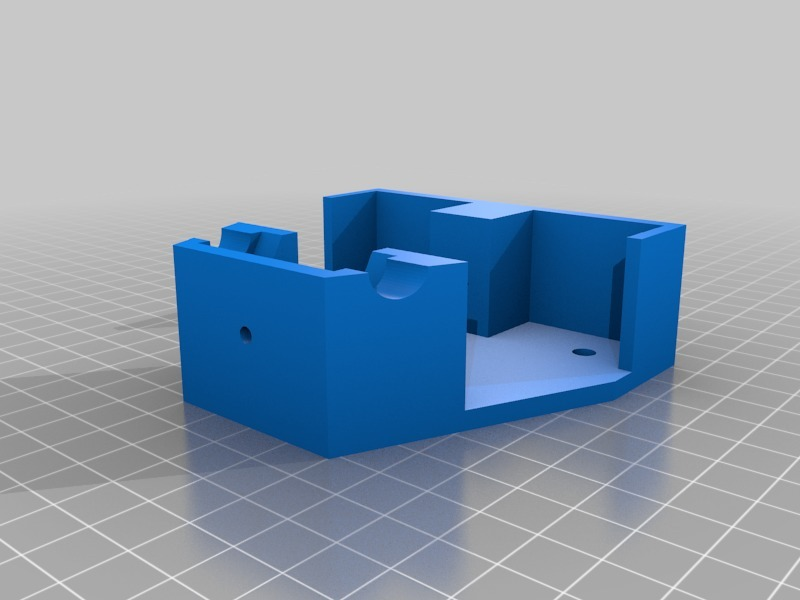

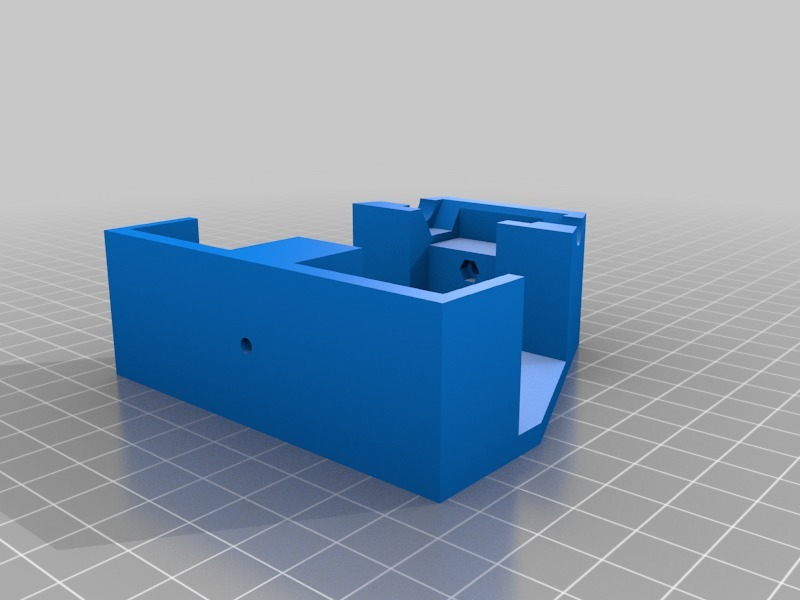

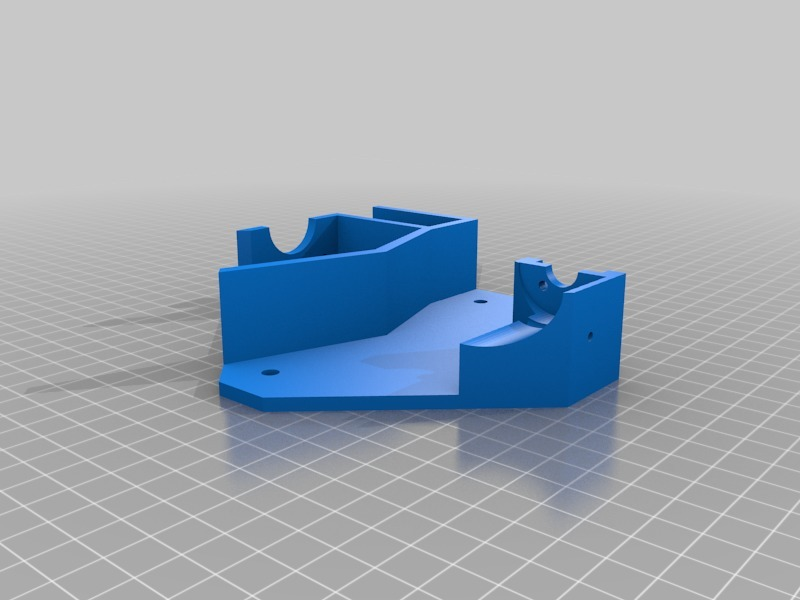

Most Printed Parts Computerized Numerical Controled Foam Cutter short: >MPP CNC FC<

Materials:

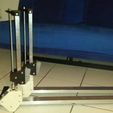

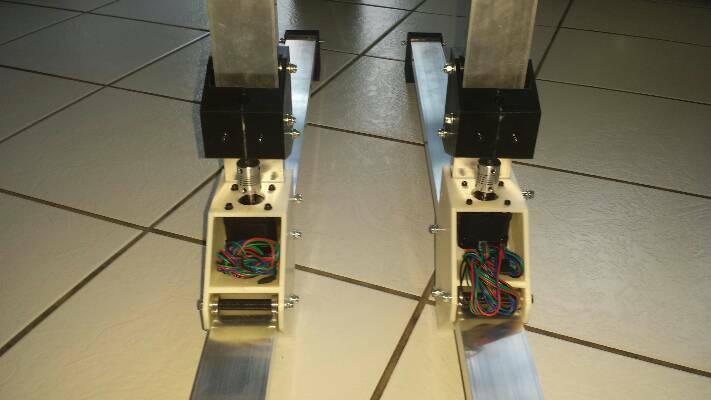

20x50x2 mm aluminiumtube . I use 1000 mm for x-axis and 500 mm for y-axis on both sides

