3D model description

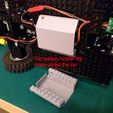

I designed these parts to make my old 1985 "brick" Technic 8860 car run and steer by remote control. The goal was to have a completely running car without any visible added on parts when looking at the car from above. I wanted it to look original when running.

Here's a video of it running:

https://youtu.be/TM9aZgGp-TE

It's not fast but it's driveable on smooth floor in second gear and will run on carpet in first gear. I will post a video soon when I take it to the track. The steering is very good. The plastic drive train can't handle a powerful setup so I selected this motor for its low torque so as to be gentle with the plastic axles and universal joints. Don't expect a race car.

I use a 3S 450 mAh lipo to power it and this battery fits in the little battery holder underneath the car. You can use bigger 3S batteries if you make your own mount, off course. The car draws very little current. I suppose a 4S battery can be used for some more speed but I havent tried it as my ESC can't handle more than 3S.

The 1:2 gear ratio setup is for 1800 rpm motor and this is what I used on mine since that's the motor I have. The 1:1 gear ratio can be used with a slower motor, like the 830 rpm variant if you have one lying around. The 1800 rpm motor doesn't have enough torque to use the 1:1 ratio (I tried this first).

If in doubt figure it out. These brick models are all about figuring things out.

File list:

8860-Batteryholder.stl - Holder that fits under the chassis.

8860-gear05.stl - 16t spur gear for two 3x6x2,5mm ball bearings.

8860-gear06.stl - 16t pinion for 1:1 drive.

8860-gear07.stl - servo gear for the steering with Corona servo.

8860-gear08.stl - 8t pinion for 1:1 drive.

8860-gear09.stl - servo gear for the steering with Emax servo.

8860-Motormount1-1.stl - 1:1 ratio motor mount and gear box for mounting underneath the boxing engine of the car.

8860-Motormount1-2.stl - 1:2 ratio motor mount and gear box for mounting underneath the boxing engine of the car.

8860-Steeringbox01.stl - Bottom part of the front "fuel tank" with mounting lugs for a servo.

8860-Steeringbox02.stl - Middle part of the front "fuel tank" with room for a receiver and a guide hole for the steering axle.

8860-Steeringbox03.stl - Top lid for the front "fuel tank."

Bill of materials (affiliate links where applicable):

1x Corona 843-MG servo is recommended (or similar with the exact same dimensions). Emax 3301, 3302, 3351 or 3352 should also fit.

1x small 3S ESC .

1x Transmitter and receiver of your choice.

1x 3S 450 mAh lipo with smaller than 16x33 mm crossection.

1x 12V JGA25-310 DC Gearmotor with 1800 rpm: https://ebay.us/dtXJf1

2x 3x6x2,5 ball bearings: https://www.ebay.com/sch/i.html?_nkw=3x6x2

1x M3x12 screw for the spur gear.

2x M3x8 countersunk screws for mounting the motor.

2x M2,5x5 countersunk screws are ideal for the servo mount, but typical self tapping screws can be used.

3D printing settings

Four 0,4 mm perimeters and 10% infill 4 bottom and 6 top layers works well.

PLA is fine.

If the gears have gaps when slicing then your settings have a too wide extrusion width.

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/51f20e8d-c738-4e14-a3c9-6fed99d3a4ac/8860-01.jpg)