Problem I wanted to solve :

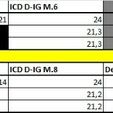

I had a Marui Hunter when I was young, and the idle gear was the weak point: it melted quite frequently. The Big Bear V1 and Super Wheelie used the same differential and had similar weak point with their idle gear, and even though it was made of some zamac alloy, it did not last long. The Big Bear V2 came with a strengthened transmission, with a reinforced differential and a different module (0.8 instead of 0.6 on the original transmission)

The way I did it:

I got lucky as a friend allowed me to put my hand on a V2 differential and to model it. And from then, I did work the interdistances between the diff, idle gear and motor pinion to deduct what was needed to get similar ratios (or closest possible) with the new module transmission

Once the parts were modeled, I tried with a full Nylon printed transmission in MJF PA12 (powder process with better characteristics than FDM prints for this type of parts, by an online printer), and although the diff works quite well, the idle gear did not survive a lap on a track on the Big Bear. On the Super Wheelie, it last longer, but after one pack it showed evident signs of wear. The Hunter one on ball bearing did survived as well, but even though the wear signs were less than on the Super Wheelie, I bet it would not have been survived. I finally printed the idle gears in metal using online printing service and got them running.

I did exhaustive testing on the Big Bear. I ran it for around 2 hours and half under Lipo 2S in various conditions, but always heavy on the motor load. I did check the transmission after that, and neither the Stainless Steel SLM Printed idle gear and the Nylon PA12 printed diff showed signs of wear. And the Big Bear being the hardest on those two parts, similar printed parts should be good for a Super Wheelie or a Hunter/Galaxy

You may find one video of the Big Bear run here : https://youtu.be/oaAtrkiP4cA

As many people asked me, I decided to find a way to propose the transmission sets. I've looked at the options, and the only I could find with a market place available were either way too expensive, either did not proposed all the needed printing process for this. I printed my final parts using JLCPCB (China) and the prices were really interesting, even with shipping and taxes included (I've included some screenshots of the prices so you can see as well the options I used for the prints).

Printing your transmission set

I've included 3 types of files in this publications. The start of the filename is linked with the process to be used for the print:

- SLM : The Idle gears are targeted for prints in Stainless Steel SLM 316L and I have printed those files thru JLCPCB. You may use them somewhere else, but I can't say about the results. I've printed at least two of each of the SLM idle gears with JLCPCB with consistent results

- MJF : the clustered diff is targeted for prints in MJF PA12 (powder based process) . I've print this file thru JLCPCB again, 4 times with consistent results.

- FDM : if you have access to a printer on which you can print Nylon PA12 (enclosed, with a good quality), you may print the diff using those file. It is not an easy prints, as some parts require support, and therefore MJF is much better than FDM. But I have printed the bevel gears on my Bambu Lab during the testing process and they are still alive on one the test cars. So up to you if you want to do this...

Differential Assembly

Compared to the original Marui differential, this one has 3 small bevel gears, instead of the 2 originals bevel gears included in the original diff. You will need 3 4x11.5 bevel shafts instead of 2.

M.08 Motor Pinions

You will need new motor pinions, preferably in Stainless steel, as Aluminium may wear quite fast. Here is the different Pinions you need depending on the car you build

- Big Bear : Pinion module 0.8/32dp 11T

- Super Wheelie : Pinion module 0.8/32dp 14T

- Hunter/Galaxy/Galaxy RS : Pinions module 0.8/32dp 12T, 13T or 14T (11T and 15T maybe possible, but I've not tried)

Additional notice

- I have tested this in multiple configuration. I did it in a way where you can just shave a bit of the bevel bushing on the sides to increase the play if needed, either on the diff side, or on the wheel side. I took this approach as not everyone has a printer at home and would be able to print a 0.1mm or 0.2mm parts that goes between the bevel gear and the bevel bushing.

- the Hunter/Galaxy idle gear has room for 2 ball bearings 693RS 3x8x4. The original idle shaft corresponds to a slightly larger diameter (3.125mm) and will need to get shaved or replaced by a 3mm shaft of the same length. You may need a press to fit the ball bearing on the bigger side. Doing it differently would make the ball bearing too loose in the cage. V3 is technically identical to the V2, but I added holes in the design to make it slightly lighter (V1 was replaced by V2 because it requires more clearance for the diff and the design was adapted for this).

Why I put a price tag on this?

Let me explain :

- First, it is months of work, and it costed me quite a few bucks to get the prints I needed to achieve this (more than you can imagine, as there was multiple version to achieve this).

- Second, I saw many downloads of all the parts I put on Thingiverse, here and Printables, but only very few contributions, and more, I saw people taking benefits of printed parts to resell repaired cars a fortune (and clearly much more than what they paid for them in first place), and this was not exactly what I hoped by supplyng the files of the cars I provided : the overall idea was to allow people to repair them to run them.

- Third, the price for the file and the prices of the prints should cost you way less than a full set of original parts very difficult to find nowadays

Thanks to have read up to now. Hope to see your Marui 2WD cars running happily soon :-)

/https://fbi.cults3d.com/uploaders/18599880/illustration-file/13696712-0479-42cc-80bf-8f06deebde64/Pics-Marui2WD-TransmissionSet.jpg)