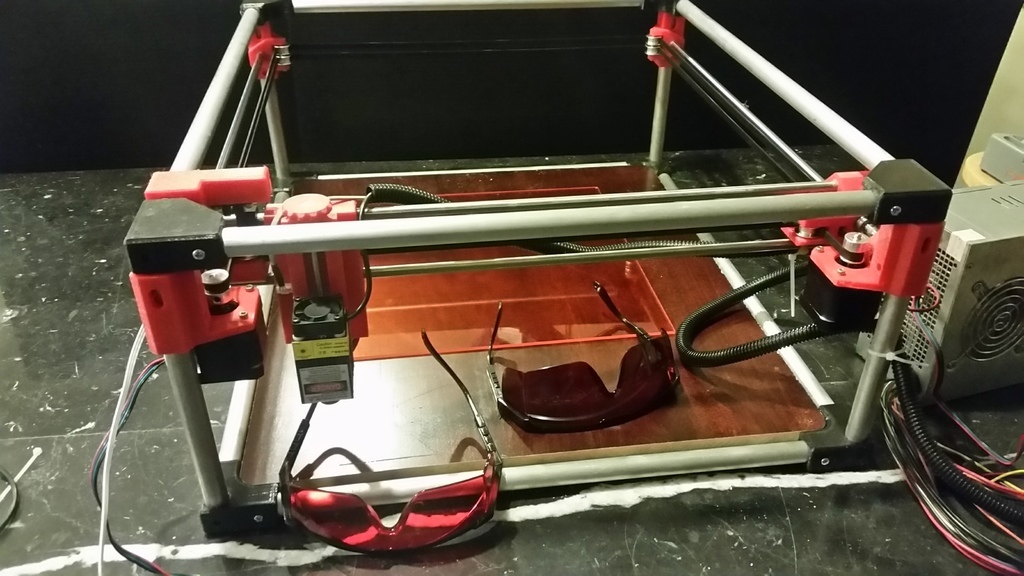

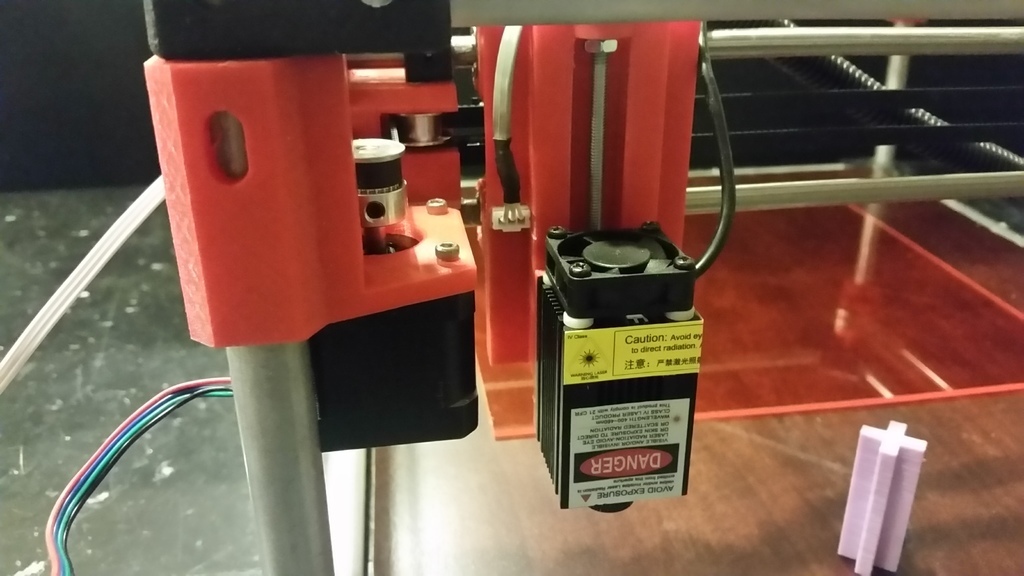

WARNING: These lasers are not toys and they will hurt you! Make sure you wear eye protection when using them! PLEASE read this for more information.

