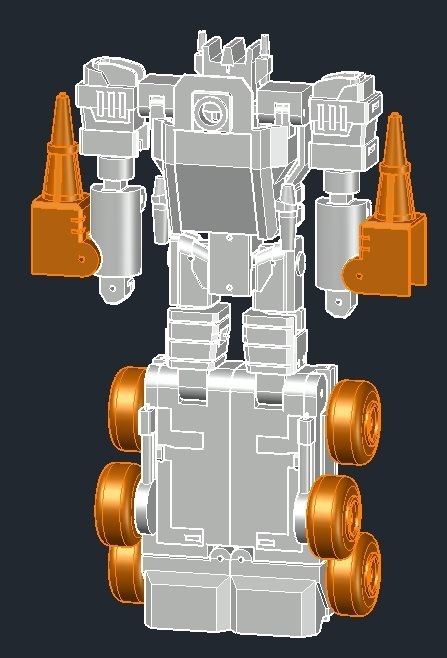

3D model description

I am a beginner and this is my third and my first! transformable 3D model design.

Scorponok's Fasttrack in legends scale based on an picture of Jizaitoy's Fasttrack. That Fasttrack is never released, i liked this model very much, so i desided to try to make this design fully transformable. Now my Iron Factory Scorponok has his buddy to play with! :)

The height of Fasttrack is around 11-12cm.

Its articulated

Head: left and right rotation joint

Arms: balljoint in shoulder, swivle and rotation joint in elbow

Body: hip rotation

Legs: Thighs joint + rotation, Knee rotation, Ankels articulated, Feet rotation

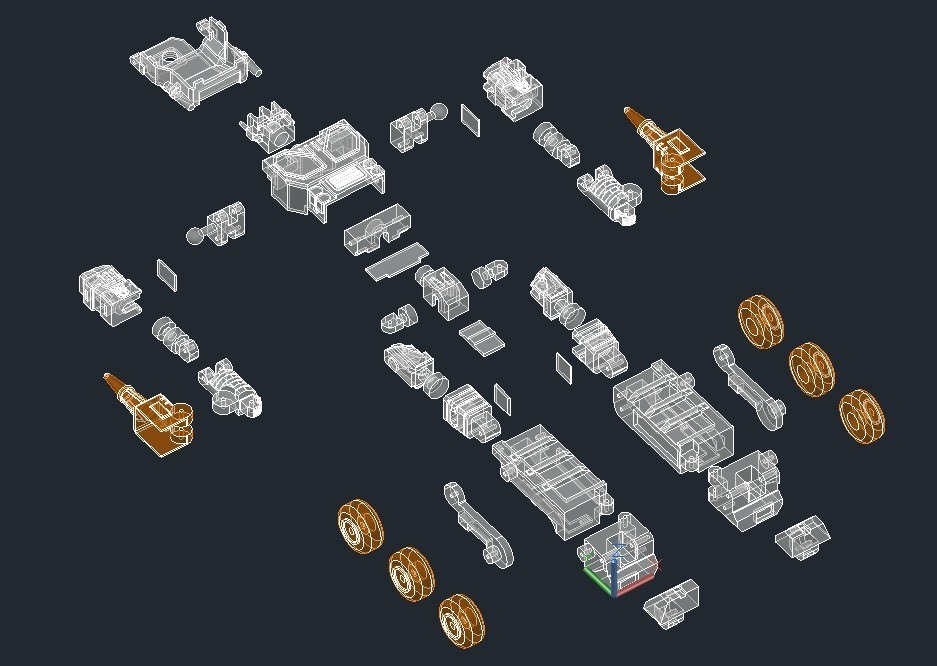

Some extra information for assemble, PLEASE READ!.

-Joints are made with filament 1.85mm

-All joints are tight fit. Mostly no adjustment. But you do need a cutter/sandingstick to adjust if needed.

TIP: The bal joint of the shoulder piece is tight. So sand a little and try to push it in the upper arm. If it does nog go, do not force, Sand a little more until it goes is. Then slowly try to rotate. If it does not rotate, you can remove the balljoint and sand a bit more, and try again until it rotates without harming the balljoint handle.

-I made extra small cap plates for the swivle joints in the arms and legs. This can be glued on the parts to prevent the swivle joint coming out the joint. (if tight joint, not needed)

-extra plate for glue on the back of the hip, to prevent the hip joint coming out.

-I printed pre-drill holes in the model where filament is needed. Drill this with: 1.7mm or 1.8mm drill for tight joint

-For the transformation i made ready made holes (drill afterwards to 1.7mm diameter) in (1x) the lowerleg and (1x) in the ankels. You can put a piece filament on 1 side to made a connection when transforming to alt mode, this will prevent the legs staying loose and holds the legs together)

Remarks drilling:

Feet-ankles: drill 1.8mm + filament

Ankels-lowerlegs: drill 1.8mm

Wheels: drill 1.7mm in axle (lowerlegs+ankels). The wheels 2.0mm for rotation. Make a rivet in the filament with a lighter to prevent the wheels falling out.

Lowerleg-Knee-wheelflip: drill 1.8mm. Drill 1.7mm in wheelflip for tight joint.

Knee-tighs: drill 1.8mm

Thighs-hip joint: drill 1.8mm

Midsection-chest: drill 1.7mm in midsection, 1.8mm in chest

Chest-shoulder: drill 1.8mm (try to drill in steps of 1.0-1.5-1.8mm to prevent bracking the joint)

Shoulder-back: drill 1.8mm (try to drill in steps of 1.0-1.5-1.8mm to prevent braking the joint)

Elbow-fist arm: drill 1.8mm

Please drill this accordingly to filament diameter.

Tools:

Drill 1.7-1.8-2.0mm (recommended 1.0-1.5mm to pre drill to actual needed size)

Cutter

Sand paper/stick for tolerance adjustment

Instant glue

Filament 1.75mm

Lighter (to make rivets with filament)

If any question? please ask.

Please comment or let me know how you like it.

3D printing settings

Slicer: Cura

Filament: PETG / PLA/ PLA+ 1.75mm

Printer: Easythreed

Height 0.15mm

Print orientation: accordingly my best, please try otherwise

/https://fbi.cults3d.com/uploaders/27368747/illustration-file/63be22f2-610c-47ce-be2b-2358509f4026/Fasttrack5.jpg)