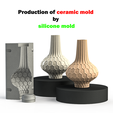

3D model description

Please read the description in full

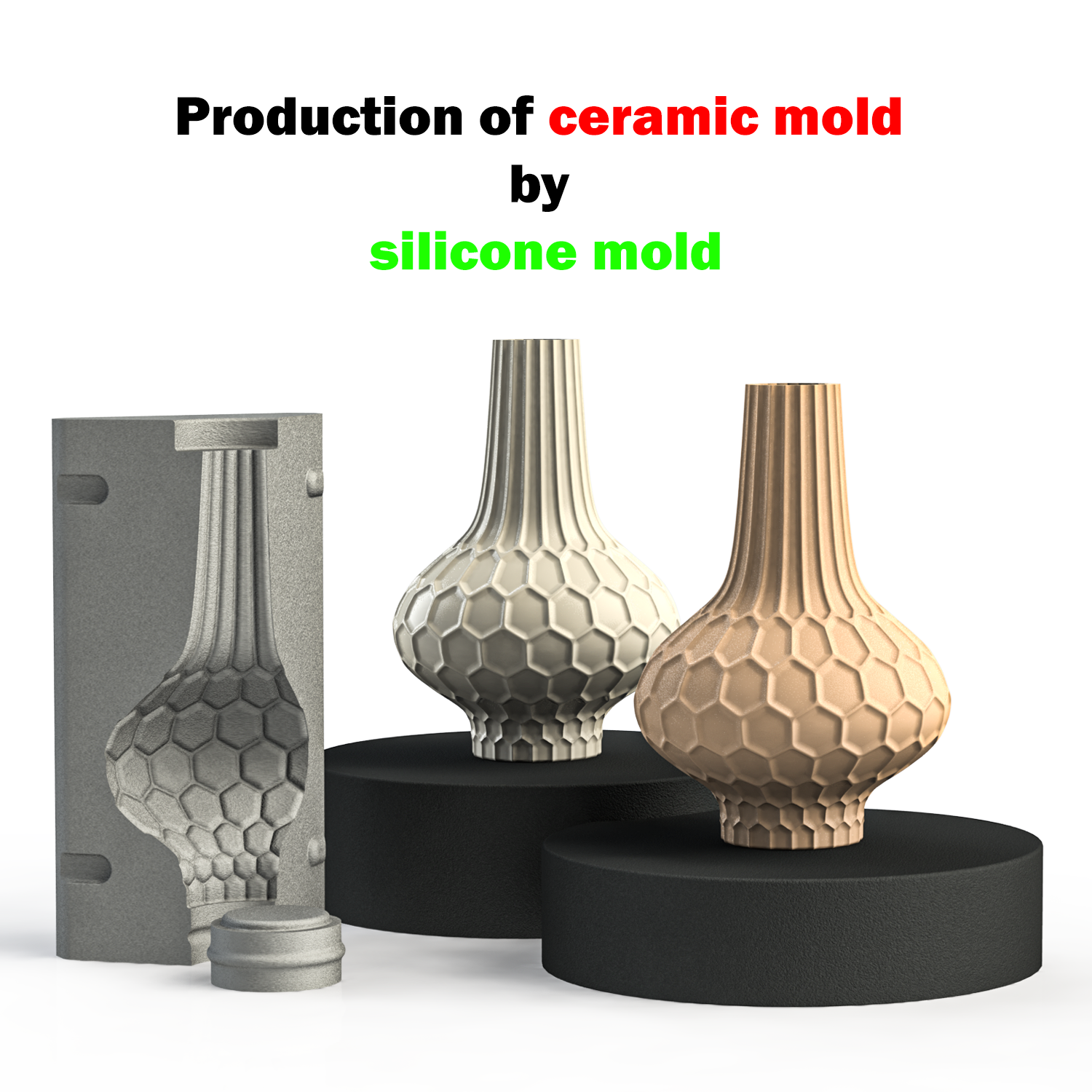

Ceramic manufacturers know very well that they have many challenges to buy plaster molds for the production of ceramic products. For example, it is possible that the molds are damaged during shipping, or that they have to produce only products whose molds are available in the market, and if they want to produce a specific product, they have to spend a lot of money on making molds.

The method we use to make the molds used in the production of ceramic products solves all these problems. You don't need to wait for the mold to reach you from another city or country, but immediately after purchasing this product, all the files needed to make a suitable mold will be in your hands.