Update 3/15/2018

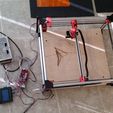

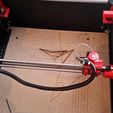

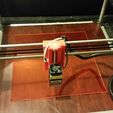

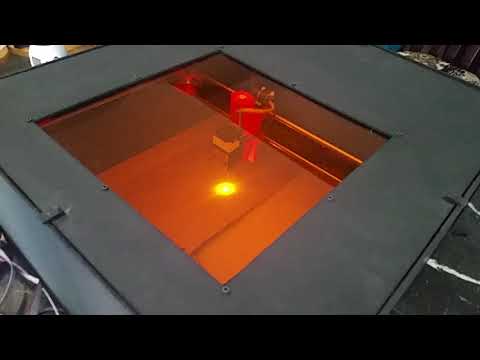

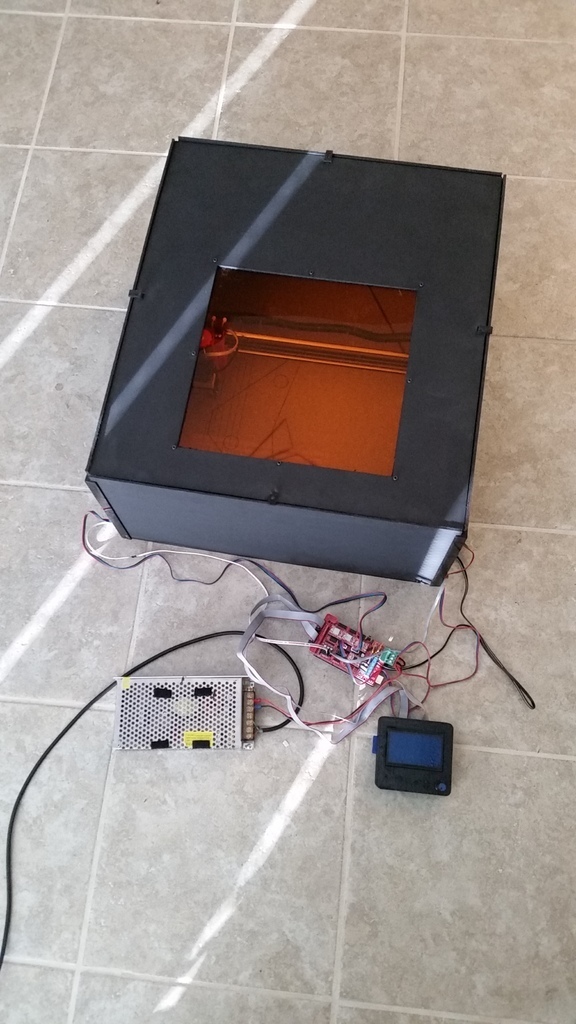

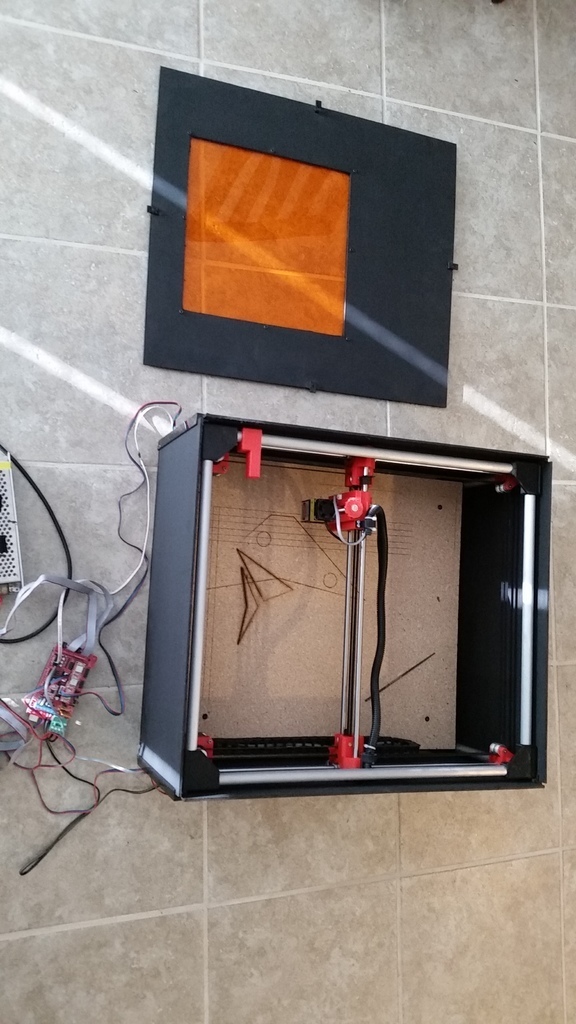

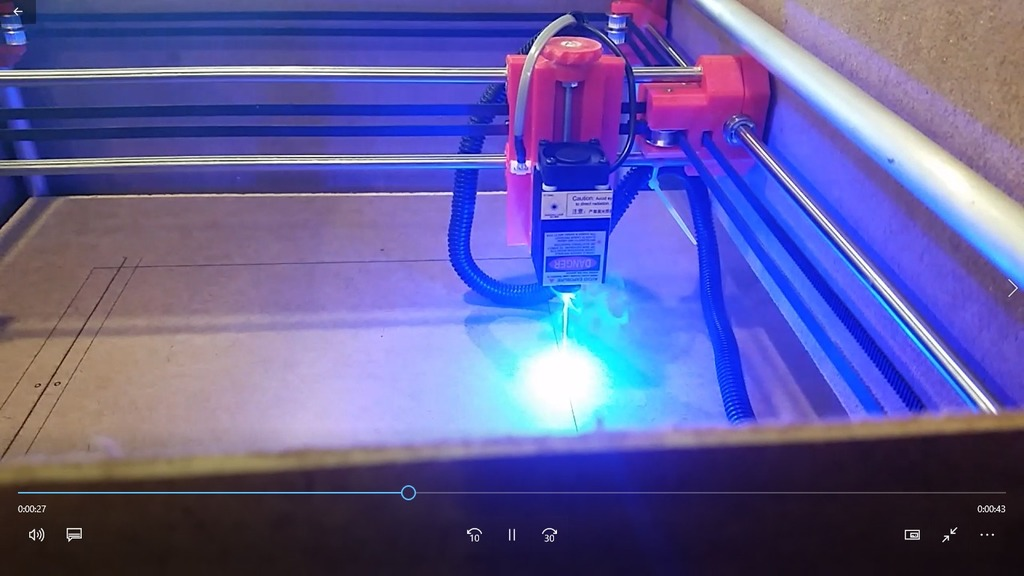

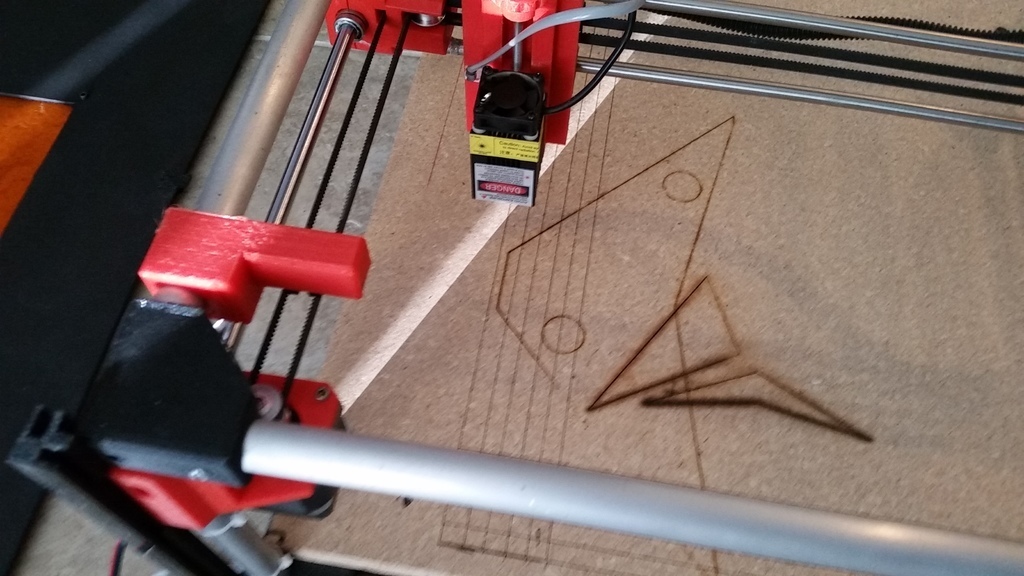

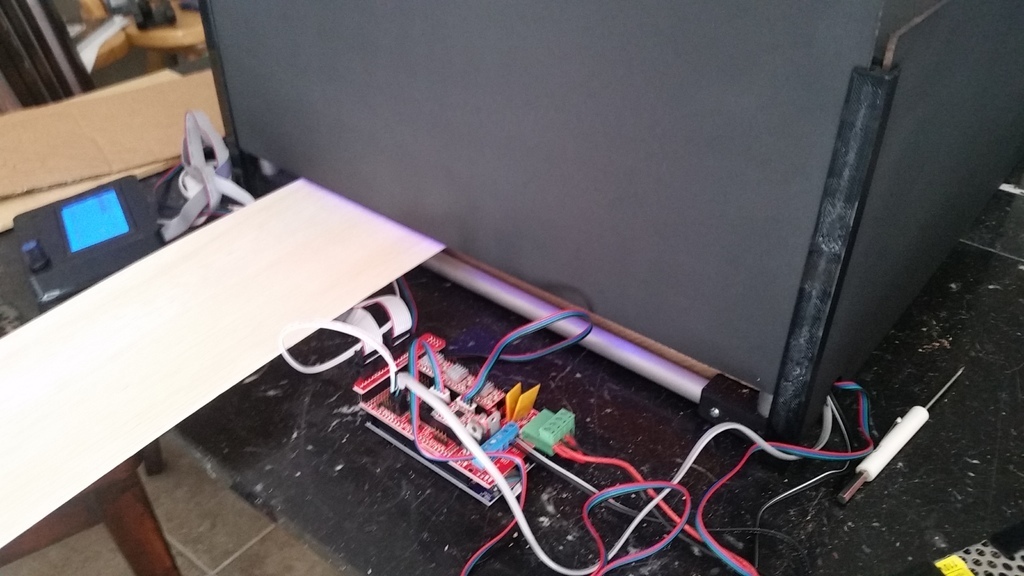

It's time to call this one done. Spring/Summer is coming and it's time to get back to my other hobby (USPSA/IPSC). I've posted some final pictures although I didn't create a mount for the RAMPS/LCD. I did buy a GRBL CNC shield and I may use that instead in the future (NOTE: if you buy the v4, you have side load the UNO boot loader onto the NANO, otherwise it will not run the CoreXY setup... not enough space). Here is a video of a sample cut on some cardboard.

Enjoy,

Triggermeister

P.S. I do think it would be fun to convert a CTC i3 or ANET A8 into a Tube Cube 3d printer by using as many parts as possible an buying the least amount of materials. I think that would be game changer...

