Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

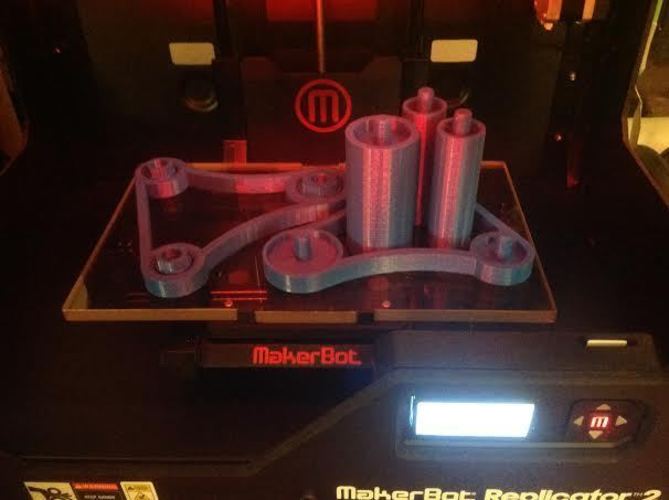

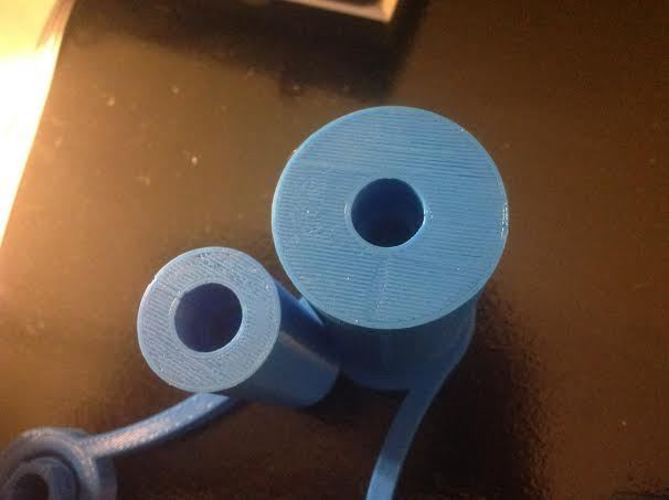

THIS IS AN OBSOLETE VERSION OF THIS SPOOL HOLDER Here is a completely redesigned version of this spool holder that is 100x better in nearly every way... http://www.thingiverse.com/thing:943563/#instructions THIS IS AN OBSOLETE VERSION OF THIS SPOOL HOLDER Here's a video explaining how this spool holder works... https://www.youtube.com/watch?v=CmDmW-NRSjM&feature=youtu.be Here's a similar spool holder I made for Taulman brand filaments... http://www.thingiverse.com/thing:938437 Prints entirely in one print, if you want Extremely Stable with perfect dimensions Connects and assembles brilliantly Rigorously designed to be as durable as possible Engineered with the utmost mathematical rigor Completely portable - works and supports wonderfully, without any issue, while PLA is printing from the spool... Easiest PLA color swaps to the extruder imaginable. *With various sized rods in the thing files, you can make this fit almost any spool... I've gotten it to fit on over 7 brands including Makerbot, Hatchbox, Gizmodorks, Ninjaflex, 3dxtech, prototype supply, etc... Pretty much every one... This was my first big project after purchasing my replicator... I spent a lot of time making this, and I'm very proud of the finished product... After unboxing my Makerbot and printing all the stock prints that came on the SD card, I was wondering what should be my first "thing"... Since I had about 3 spools that I purchased with my bot just laying around - sad, lonely and with no place to call home, I decided I should make them all a little cradle to rest in happily ever after, because - afterall - I LOVE to keep my amazing little robot happy, therefore, I make damn sure to take diligent care of my Makerbot's food... So far our relationship has been fantastic - Makerbot and I - however the first real dislike I had with my Makerbot was the stubbornly perplexing spool holder thing that came with the machine. A spool holder that grudgingly attaches to the back of the machine - only to refuse to want to come back off to change spools, at least not without first waging all out war on my increasingly fragile emotions. Basically, I found it difficult to change spools quickly, effectively and without issue using that damn thing. So I decided my spool holder should be designed so that it could simply be placed in the back of the printer, without any adjustments, and feed straight into the extruder while cozily chilling in its sweet little cradle. Overall, I wanted to make it elegant yet practical, while using the simplest and most discrete design possible. I went through a lot of ideas - my original designs look absolutely nothing like this one - but through extensive prototyping, I arrived at a design and final product I'm satisfied with. The coolest feature, I think, is the spinning nuts located in the connector arm... (Which I have as its own thing for use in any prototype you want on my page - see - "NeverLost Nut & Bolt Spinny Thing")... The part is cool in that the nut is permanently confined within any "thing" you add it to - it will never fall out - yet still prints as one piece without ever fusing to the shell surrounding it... It is designed in a way that allows it to spin freely while never separating from the shell or bigger part that encompesses it. The complementary hollowed out base containing a perfectly sized and scaled screw that is located in the geometrical center of the base, slips flawlessly into the nut with little to no need for alignment or effort - all while still maintaining a very tight grip... Another awesome design feature of the "thing" is - due to the nut's free range of motion and the hollowed base the screw rests in, creates a - never fail - super tight grip between the two pieces, thus optimizing the connection... While the nut tightens, it sinks into its shell, this applies a strong force against the shell and thus the entire part - more importantly though - due to this sinking - while it tightens it concurrently extrudes through the bottom and snugly enters the hollow base surrounding the screw, further tightening the grip and adding a much needed level of support to the fragile plastic screw. These mechanics are much more durable and effective when compared to simply screwing two pieces together along flush surfaces with no snatch or support to defend against unwanted torque. The one inherent flaw of building with plastic material is that it has a very high risk of breaking or snapping when small support pieces are over torqued. This unavoidable weakness is a contingency that I make sure to address while engineering everything I design in an effort to maximize the durability of everything I build... It's kind of hard to explain this feature without visual aid, but if you print this thing and try it out - you'll see exactly what I'm saying. All in all, it provides a lot of longevity and durability to the apparatus entirely. This was a very tedious little part that I became very obsessive with designing. It took me an entire weekend, about 50 prototypes and nearly an entire spool of PLA to perfect - however - I managed to get the dimensions synced perfectly down to < 0.1mm... So, unlike OJ's bloody glove, this thing will slide on effortlessly, and without acquittal. Although this piece (my "nut and bolt" thing, not this spool thing) takes less than about half an hour to print in standard quality, I've successfully printed it in every level of quality makerbot offers and it work

Comments