You can find this here: https://www.myminifactory.com/object/3d-print-99536

UPDATE 3/2/2018

I tried the Klipper firmware on the MINI and it looks promising. Lots of fun watching this thing crank away at 100mm/sec. Currently it's like a sports car that is meant to go fast, but has no comforts. I hope the auto bed leveling will be industrialized soon as that is the only thing I really miss. It has it somewhat enabled, but the intent seems to be to run the bed leveling and then use the values to update the config vs. it just running automatically before the print job. It also doesn't have the LCD working, but I can upgrade my RPi to a 3.5" LCD and that would handle my last requirement. I'll post the config file near the bottom of this summary just in case someone wants to try it...

UPDATE 2/14/2018

I was able to sell my old CTC frame and other parts I didn't use for $20, so the cost is now down to $324 for the build!

UPDATE 2/10/2018

Just to note that this is a remix of the fabulous Hypercube Evolution by Scott_3d. This means that you can use the configuration XLS that is available @ https://www.thingiverse.com/thing:2254103 to change the dimensions. However, you will be increasing the cost of this upgrade and may just consider buying it all and going to a 24V setup. Mini HEVO cost:

- Extrusions: ~$80

- 10 x 3030 inside corners: $11

- J-hotend $5

- Screws ~$20

- Optical endstops $3

- Teflon tube $2

- Nylon Cable chain $8

- 2x 12mm linear rails: $20

- 4x Linear 12mm bearings $6

- 100 x 3030 Hammer nuts: ~$12

- 50 x 2020 Hammer nuts: ~$6

- Belt & pullys: $18

- Galvanized Sheet Metal: $5

- Glass: $3

- Loom: $5 .

- CTC printer: $140

Total: $344

A full build would be at least $500.

UPDATE 2/8/2018

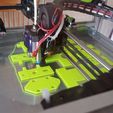

I added some aluminum tape to the bottom (formerly the top) of the heatbed. It heats up to 65C in about 3 min. HERE is the kind of tape I used

UPDATE 2/3/2018

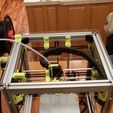

Added two 2020 brackets and two 2020 braces to the build. there just seems to be too much flex with the 2020 extrusions I bought, but of course they were super cheap! The ones I bought from 8020.net seem stronger, but I had to grind down all the hammer nuts to make them fit. I'll gladly print a couple of extra brackets to not do that again ;).

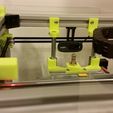

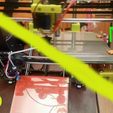

This is a "Extreme Makeover 3D Printer Eddition". I bought my CTC Prusa I3 off craigslist in November 2017. This is the first printer that I purchased and my only intention was to print parts for a Hypercube Evolution. So now that the Hypercube Evolution is done, calibrated and has way better prints than the CTC Prusa, I figured I'd upgrade it so I can have it as a backup. At first I was only looking at doing a AM Prusa build, but then i thought better...ANOTHER HEVO.

The goal of the project is to use as many parts from the CTC as possible and print as many parts as possible:

CTC Parts re-use:

- GEETECH Board

- Power Supply

- Heatbed

- Steppers

- Rails

- Linear Bearings

- Screws

- Cables

Upgrades:

- Board bootloader and Marlin 1.1.8 (note I have detailed instructions on the upgrade HERE).

- Upgrade to optical endstops

- Upgrade the Min Endstop connectors on the board to 3 pin (+5V, Signal, Ground)

- Upgrade to Auto-leveling with proximity sensor

- J-Head style hotend

- Bowden drive

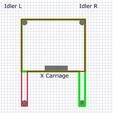

Build volume: 200mm x 200mm x 180mm

BOM:

- 3 x optical endstops

- 2 x 12mm linear rails (400mm) need to cut it down

- 8 x 350mm 3030 extrusions (standard size you can buy already cut, but you could go shorter)

- 4 x 400mm 3030 extrusions (standard size you can buy already cut, but you could go shorter)

- 2 x 340mm 2020 extrusions (buy what you can and cut down. DON'T buy 2020 from 8020.net. You can't use hammer nuts on their 2020 extrusions)

- 2 x 140mm 2020 extrusions (buy what you can and cut down. DON'T buy 2020 from 8020.net. You can't use hammer nuts on their 2020 extrusions)

- 100 x M5 Buttonhead screws 10mm

- 100 x 3030 hammer nuts

- 50 x 2020 hammer nuts

- Teflon grill mat (smooth, not rippled)

- Galvanized metal sheet 26ga or 28ga

- Glass for the the heatbed with corners trimmed (from Hardware store)

- 3mm screws HEVO screw kit (cheaper than buying them individually)

- J-hotend $7

- Extruder or print one and purchase the connectors which saves about $4

- Nylon cable chain. I've printed several, the nylon just holds up better IMHO and is only $8

- 3mm Nut inserts (5mm x 5mm)

- Fiberglass reinforced T20 belt

- 6 x toothed idler pullies

- 2 x smooth idler pullies

Print list:

- see files. Piece count is in the file name.