Update 2/28/2018

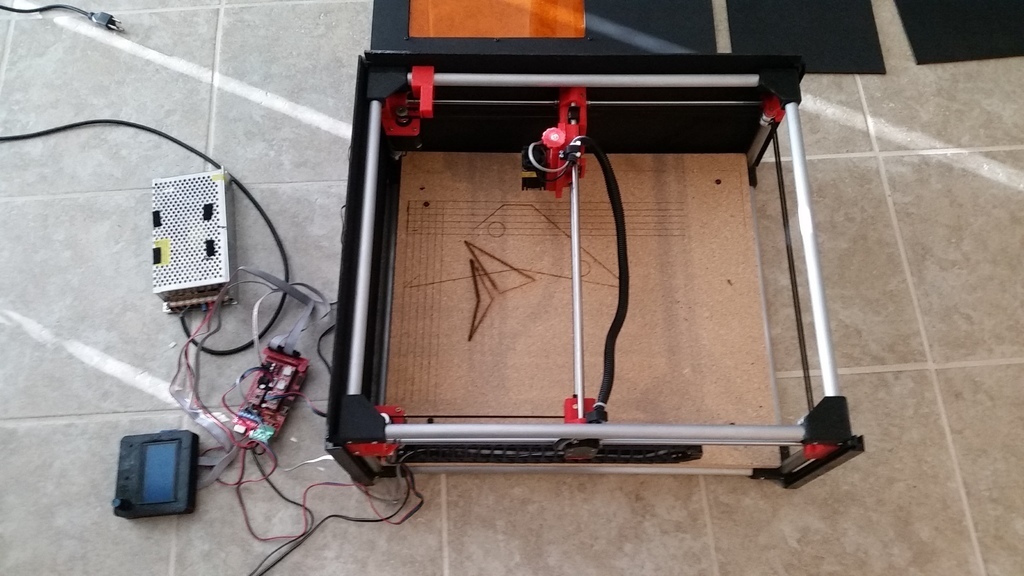

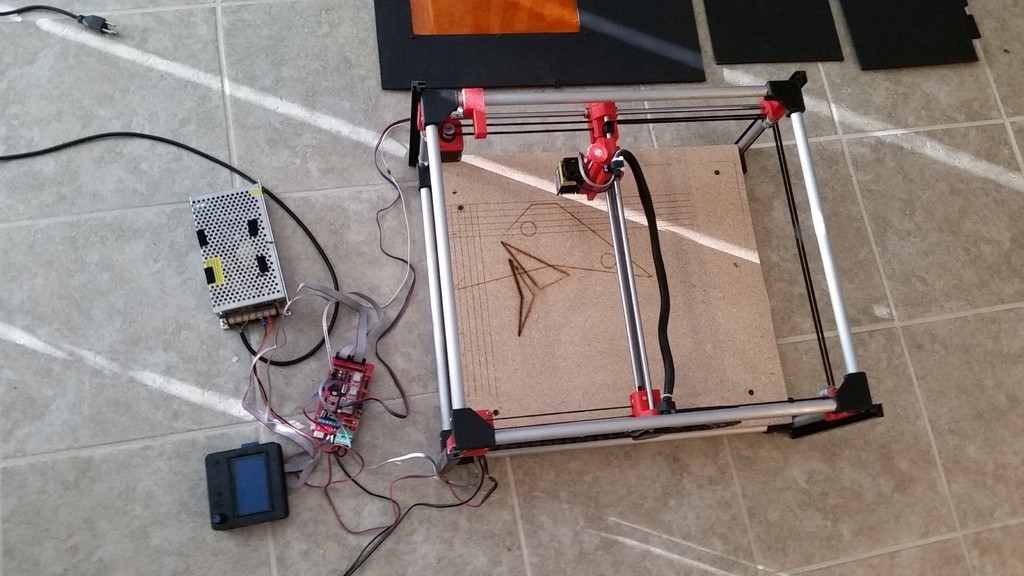

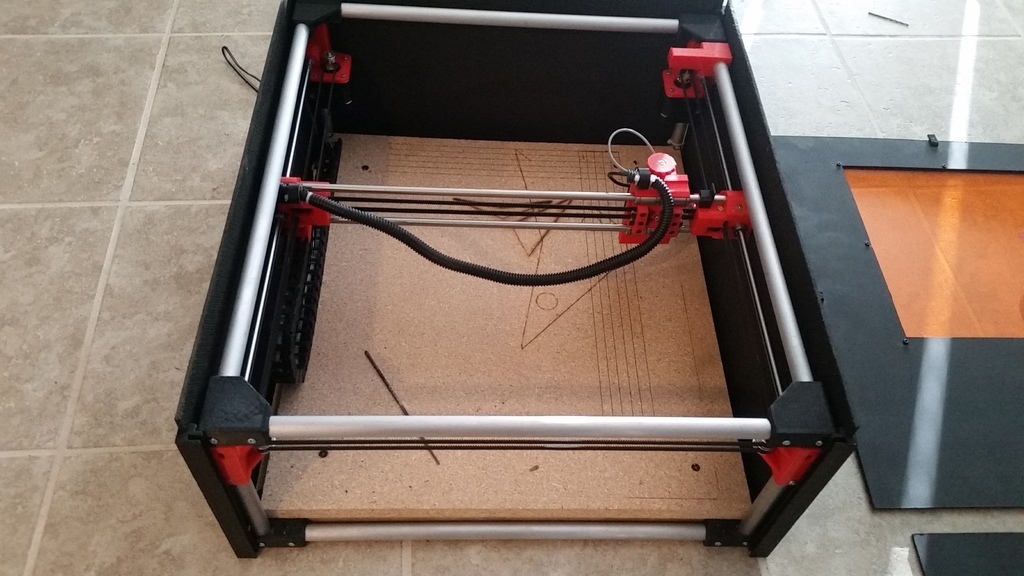

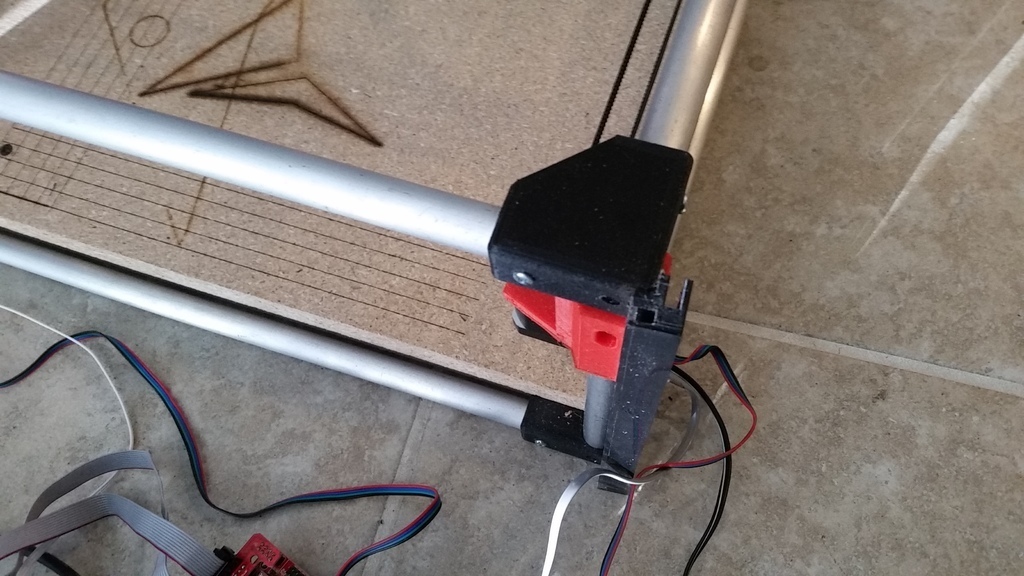

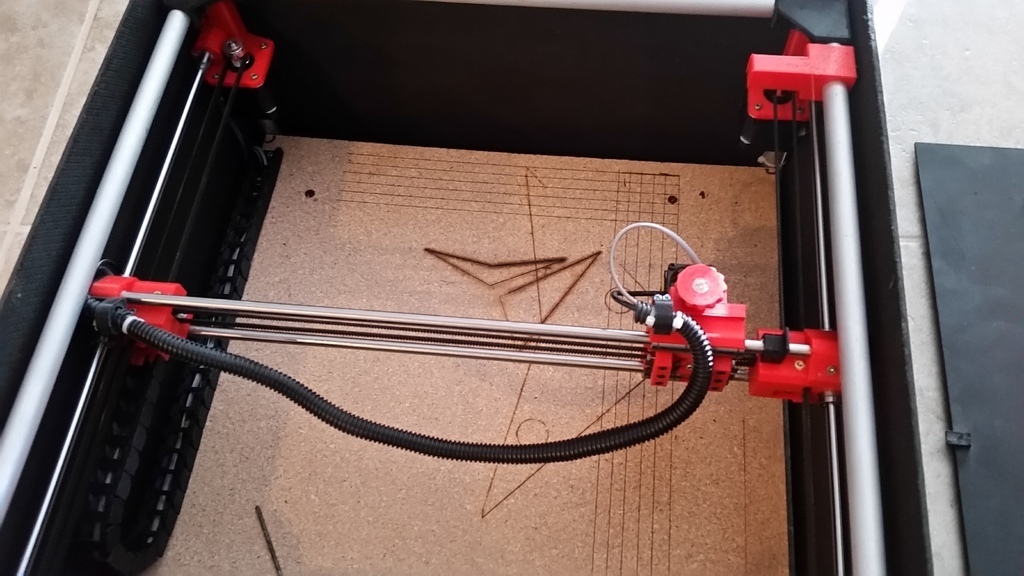

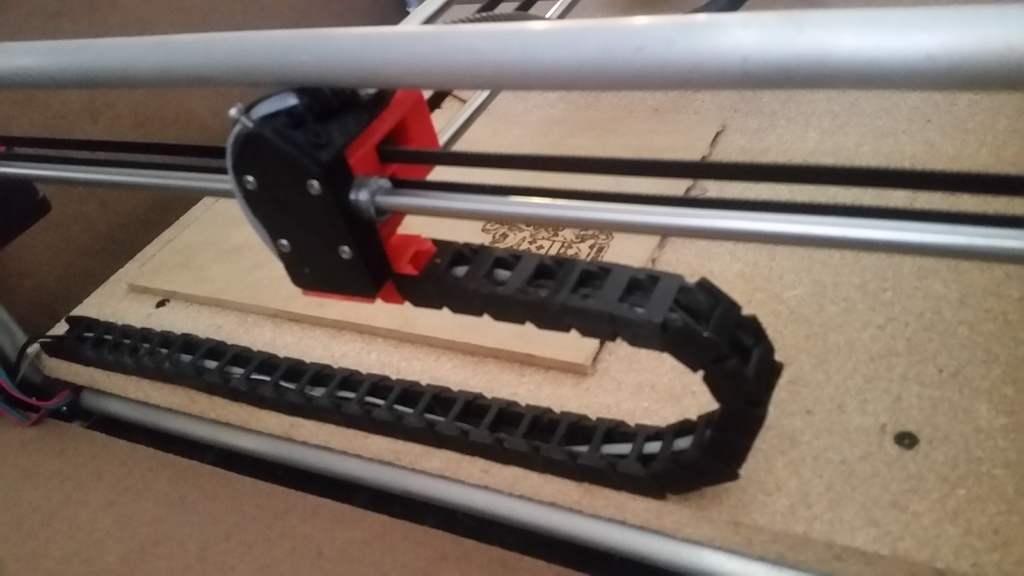

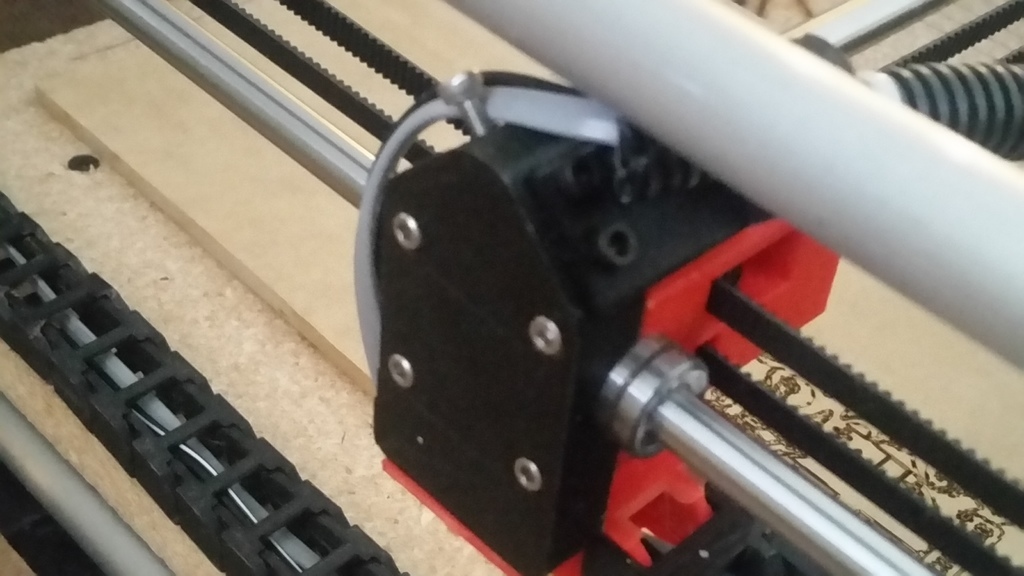

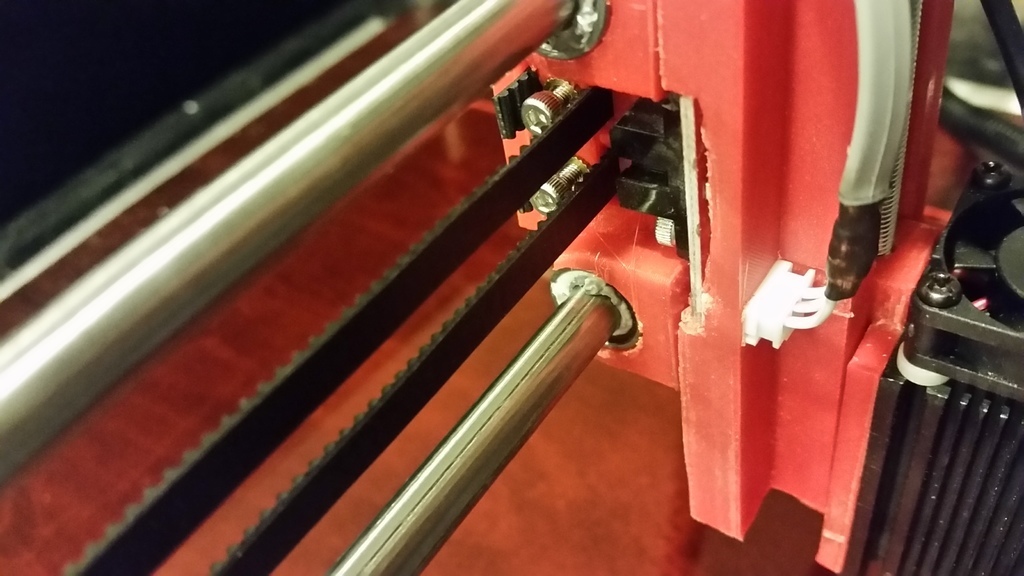

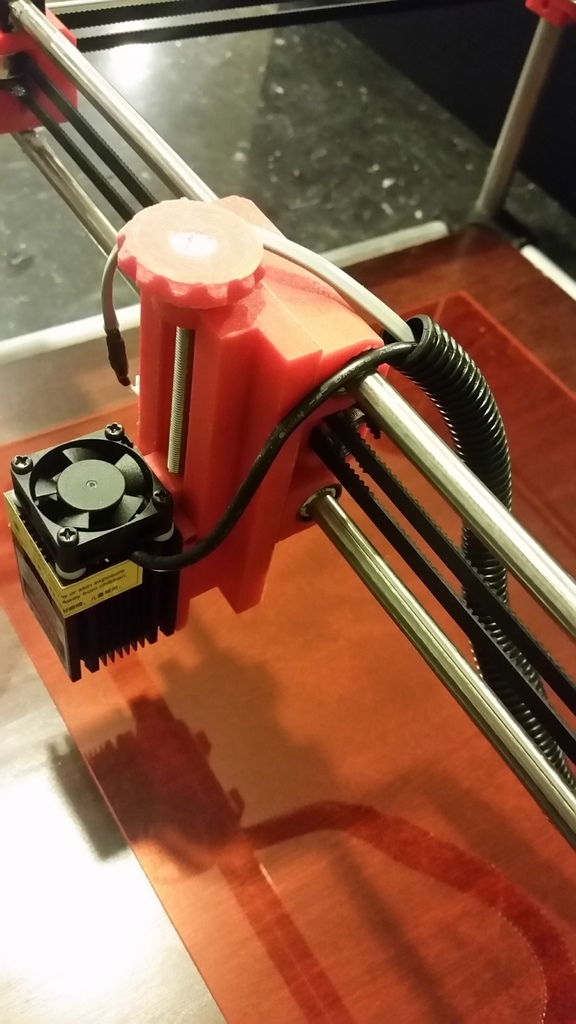

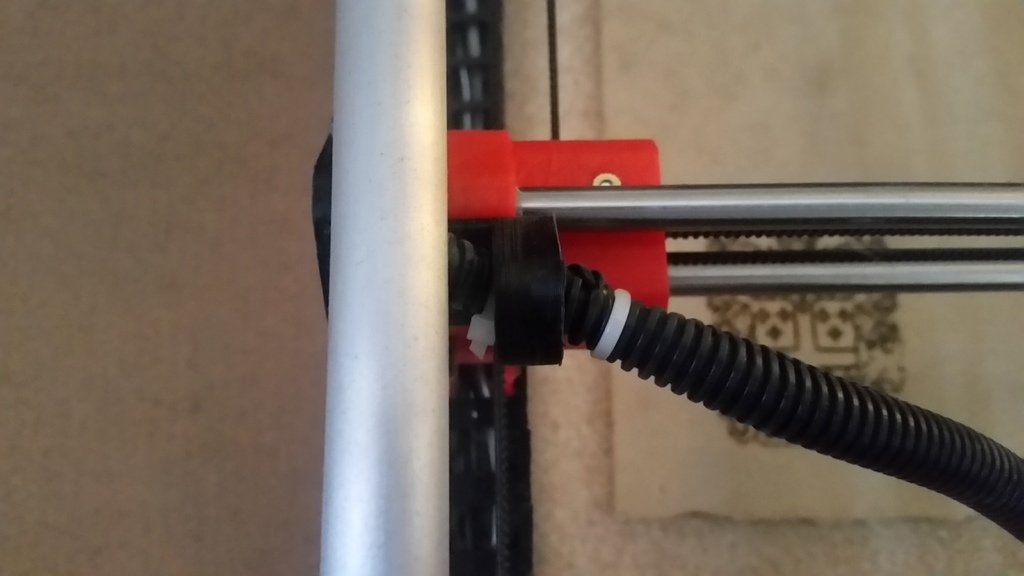

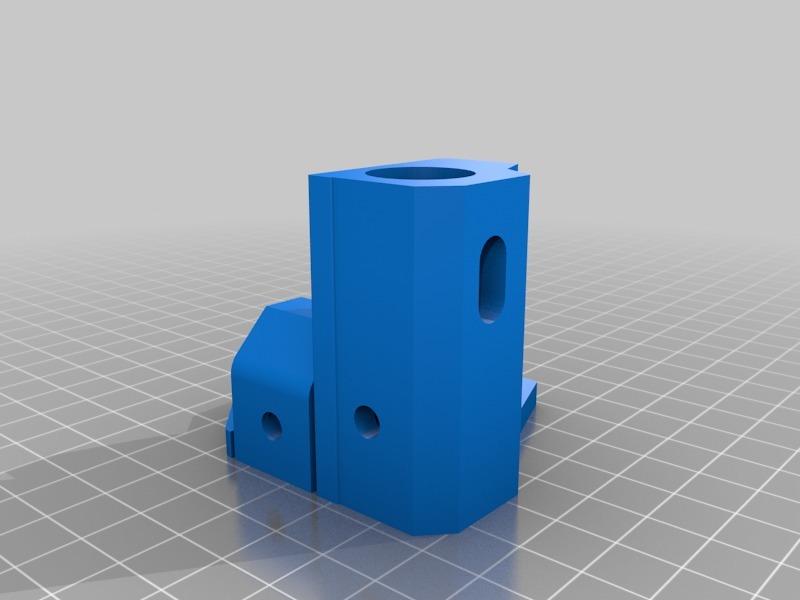

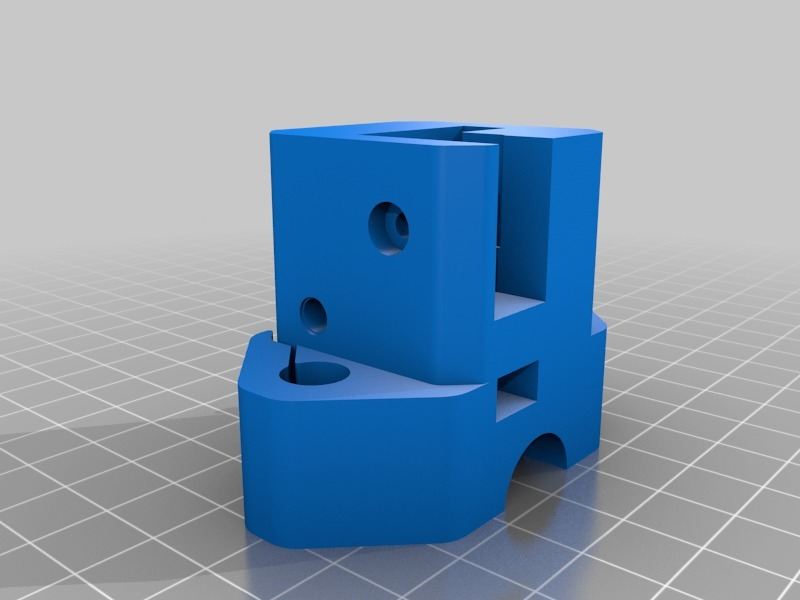

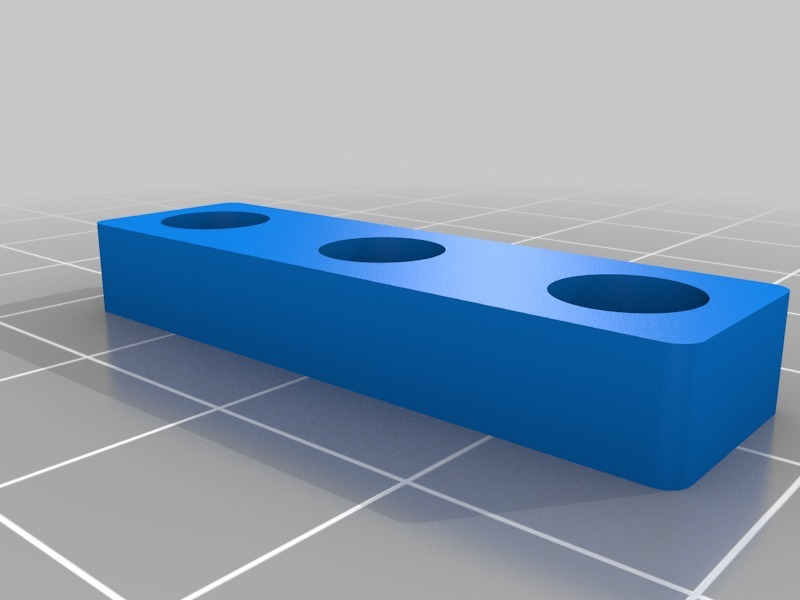

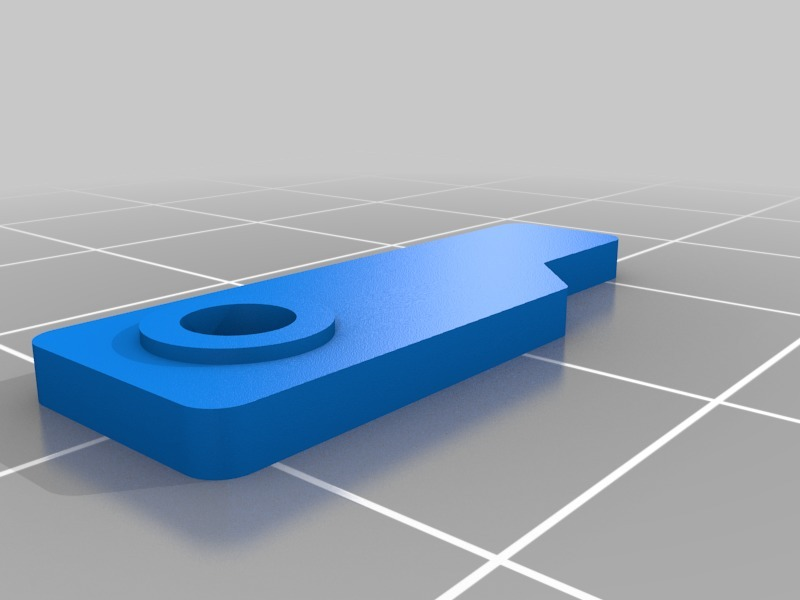

I have a decent cable management system in place now. I'm using https://www.thingiverse.com/thing:11978 for a cable chain on the Y-axis and using just a cable loom. I uploaded a new Y endcap and two loops for the cable loom. the Y endcap needs 3 brass inserts. Pictures will be uploaded later today.

Update 2/25/2018

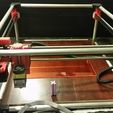

I added an enclosure, but I'm still working on cutting the press board that I'm using for the "laser proof window" with an OD 3. I created 4 L/U channels that I solvent welded to the corner pieces. This allows me to just slide in the sides and remove them at any time, in case I need to cut or engrave something bigger. The top will just sit on top of the corner pieces and be held in place by the sides that I cut a little longer.

I also really need to start working on cable management. The cable loom was dragging and cut by the laser. I caught it in time before the cables were cut. In the printer configuration I generally have enough "wasted space" in the back for the drag chain to bend. However, without a Z-axis you can use the entire Y travel, so I need to figure something else out. Without a case the choice would be easy. My current thought is to have a cable chain for Y and then a spiral wrap for the X with a loop/holder on the X-carriage and the left Y-carriage. If you have any ideas please post it in the comments. Thanks!