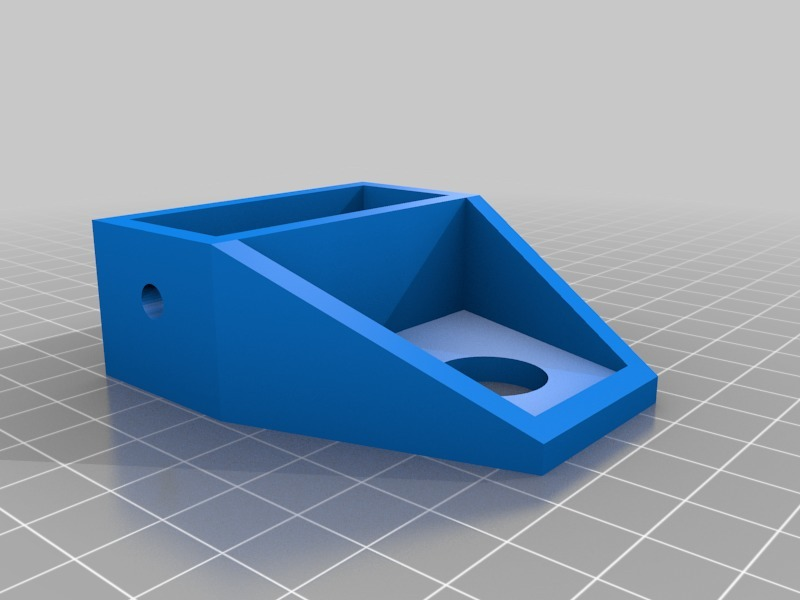

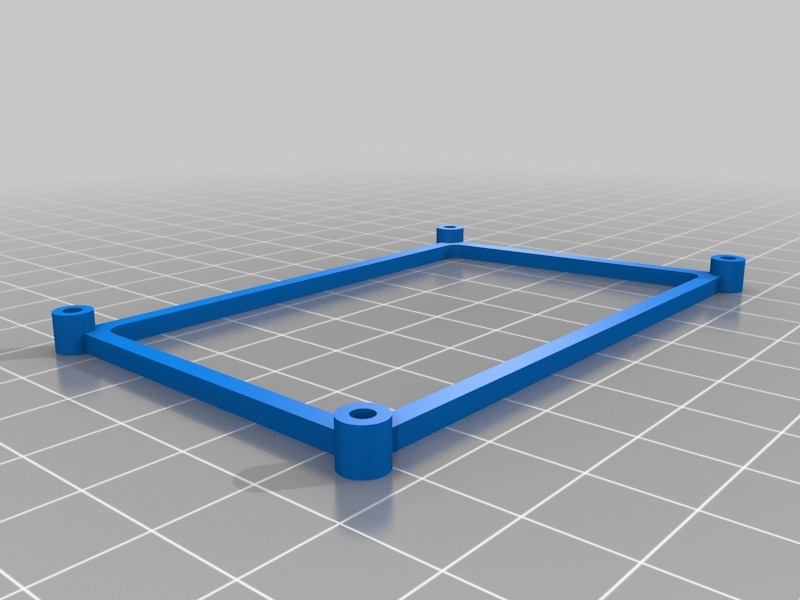

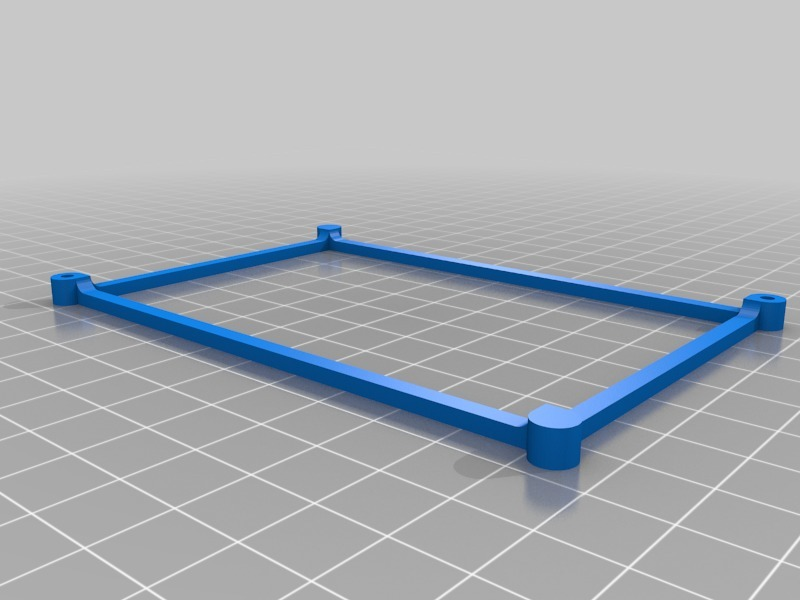

Print all things in PLA, ABS or PETG two times and glue together the x and y wagon parts with CA-glue