Now, if you want to know more about this type of mold, read the description below :

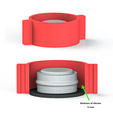

As it has been said in the pictures, according to the research conducted by ceramic factories, the amount of shrinkage of the product after it comes out of the kiln is about 14%. So, you need to know that the product output from the molds is 14% larger than the original dimensions

Try to use silicones that do not have high flexibility to make a silicone mold. The product is designed in such a way that it is easily removed from the mold, and if the silicone used is highly flexible, it is possible for the molds to be deformed and not assembled well. My suggestion is to use RTV2 silicone with low flexibility, but you can use any silicone that is available in your area.

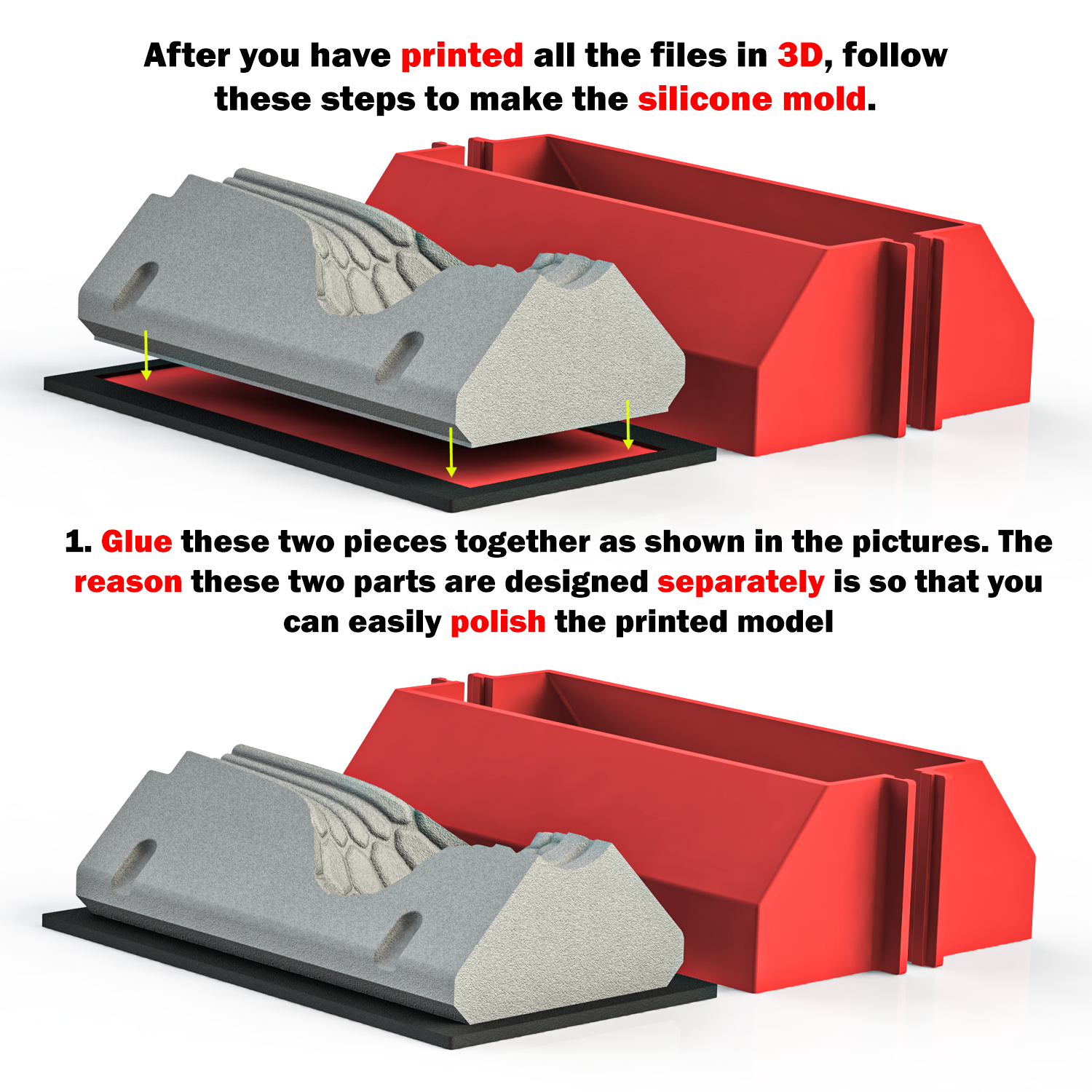

The best way to make models is to use printers with SLA technology, but due to the high costs of making models using these printers, you can use printers with FDM technology or conventional printers that work with filament. If you don't have a printer yourself, you can give the files to someone who offers 3D printing services and ask them to make the models for you. Make sure that the dimensions are made correctly and according to the dimensions presented in the pictures.