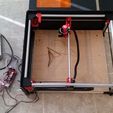

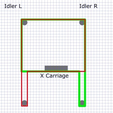

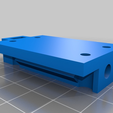

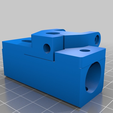

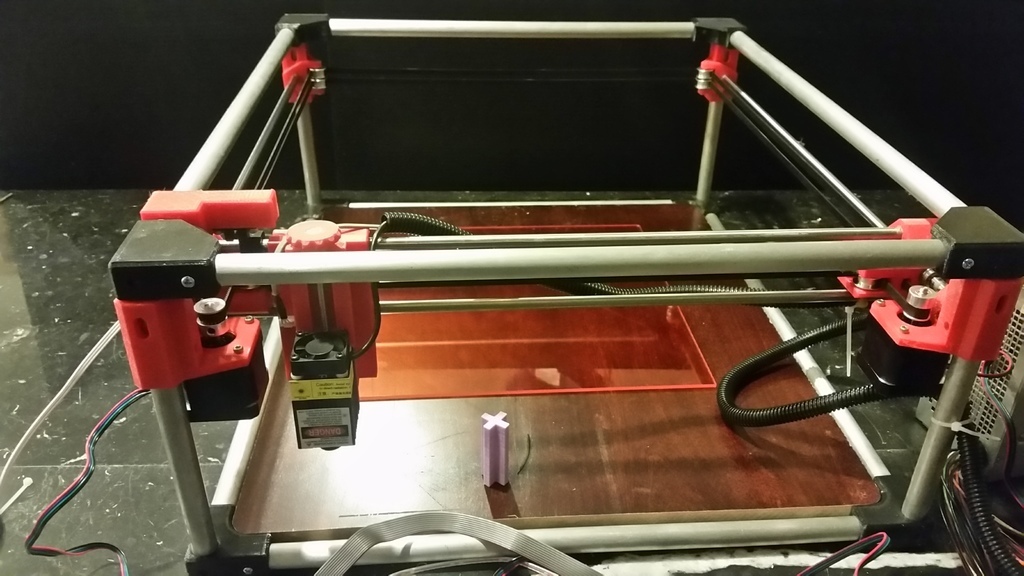

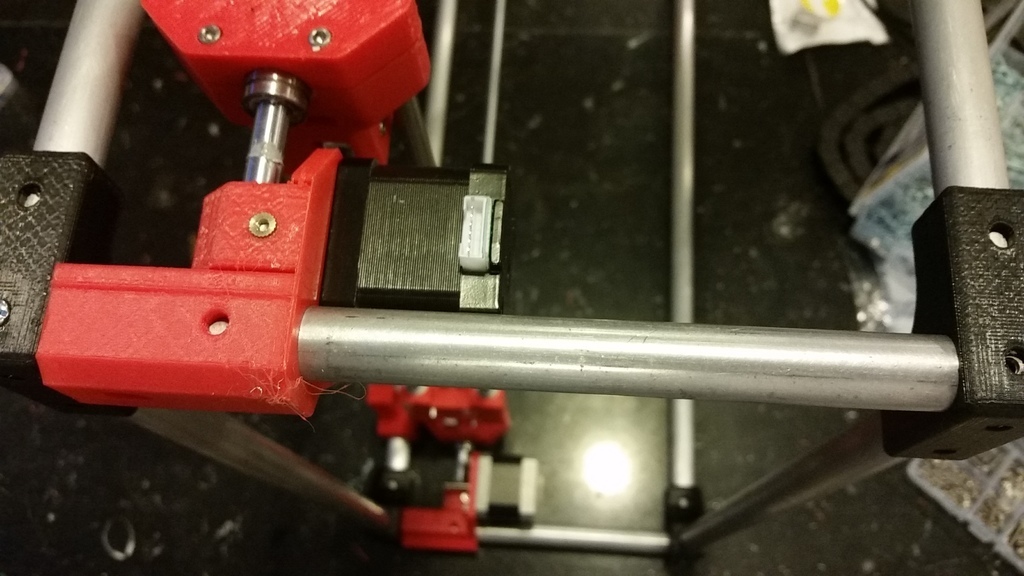

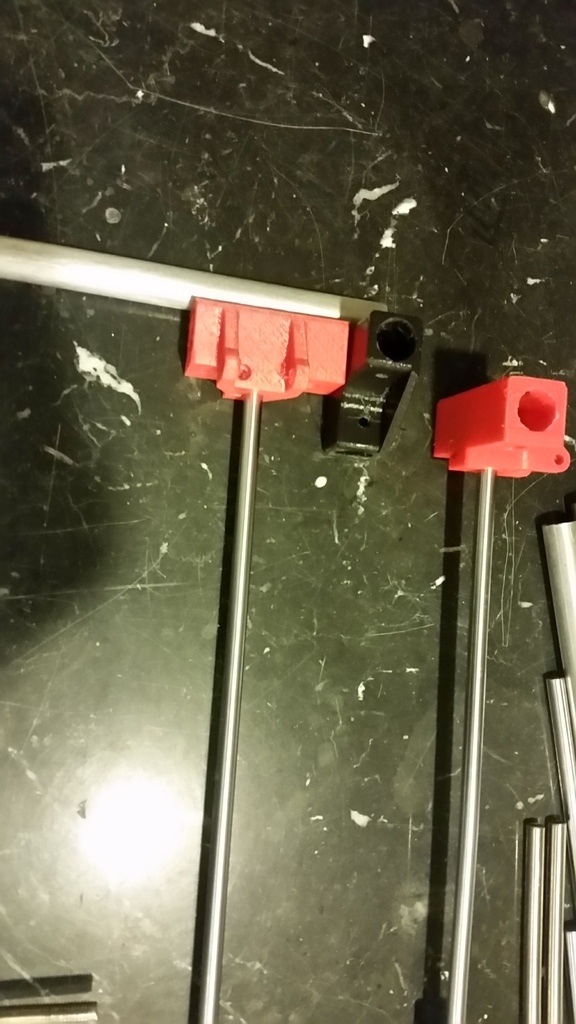

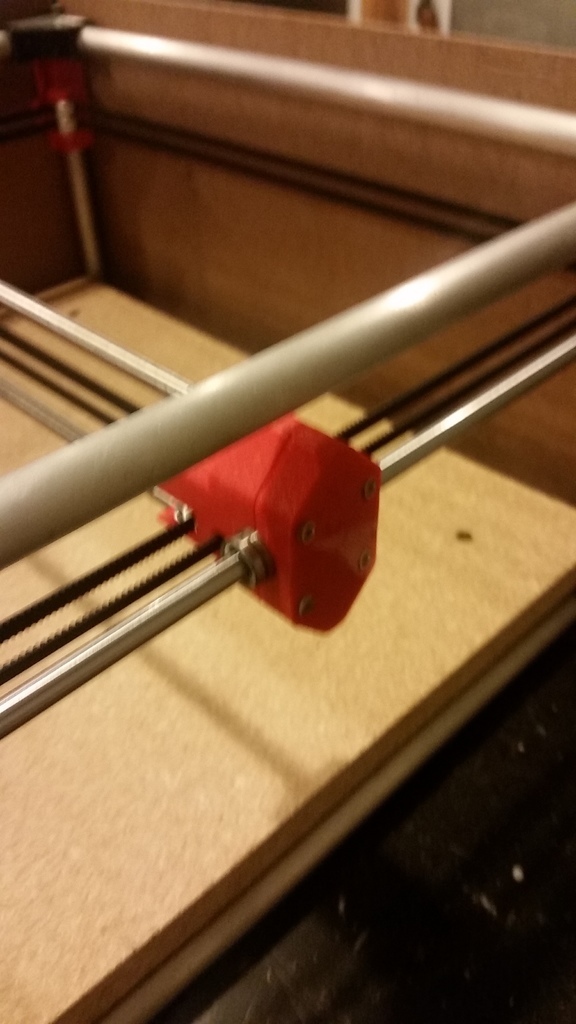

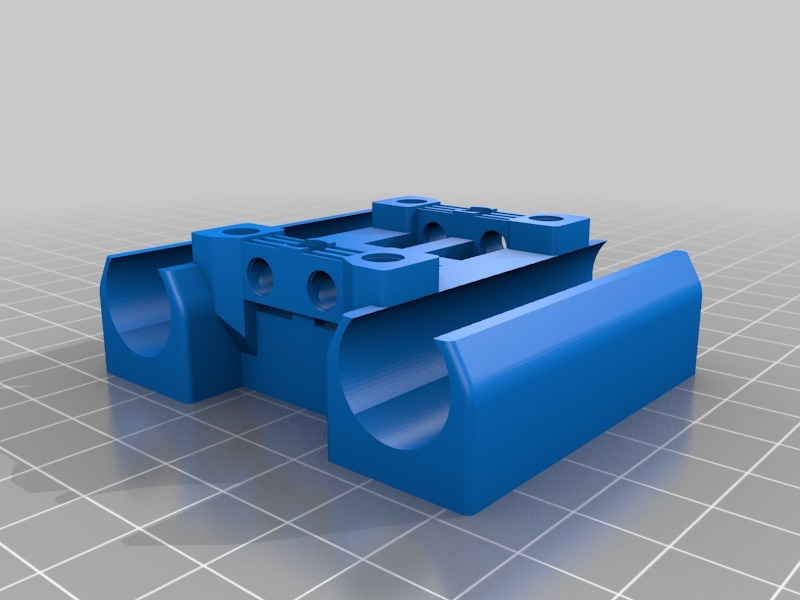

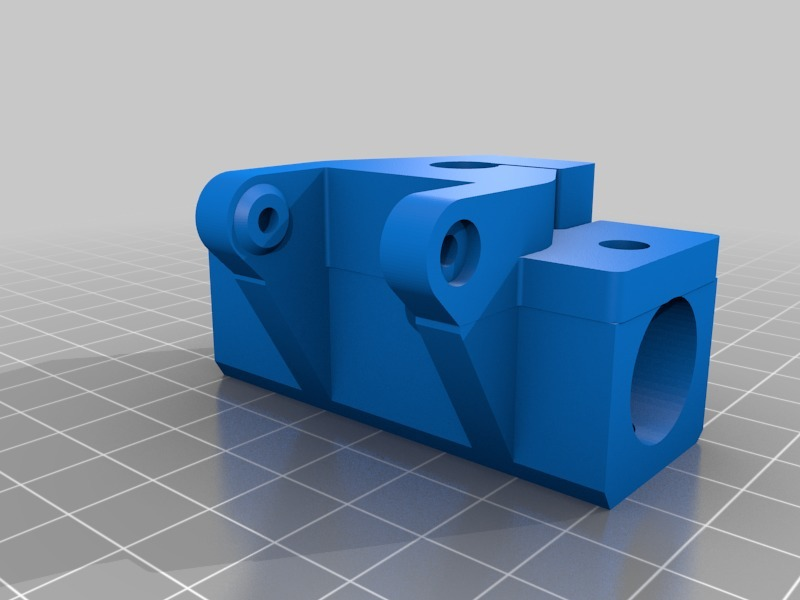

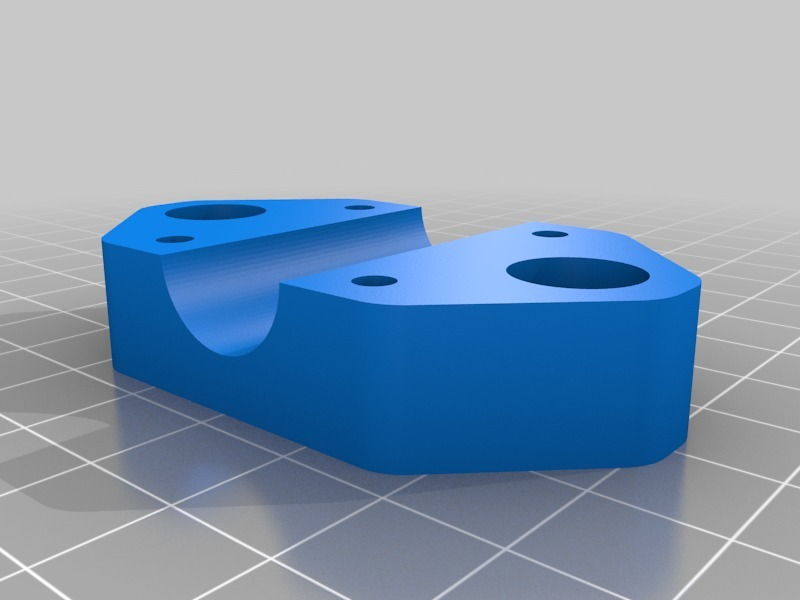

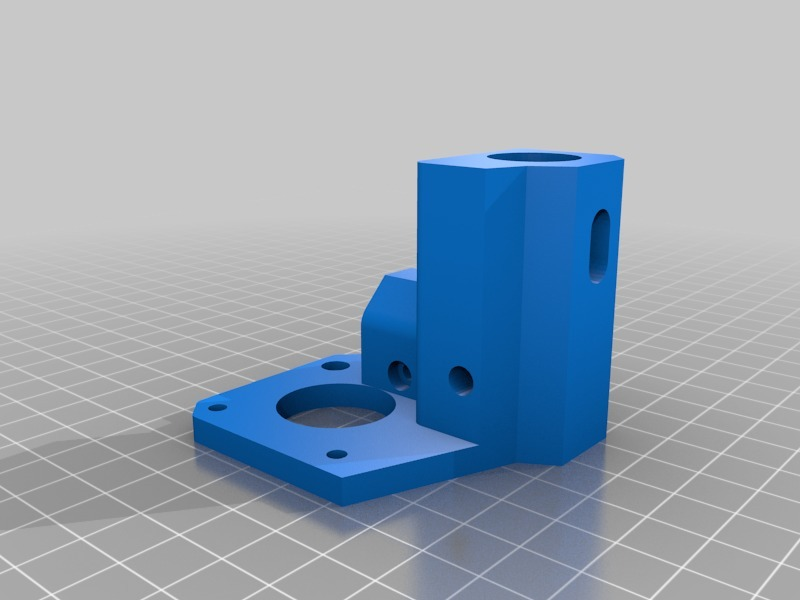

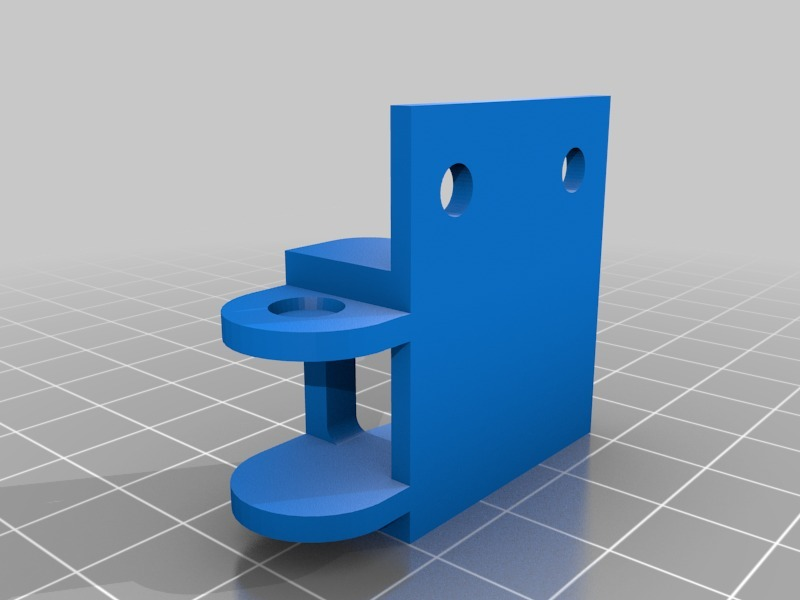

This is a 5/8" or 16mm Tube CORE-XY frame concept. Some parts are based on Scott_3d's excellent Hypercube Evolution.

