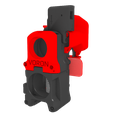

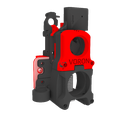

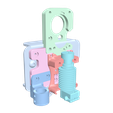

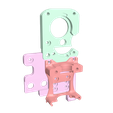

Trying to mount the VORON Afterburner direct drive print-head to CR10S-Pro with stock gantry plate.

Based on VORON 2.4 Afterburner tool-head.

http://vorondesign.com/ for more info and original STLs

You need almost everything that requires to build a standalone Afterburner print-head. You can also get some more details at the Afterburner beta page:

http://vorondesign.com/voron_afterburner

E3D V6 hotend is required.

NEMA17 42x20mm short stepper motor is required.

Credits

* VORON Design team for their wonderful VORON and Afterburner direct drive design (www.vorondesign.com)

* k1nb0te for CR10s Pro / Max cable chain (https://www.thingiverse.com/thing:3735352)

* iogosantos88 for Drag Chain - Cable Chain - Ender 3 (https://www.thingiverse.com/thing:3715002)

* 3DBG for the 4020 hotend fan mount

* mediaman for his famous Hero Me for CR10S Pro, I borrowed his ABL mount design.

(https://www.thingiverse.com/thing:3433619)

Guide

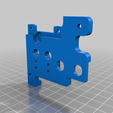

1. First of all, you need to know the basic of VORON Afterburner. You need to download VORON 2.4+ STLs, and find X carriage parts, where original VORON Afterburner parts located.

2. You need M3 screws in different length, from 40mm to 6mm; at the same time, some M3 threads and M3 nuts. You may reference Afterburner beta installation manual or VORON 2.4 installation manual. There are some small changes about screw usage, but very minimum.

3. E3D V6 hotend + BMG direct drive exdruder kit set is mandatory

4. 42cm stepper motor in max. 23mm depth. I am using 23mm stepper. Thicker motor will have clearance issue. DO ADJUST E1 VRef on the mainboard to have the proper current for the new extruder stepper. The stock Creality stepper was 1.5A, for instance, my 23mm stepper is 1A, I tuned the VRef E1 voltage down to 0.8V. (how-to reference: https://support.bondtech.se/Guide/22.+Creality+3D+CR-10S+Pro+-+Stepper+Current+Adjustment/47?lang=en)

5. After the hardware installation and modification, don't for get to re-calibrate E-step for the new extruder and the PID for the new E3D V6 hot-end.

6. ABL offset: X-45 Y0 Z0 working flowlessly

PRINT

* ABS and ABS+ is originally recommended by VORON team; PETG should work fine on CR10S Pro without an enclosure.

* Please rotate the part to build plate by yourself

* most parts don't require support to print; some might need support, but try to avoid supports in the inner structure, especially filament channel and screw holes.

* 4+ walls, 5+ buttom&top layers, 40+% infill is recommended by VORON team. If you want to save some weight, try different parameters in non-structural parts with your own experience.

MODULES

* Afterburner (base)

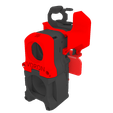

* Drag chain link cable management module

* Filament sensor module

Change Log

2020.06.11: Filament run-out sensor tested and fixes done

* Yeah, the filament run-out sensor works like a charm, now only 10mm filament will be wasted if it runs out. There might be occasional glitches when the filament backs out, like it gets out from the back (doesn't affect much), or it won't get out ( easy fix, since AB has a hot-end quick release design, and it's very easy to clear out the left filament).

* The tolerance issues that mentioned on the last update are all fixed. I didn't tested to print them yet, because it were tiny issues, I did fixed them on my initial print easily by filing and drilling a little bit. The fixes are just for perfection.

* TPU, PETG, PLA are all tested. TPU had some extrusion failures occurred, so you still need to handle it with care, direct drive won't 100% make it easy to print.