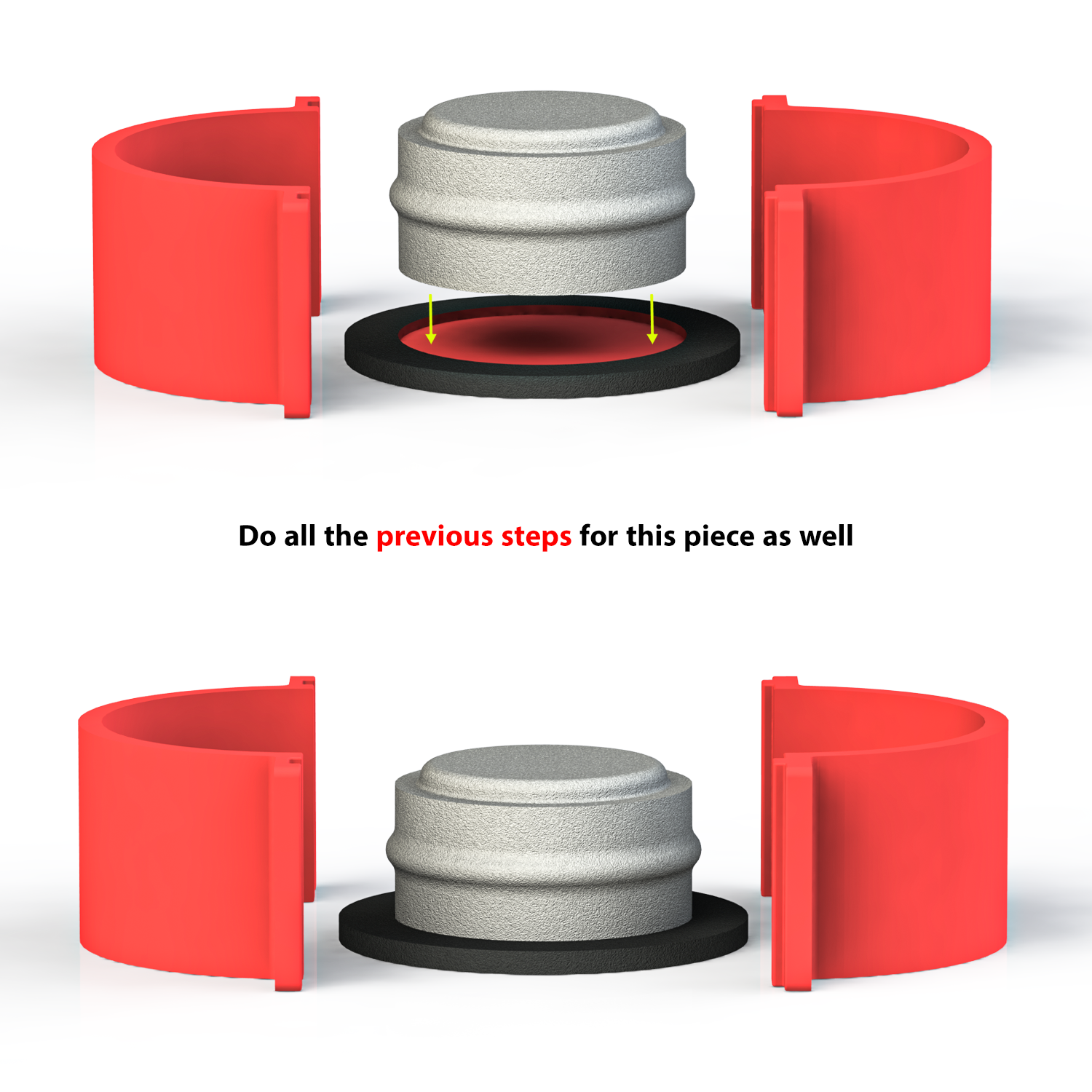

This mold contains 5 pieces, you only need two silicone molds to produce these 5 pieces. One mold to produce 4 large parts and one mold to produce the small part

After making the models by 3D printer, you need to polish them. But be very careful about the fact that you are going to produce 4 sides of the plaster mold from the same silicone mold, so if you polish the models too much before making the silicone mold, their dimensions may change and the plaster molds will not work well. Just try to fix the model flaws if there are any and do the main polishing once you have produced the plaster molds as plaster molds are much easier to polish than 3D printed casts.

You can add your logo to the bottom of this model

In the description, I tried to explain the points that were needed to use these molds. If you still have questions, you can contact me

This is a digital product and after purchasing the files needed to make this mold will be provided to you

my Email : saeedkhodayari.net@gmail.com

3D printing settings

If you need help with print settings, send me an email so that I can help you as soon as possible

/https://fbi.cults3d.com/uploaders/15822215/illustration-file/97a32a7a-d895-4b66-b470-d69d9ee04d98/poster.png)