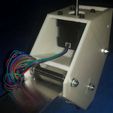

Control board will be a Arduino Mega + ramps 1.4

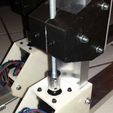

4xNema 17 stepper

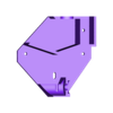

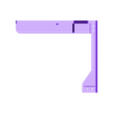

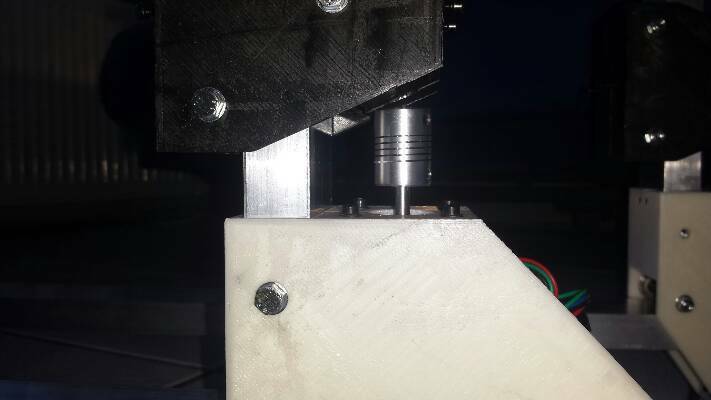

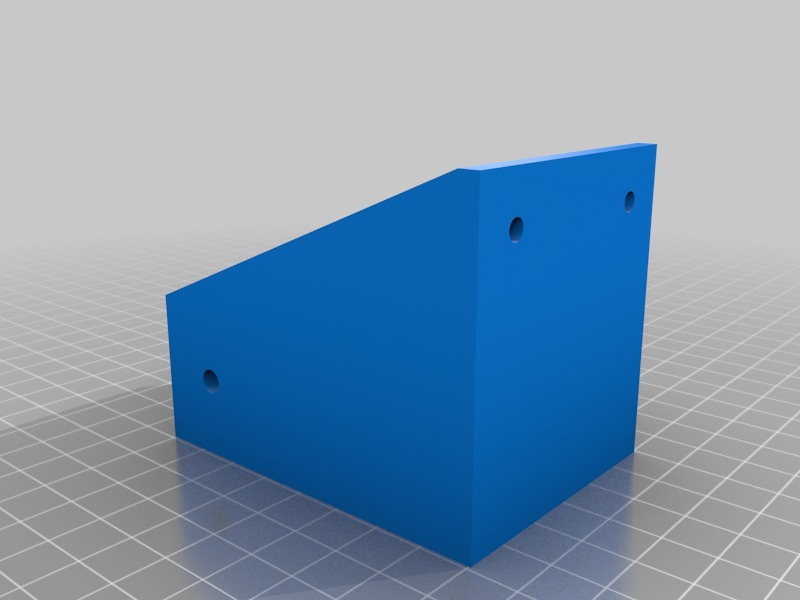

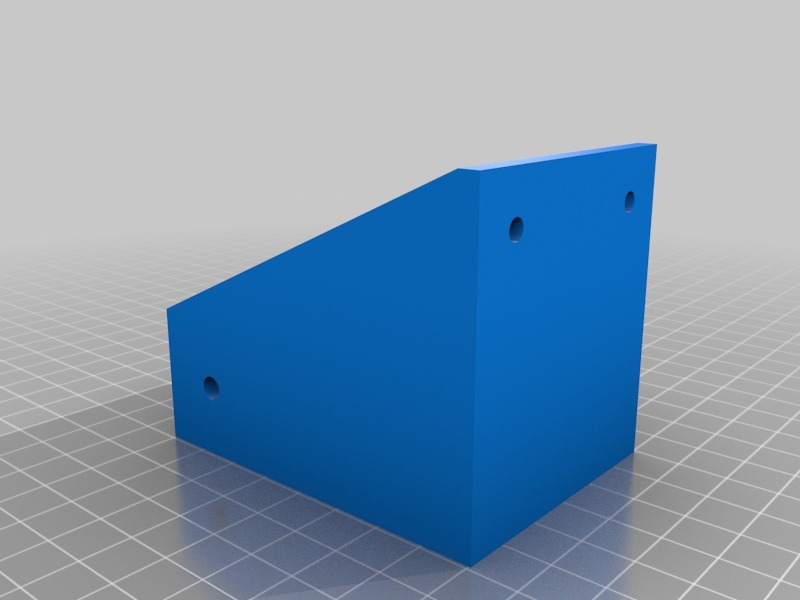

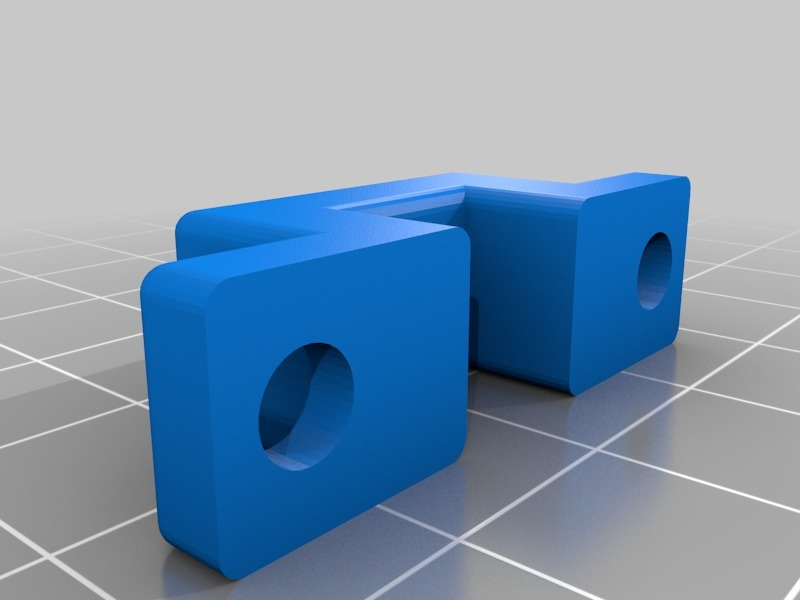

8 mm threaded rods (both ends of the rods must be finished to 5 mm diameter with lathe and one side in adition a 5 mm thread to build a fixed bearing with the parts: Halter_y and Kappe_z) other sides are flexible couplings to the Nema steppers.

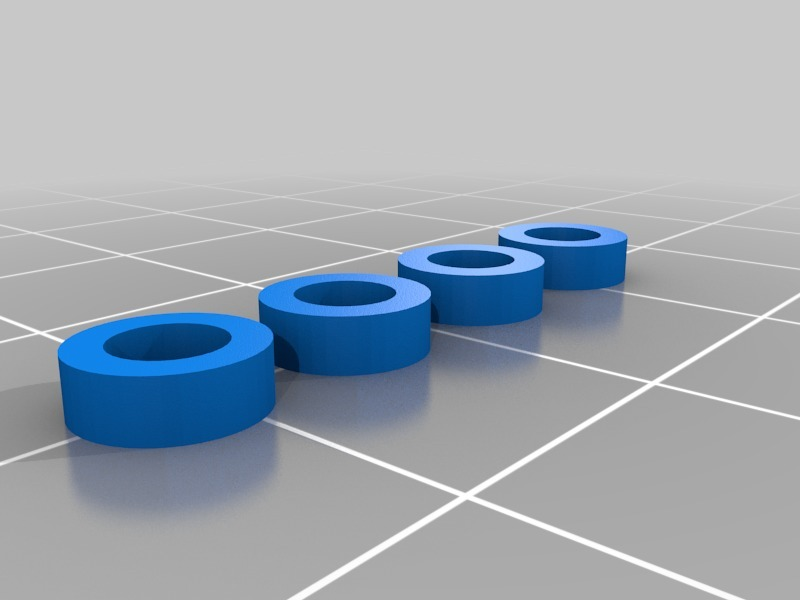

30 pc. ballbearings f625zz are neaded

20 pc. 75mm M5 bolts, nuts and many washers. Use washers ever between screws, bearings and plastic!

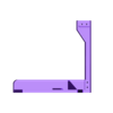

Be careful while mounting the bearings! The spacer <Abstandshalter422< must be 42.2 mm after softly tighten the bolts and nuts! The bearings must be mounted in rectangel to the aluminiumrails. Otherwise the rails will be damaged after short time of use.

The dimension of your machine may be different to mine so you have to customize the length of the threaded rods.

The hotwire got a bow. I use aluminiumtube and 8 mm glasfiber rods (old things from a tent) as arms to tighten the wire on both sides.

Later I'll post a picture of this part. It's under construction.