2020.06.10: Initial testing

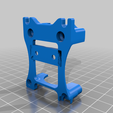

The module assembly was perfect. Then I did finally mount the AB tool head to my CR10s Pro, to replace the stock hotend + Hero Me gen4 combination.

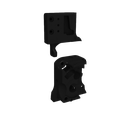

The mounting proccess was mostly successful and smoothly. The only issue was some tiny misfits on the X carriage frame, the tolerance for all screw holes are just fine, the issue was only the two big holes for the stock hotend mounting bulges, I drilled them a little bit to make them fit. Anyway I will fix the issue next time with the part.

There also a tiny misfit with the filament sensor box back piece (you don't actually need it tho, it's just for appearance integrity. If you don't install it, it's a 3g weight saving), will fix it later. Duo to lacking of extension cable for the filament sensor, I haven't install the module and didn't test it yet. The assembly was perfect tho, I'm sure it will work fine.

The tool head fits pretty well, and well-balanced on the gantry IMO. In my case, there is an overheat issue with the extrusion stepper (it's hotter than other stock steppers), I think the new stepper has lower voltage than the stock one, I will add a buck converter to fix that. But it's not a design issue anyways. Overall, I'm pretty please with the first test.

Last but not least, I will mention the biggest concern during my installation and testing. It was the bed height. The hotend tip on the AB toolhead is much higher than the stock hotend, which makes the X carriage having to be much lower than before. It almost hit the bottom limit - actually the X carriage end hit the Z stepper mount bar many times during the test, because the hotend is not lower enough to the hotbed. I raised the hotbed almost to the highest, and thanks god, it works just fine, although it's a close fit. I'm using a aftermarket magnetic flex steel surface (with PEI), it's much thinner than the stock removable aluminium plate or glass plate. So if you are using the stock print surface or glass plate with enough thickness, this concern will be minor.

And here are the following works to do on the project:

* Fix all part misfits that mentioned, add more tolerance

* Design a new drag chain mounting part on the PCB side

* Testing the filament sensor module

2020.06.01: filament sensor module

* filament_sensor_front - filament sensor module for original CR10S Pro sensor switch/chip set.

* filament_sensor_back - back piece of the filament sensor module, not mandatory

* extruder_body_fila_sen - extruder body part that used to mount filament sensor module with 2 M3 screws.

* 5x1mm_washer - you might need this for the extruder gear axle, please use in need

2020.05.27

* motor_rack - initial version of a clean motor rack; use with extruder_motor_plate (normal thickness)

* motor_rack_V3 - full function motor rack with cable chain link end; use with extruder_motor_plate (normal thickness)

* [a]_connector_cover - to hide cables and connectors; use with full functional motor_rack_V3

* chain-link_extruder_side - the first link to connect the chain end on the motor_rack_V3. Get other links here: https://www.thingiverse.com/thing:3715002

* hotend-4020-fan-mount - the hotend fan mount for 4020 (Noctua) fan, modified by 3DBG. If you use 4010 fan, just use the original by VORON.

* Cable chain mount on the other end is still WIP

* Filament sensor solution is still WIP

* Everything is still in the testing phase of part assembly

2020.05.22

* extruder_body - remodeled from the latest VORON update

* extruder_motor_plate - remodeled from the latest VORON update

* extruder_motor_plate_thick - an alternative 'thick' version for motor with longer axle.

* printhead_rear_e3dv6 - enhanced the M3 thread mounting leg; removed the central screw mounting bar from the initial version for the original quick release function (VORON original design)

* printhead_rear_e3dv6_B - with extra screw mounting bar to mount the part to the carriage plate to ensure a better stability. It is actually not necessary, and it defeats the pint-head quick-release from the original design. But if better stability is your thing, this alternative is what you want

* From this point, I think the whole thing should be functional. I am still working on cable management and filament sensor mount solutions.

2020.05.15

Initial upload

/https://fbi.cults3d.com/uploaders/21432215/illustration-file/7289a422-6fcb-4fc7-83b1-67fa654837c7/_20200612011816.jpg)