Important Update:

SWITCHED TO NEW SETUP (Remix)

=> see https://www.thingiverse.com/thing:4263807

This solution is far more easy to assemble and needs less parts. And the filament is much easier to change. BUT, this version here is a little bit more robust.

See the thing also for using silica gel!

Version 1.1.(Text only update)

Version 1.0 (complete)

Version 1.1 (with end cover on tube)

Update 2019/01: Parts: Hint how to search for drybox feeders on thingiverse. Tip to use teflon tube inside the housing (& photo)

Intro

[V REMIX] -> it was not easy enough to change filament. So I switched to the solution of https://www.thingiverse.com/thing:859426 from https://www.thingiverse.com/ant0ni0 which was way more easy to handle.

[V1.1] After fiddling around getting the filament into the feeders between spool and frontplate, I urge everyone to PLACE THE FEEDERS AT THE TOP of the front of the box, not as shown at the buttom! Makes life and handling much easier.

One of the many solutions to make a dry box with IKEA SAMLA. I looked for an easy and complete "solution system" ;-)

Inspired by: https://www.thingiverse.com/thing:743280

The parts are so constructed, so that the base is 5 degrees tilted like the SAMLA side panels are.

Parts

- I am using a SAMLA type of 40cm long, 28cm width, 28 cm height which are 22 liters.

- My aluminium tube is 30cm long which gives it a tough fit.

- I am using standard 16mmx3mm SPAX screws for the side panel base.

- For the feeders I am using M5 screws, nuts and some small M5 washers.

(Mostly) optional parts

You definitely want some of these ;-)

- Spacer: https://www.thingiverse.com/thing:728531

You optionally might also wish but don't have to print one of these ;-):

- Spool adapter: https://www.thingiverse.com/thing:735213

- SAMLA Clips: https://www.thingiverse.com/thing:2110134 (use the one for 22 liter, if you are using a SAMLA case like mine)

- other forms of drybox feeders: search at thingiverse for the words "drybox feeder" or "angled drybox feeder" and you will find a lot of parts, if you do not like mine.

- I also use short teflon tubes on the inside of the housing. This hinders the roles from spinning too far, so the filament clutters (see photo).

STL

The STL set comes with 3 main parts:

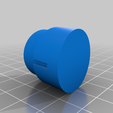

- The fittings for the aluminium tube. It is a standard 25mm (outer diameter) / 22mm (inner diameter) aluminium tube.

IMPORTANT: The fitting has a marking, that should point upwards when mounting the parts and also later setting the tube into the base.

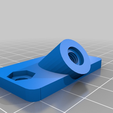

The side panel holder to screw on the wall.The opening shows upwards - should be clear ;-)

A cover for the panel holder so spacers would not interfere. Fits onto the 25mm tube and stays there.

Probably you won't need this if your spacers are big enough and stay tight to the tube. But I use small spacers with a diameter of 25.5 mm and only 5mm thick - a little bit more than the tube. These can make problems together with the spool adapters at the end of the tube. Test for yourself or in case: use bigger spacers!

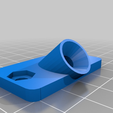

- Angled dry box feeder in a few variations: (I don't remember, where I got those).

I added an outside feeder that takes a standard M6 adapter for Teflon tube (which are more common then the bigger ones). You can use the one with or without an hexnut hole. One for the bigger teflon tube holders is attached as well.

I also added a version with a hole offset for mounting on the side of the SAMLA where a gap exists - so the two parts of the feeders won't fit together any more. The filament will not go through straight. You have to mount the feeders with a little offset.

Mounting

Part [1]: Before put into the aluminium tube, make sure both parts are aligned the same way. Put a marking on both sides of the tube. Use a hammer to insert (plastic hammer).

Part [2]: Align properly, so the filament roles leave space at the ground for silica gel. Also put the element a little bis of axis, so there is more air for the filament / feeder.

Part [3]: Mount onto the tube. Should slide in without problems.

Part [4]:

Burns down to:

A. Two feeders in the middle of the side panel. Place them at the top of the box(see Update version 1.1). Just print two of inner and outer feeders (with or without hexnut). But don NOT use the one with the offset holes.

B. Two feeders at the outside of the side panel. Place them at the top of the box(see Update version 1.1). Print two inner feeders and two outer feeders. For the outer you need to consider the at the SAMLA side panels. Therefore print two of the outer feeders with offset holes or drill down the wholes and use washers (like me) to get the same effect.

Detailed explanation for the feeders

You might need to use some washers for the outer feeders because of the edge in the SAMLA housing (See picture).

For the outer ones you also need to use the outer feeder parts with a little offset because of the gap. Therefore drill the whole downwards (see picture) or use the special one with the offset holes.

Also don't forget to drill a whole between the two parts into the SAMLA housing to get filament through ;-)

/https://fbi.cults3d.com/uploaders/29318706/illustration-file/e25c5e45-55a4-4d86-9d49-b107bb40d44d/20180808_161412.geaendert.jpg)