Software will be: DevCNC.foam and DevCNC.wing for cutting wingprojects in RC modelling.

http://www.devcad.com/eng/devcncfoam.asp

(Any other Software which controls 4 axis cnc machines is possible. For example Mach3 or Linuxcnc together with Profili Pro wich is able to save 4-axis-gcode)

Updates:

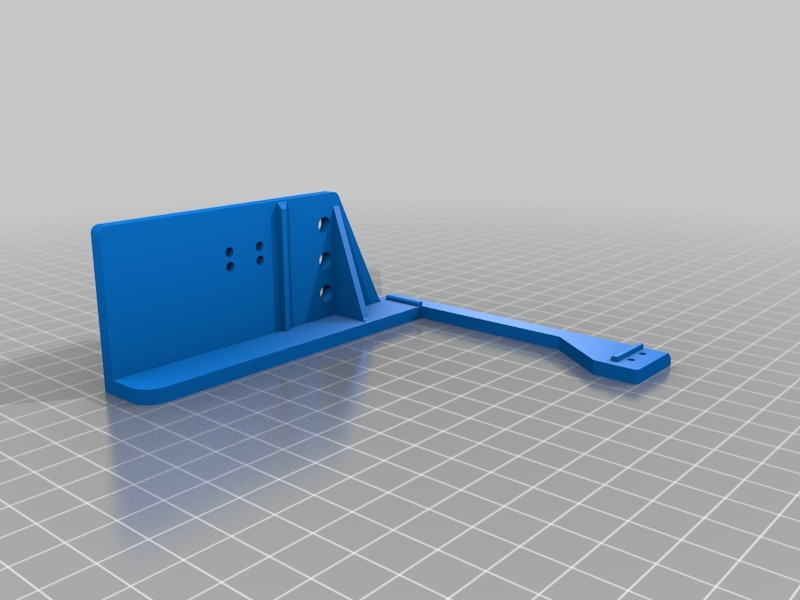

03-28-2017 Add the file >Sockel< it is the baseplate for a sheet of aluminium which hold the hotwire and will be mounted at frontside of >wagen_z<. On top you find a 8 mm hole. Insert a stick there long enaugh for holding the hotwirebow at the upper end.

03-30-2017 Added pictures with threaded rods after assembling

04-02-2017 Added pictures showing Hotwire holders and bow holders made from aluminium and old black gfk tent rods...

publishing new files for wagen_y and wagen_y_2 and a leadscrewbase. So you are able to use a simple M8 nut as a leadscrew in y, too. Put the nut in and fasten it with two M3x16 screws. (Cutting a thread before is not necessary).

If my endswiches are shipped (from china) I will draw some holders for this switches. Solong stay tuned...

I think this thing is 99% ready now. Please mount it on one, or better two small wooden baseplates so you are able to adjust the space between the towers. While fixing it with clamps on a table. And maybe you spent some energy chains to manage the cables....

04-21-2017 ...still waiting for the arduino mega and ramps unit... Sorry but that is a chinese shipping problem...

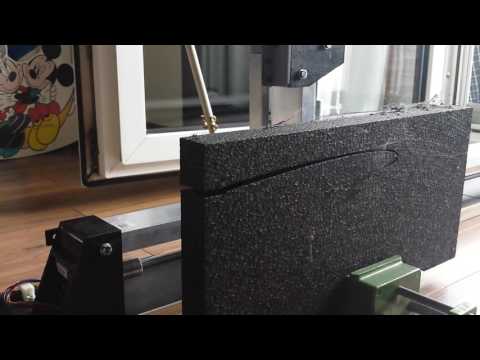

04-26-2017 First run video - with arduino mega and ramps 1.4 and DevCnc foam (unregistered) as software: https://www.youtube.com/watch?v=lNyuF1vNXZ4