The project started with a impulse purchase of a 2.5W laser. I then went through my leftover bin and found that I had many key components to build the 3dp burner/engraver. Long story short I printed the parts and then decided I really wanted to stick with the core-xy concept. I had some 5/8" aluminum tubes laying around and decided to use them as a frame vs. the expensive extrusions.

So here is my rendition of a Tube Cube HEVO Engraver. Wait! Is this not then a 3d printer? I guess you could make it into one by adding a z-axis.....

BOM:

- 5/8" or 16mm tubing aluminum ( probably could use steel too)

Y-axis 500 mm = 400mm print area

X-axis 440 mm = 300mm print area

Z-axis 220 mm

- 4 x 8mm linear rails

Y-axis 500 mm

X-axis 460 mm

- 8 x 8mm linear bearings

- 1 x RAMPS 1.4

- 1 x Arduino Mega

- 2 x Stepper drivers

- 2 x Stepper motors

- 1 x Power supply

- 100 x brass 3mm inserts

- bunch of screws (some sheet metal, nuts and bolts, etc.)

- number 10 x 3" screw with 4 nuts for the z adjustment

- 6 x tooth pulleys T20

- 2 x smooth pulleys T20

- Some PLA

BONUS:

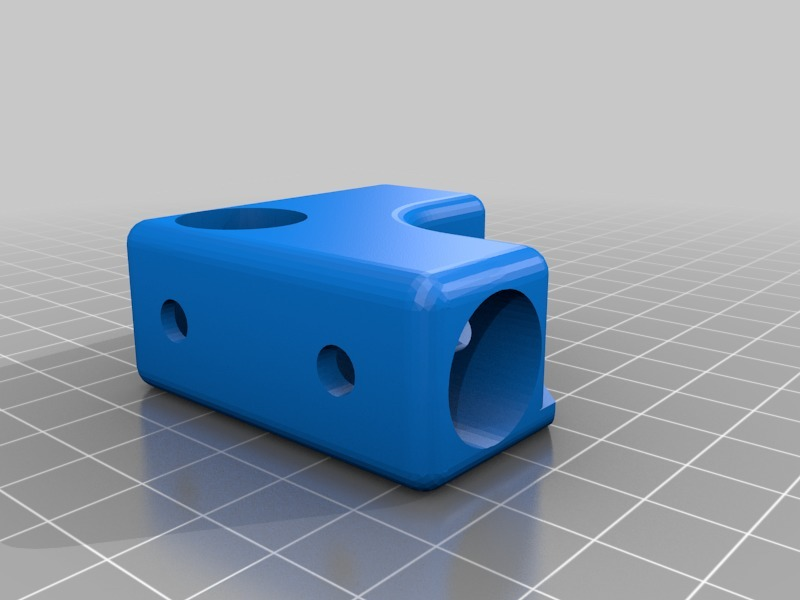

- Added my other corner piece that will allow you pass the vertical tubes through it. will come in in handy if you want to build a dual z-axis tube cube. It was not needed for the engraver version. (Lightweight_midpiece)

/https://fbi.cults3d.com/uploaders/28376834/illustration-file/75eae30c-3e25-46ce-b345-3c4bd223bdfc/20180220_191736.jpg)