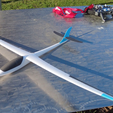

Lukisegler-NG XS e Mini RC electric glider with brushless drive

Span: approx. 900 mm

Hull length: approx. 500 mm

Take-off weight (LW-PLA, electric glider): approx. 120 g

Functions: Altitude / bank / motor

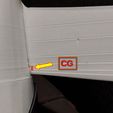

Center of gravity: 8 mm behind the wing nose on the fuselage

Rudder deflections:

Aileron: 15-25°, EXPO-setting: -10% for direct response

Pendulum elevator: 10°, EXPO-setting: 20%

Motor: BETAFPV 1103 11000KV brushless motor

ESC: 12A brushless ESC

Propeller: 65mm (drone propeller)

Battery: 2s Lipo 250 mAh

The challenge with this model was to build the smallest possible glider that could be created with a standard 3D printer and controlled with a conventional RC system.

It is printed in LW-PLA.

Other parts are carbon rods, steel wire, some small screws and the RC system consisting of two 4.5 gram servos, receiver and the Lipo battery.

The ready-to-fly model weighs less than 100 grams as a glider. The electric version has a take-off weight of 120 grams.

A video of the construction and first flight is available on YouTube:

YouTube: Construction and first flight of the Lukisegler-NG XS

A video of the first flight of the electric glider version is available on YouTube:

YouTube: First flight of the Lukisegler-NG XS e

A complete playlist with building instruction videos is available on YouTube:

Lukisegler-NG XS e construction instruction videos

The files also contain short assembly instructions that go into some more details.

If you decide to build the model, I would be happy to receive a short report on your experience in the comments or you can contact me via the Cults Messenger.

This would help me a lot to improve the design of my new models or to fix bugs in the current models.

Modifiers in PrusaSlicer are used in the print files. These are essential for the stability and structure of the individual parts! The adhesive surfaces for connecting the individual parts are created with the help of modifiers.

Parts required for the assembly

Carbon rods or fiberglass rods and various adhesives are required for the body.

Adhesives:

Superglue, low to medium viscosity

Carbon rods:

Carbon rod 1 mm: 3 pieces (450 mm length)

Carbon rod 1 mm: 1 piece (180 mm length)

Carbon rod 1 mm: 1 piece (820 mm length)

Carbon rod 1 mm: 1 piece (540 mm length)

Carbon rod 1 mm: 1 piece (100 mm length)

Carbon rod 2 mm: 1 piece (100 mm length)

For the elevator pushrod:

Carbon rod 1.5mm (500mm length)

The carbon rod for the elevator linkage must be shortened to the appropriate length according to the servo used. The 500mm should only be seen as a rough guide.

Steel wire

Steel wire 0.6 mm: 2 pieces (approx. 400 mm length)

Screws

Wood screws 2x10 mm (d x h): 2 pieces

Tapping screws 1x6 mm (d x h): 2 pieces

Electronic components

Servos

Micro (4.6g) servos: 2 pieces

Receiver

Minimum: 2 channels or 3 channels for the electric version

Installation of the electric motor

CAUTION never run the brushless motor at full throttle without load* if the ESC does not catch the correct commutation time, the motor may be damaged by overcurrent*.

I also added a motor cowl and a spinner for the propeller.

The cowl is glued to the fuselage and adjusted to the engine height.

The spinner is attached to the motor axle. The propeller is then attached to the axle.