3D model description

This model was originally the first one I designed for this collection. This cute cat is my take on the traditional lucky cats and has a fully functional waving arm. Tap its head and it will wave at you for up to 1-2 minutes (depending on the material you're printing with).

The rectangular coin is printed separately so you can choose to add it or not. This also makes it a lot easier to print and you can just choose a different filament or paint it. If you want, you can attach it to the cat's body with a small drop of glue, or just place it loosely against its tail.

As with all my designs, I went through multiple iterations to perfect the mechanism and the printability of the model without any support structures. All you need is a good bed adhesion and good cooling for some clean overhangs.

No assembly is required!

The integrated compliant mechanism and printed spring allow for a frictionless design with big tolerances which should make it possible to print this on almost any FDM printer. SLA might work as well although it is not specifically designed for it.

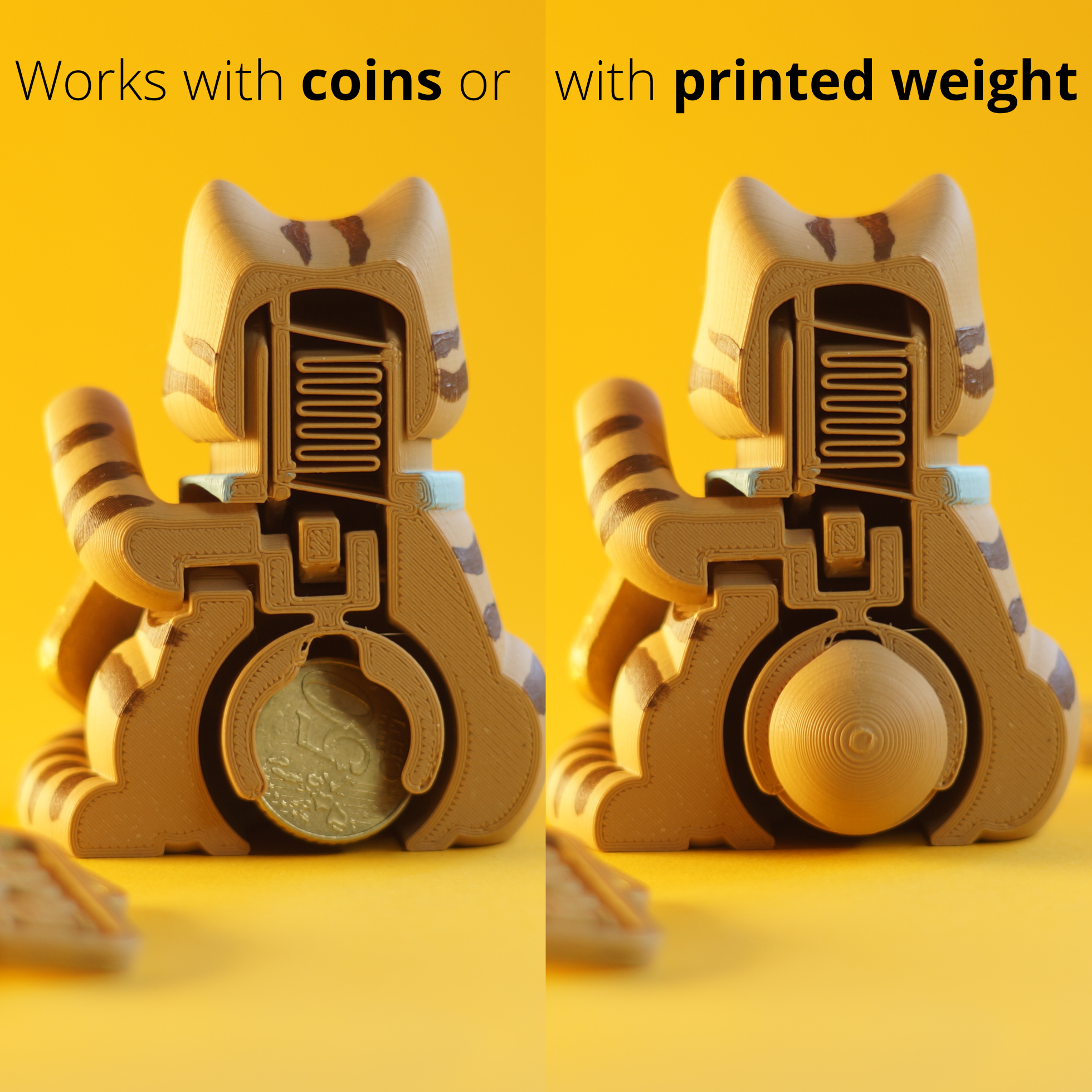

This model can hold coins within a size of 23 – 26 mm (0,9 - 1,02 inches) which makes this model great as a coin saver for shopping cars. Alternatively, a printed weight can also be inserted.

It’s also fun to put the model on your car's dashboard as it will start waving in sync with the movement of your car while driving.

3D printing settings

IMPORTANT: Make sure that the springs will be printed by checking the slicer preview. Here are some slicer-specific settings to make sure that the spring will turn out correctly.

For all Slicers

I would not use a brim for the bed adhesion as it will be hard to remove from the spring.

Prusa Slicer

Print Settings > Advanced > Slicing > Slice gap closing radius > set the value to 0 mm

(If you are using a version older than PrusaSlicer 2.5 go to Print Settings >Layers and perimeters > Quality > Detect thin walls > activate it)

Ultimaker Cura

No special settings required

(If you are using a version older than Cura 5.0 go to Walls > Print Thin Walls > activate it)

Bambu Slicer

(Advanced settings > Quality > Precision > Slice gap closing radius > Set to 0 mm

(Advanced settings > Strength > Walls > Detect thin walls > Activate

General settings

This model is designed for a 0.4 mm nozzle/linewidth. If you have a bigger or smaller nozzle installed on your printer I recommend you scale the model up or down accordingly:

0.3 mm Nozzle => 75 % Scale

0.4 mm Nozzle => 100 % Scale

0.5 mm Nozzle => 125 % Scale

0.6 mm Nozzle => 150 % Scale

0.7 mm Nozzle => 175 % Scale

The model is designed to be printed on its back as it comes with the file. Printing in any other orientation will cause the springs to fail.

Supportfree design. No support is required.

A good print bed adhesion will guarantee a successful print, so make sure everything is properly-leveled and maybe apply a spray adhesive if your filament requires that.

At 100% scale, it prints in roughly 5 hours with 50 g of material.

Set the cooling to a high value.

Be careful when removing the model from the build plate.

If you have any issues with stringing its best to remove the strings by hand to increase the swing time of the pendulum.

Happy printing!

/https://fbi.cults3d.com/uploaders/26427977/illustration-file/6099c1d8-51c0-4482-aa6f-b10e4faaa98e/Thumb1.gif)