemblies are attached as well as the STLs.

Thanks!

/https://fbi.cults3d.com/uploaders/14115355/illustration-file/b9d9e8a6-971e-43bf-b169-e9ee2e8e4605/Ocies_Filament_Silo_Assy_Rev02.jpg)