- Many parts are directly from HEVO

- Some have been modified e.g. extra long X end stop flag, Z top mount to provide clearance for drag chain, etc.

- I used green PLA from ZYLtech. Printed nice, but go easy on the soldering iron temp when inserting the brass inserts.

Board mod:

- Remove min connector housings from board

- desolder/remove the connector housing from the optical enstops

- Use one pin from the removed optical endstop and solder to the Arduino board +5v

- Place optical endstop connector over the 3 pins

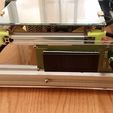

HOT BED:

- We will be mounting the hotbed inverted (heat element up)

- Desolder the leads and remove all the solder you can

- Solder the leads through the holes and make sure you keep the solder flush on the heat element side.

- Place a smooth Teflon Grill mat on the heatbed and cut to size This will make sure we don't short anything out

- Cut a flat 26 or 28ga galvanized steel sheet to size of the heatbed, drill holes for the bed leveling screws.

- Make sure the bed leveling screw heads are not higher than the glass you will be using. If you are using the CTC screws grind them down a little. you want the heads below the glass surface to protect your nozzle.

- Screw everything together and clip on the glass with the trimmed corners.

Extras:

Enclosure:

- Buy enough plexi glass to enclose the sides and top and bottom. I needed:

-4 x 16.125" x 16" (0.125" thick)

-2 x 16.125" x 16.125" (0.125" thick)

-4 x 3" x 15.875" (0.250" thick for the top brim)

- Plastic Solvent Cement (fuses plexi glass... needed for the top)

Octopi:

- Octopi with Logitech 270 webcam

- Print the webcam holder

- watch YouTube video on how to adjust focus

Klipper printer.cfg file

This file contains common pin mappings for CTC Prusa i3 printer board in

COREXY configuration. To use this config, the firmware should be compiled for

the AVR atmega1280.

Note that the "make flash" command does not work with CTC boards -

the boards are typically flashed with this command:

avrdude -p atmega1280 -c arduino -b 57600 -P /dev/ttyUSB0 -U out/klipper.elf.hex

See the example.cfg file for a description of available parameters.

[stepper_x]

step_pin: ar25

dir_pin: !ar23

enable_pin: !ar27

step_distance: .0125

endstop_pin: ^ar22

position_endstop: 0

position_max: 200

position_min: 0

homing_speed: 50

[stepper_y]

step_pin: ar31

dir_pin: !ar33

enable_pin: !ar29

step_distance: .0125

endstop_pin: ^ar26

position_endstop: 0

position_min: 0

position_max: 200

homing_speed: 50

[stepper_z]

step_pin: ar37

dir_pin: !ar39

enable_pin: !ar35

step_distance: .0025

endstop_pin: probe:z_virtual_endstop

#the

higher the number the closer it gets to the bed.

position_endstop: 0.15

position_max: 180

homing_speed: 20

[extruder]

step_pin: ar43

dir_pin: !ar45

enable_pin: !ar41

step_distance: .0102

#step

distance started with .0105

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: ar2

sensor_type: EPCOS 100K B57560G104F

sensor_pin: analog8

control: pid

pid_Kp: 21.27

pid_Ki: 1.74

pid_Kd: 64.91

min_temp: 0

max_temp: 250

[heater_bed]

heater_pin: ar4

sensor_type: EPCOS 100K B57560G104F

sensor_pin: analog10

control: pid

pid_Kp: 175.55

pid_Ki: 16.11

pid_Kd: 478.17

min_temp: 0

max_temp: 130

[fan]

pin: ar7

[mcu]

pin_map: arduino

serial: /dev/ttyUSB0

[printer]

kinematics: corexy

max_velocity: 300

max_accel: 3000

max_z_velocity: 25

max_z_accel: 30

[probe]

pin: ^!ar30

speed: 5.0

z_position: 0.0

The Z position to command the head to move to during a PROBE

command. The default is 0.

#activate_gcode:

A list of G-Code commands (one per line) to execute prior to each

probe attempt. This may be useful if the probe needs to be

activated in some way. The default is to not run any special

G-Code commands on activation.

#deactivate_gcode:

A list of G-Code commands (one per line) to execute after each

probe attempt completes. The default is to not run any special

G-Code commands on deactivation.

[bed_tilt]

x_adjust: 0

y_adjust: 0

points:

100,100

10,10

10,100

10,180

100,10

100,180

180,10

180,100

180,180

speed: 50

horizontal_move_z: 5

probe_z_offset: 0.15

/https://fbi.cults3d.com/uploaders/28376834/illustration-file/f3f6c71d-25b8-412b-ae60-964fb0180774/CTC_HEVO_upgrade.jpg)