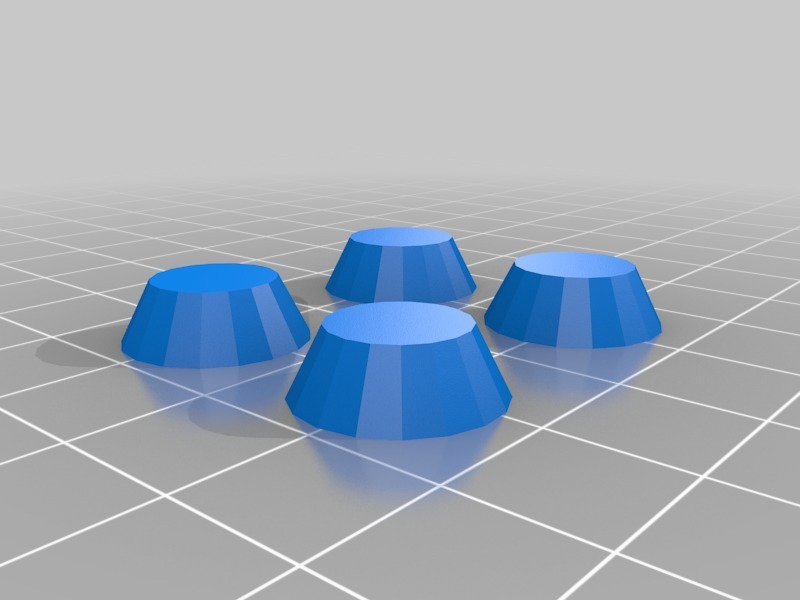

05-02-2017 add parts to fix the Arduino mega, power adapter and other device feets and cable clamps

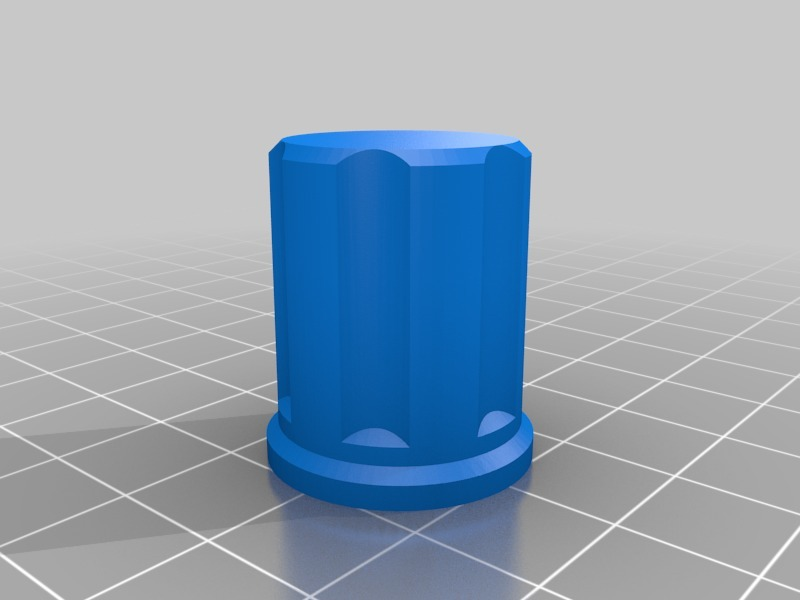

05-03-2017 add box for ampere and voltmeter and a knob. This things will be mounted on my power adapter for the hotwire.

05-05-2017 Power is nothing without control. Today I finished the hotwire power adapter. Up to 40 Volt and 4.5 Ampere... Enaugh power for a long bow.

05-10-2017 add left and right baseplate for mounting on the endstopp switches with M2 screws. The baseplates will be glued at the outersideside of the y-wagon. Where the energy chains take place. 4 rectangel parts will be glue or screw at motorhalter-y and x-wagon to trigger the switches in zero position.

05-13-2017 I finish the build. Last cables are in place. Little problems with software. The automatic calibration of origin failed. I am in discussion with the software designer to solve this problem. But the machine is ready now. Not longer a work in progress.

03-10-2019 If you had to change any parts of this thing you'll find the origin files, drawn by PTC-elements direct (free 3D software), here: https://www.rcgroups.com/forums/showthread.php?2858334-MPPCNCFC-3D-printed-4-axis-foam-cutter-hardware/page3 (links at #42)

or here: http://www.peterrausch.de/MPPCNCFC.zip

link to free version 3D software PTC Creo elements direct: https://www.ptc.com/en/products/cad/elements-direct/modeling/express

Feel free to build/print your own!

First test cut EPP: https://www.youtube.com/watch?v=Gn52ZY74V00

/https://fbi.cults3d.com/uploaders/29376852/illustration-file/27a3f829-4902-4ac2-a243-d2209869a101/20170520_125907_resize_20170520_153427.jpg)