3D model description

The 12 rounds .177 BRK Ghost, Daystate DeltaWolf and AlphaWolf Pellet Care Magazine.

Link to an instruction video, how to finishing the magazine after printing: https://youtu.be/wunxeoAX39A

Link to how to make the Tension spring use ø6 rod or pipe:

https://youtu.be/AMW_z_x5rE0

Further information about spring and assembly here:

https://1drv.ms/b/s!AmpEb51MwLqTh_cxLXGupN7SXw9Ycg?e=i4dbLF

Shopping list:

1 nos. M3x8 Flat counter sinked hex. socket screws (Black steel or electro galanized. Must be magnetic.

4 nos. Neodymium ø5x1.5 magnet

1 no. ø1 x 31 Steel (or Carbon) pin for hinges.

1 no. ø1 x 15 Steel (or Carbon) pin for pellet stop reinforcement

1 no. ø1.0 Steel or carbon pin for hinges.

1 no. Optional O-ring for holding pellets in place;

Inside Diameter: mm (Checking dimensions - coming soon)

Outside Diameter: mm (Checking dimensions - coming soon)

Thickness: 1.5mm

1 no. Spring loaded ball plunger type: YXP03 3mm x 4

https://www.aliexpress.com/item/1005002175468912.html

Important notice: All my files are designed at numeric dimensions. Example in this magazine the hole in the rotor is made 7.00 mm and the shaft is also designed as 7.00 mm.

This means that your printer must be calibrated in X,Y,Z and Estep for the extruder.

Alle tolleranceses so that the 7.00 mm center hole in the rotor fits over the ø7.00 shaft gets measures so the rotor rotates freely in the body, without too much play.

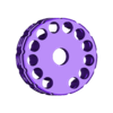

The rotors cavities for the slugs is carefully smothened with a 4.5 to 5mm round file. Print the rotor with the numbers towards the print bed.

I prefer quality over speed so i print at 50 mm/s.

When I print with ABS scale the parts in X and Y 100.4% not in Z.

Important - do not test the rotor in the body before the pelletstop pin has been reinforced. The pellet stop is fragile without reinforcement and can easily snap of.

Use one ø1 x 15 mm steel or carbon pin. (Glue the pin in place with a thin CA glue) Cut to precise length after the glue has cured

Cut m3 threads in the center hole for the m3x8 countersink steel screw.

Use four ø5 x 1.5 neodym. magnet for the cover and the body.

Use a 1.0 x 31 mm steel or carbon rod for the hinges.

Drill free with a 1 mm drill first while the cover is fixed in place.

Use a ø4.8 mm reamer or a 4.8 mm drill to ensure that all pellet holes in the rotor are perfect dimension, round and smooth.

Drill the center hole in the rotor up with a ø7.0 mm dribit

3D printing settings

3D PRINTING SETTINGS

I use ABS printed on a glass bed with DimaFix spray at 100 degrees C.

I also sometime use Petg for the body, washer, and cover, but very seldom for the rotor. The rotor is coming out of the printer with superior quality – specially numbers are easier to print with ABS. Also removing the support for the O-ring will be easier without damaging the rotor.

I print all with 0.16mm layer height. Be sure to calibrate your printer at optimize your slicer. Everything is designed to 0 tolerance so use your slicer XY horizontal compensation.

Infill 30%

Supports when printing.

Body: yes full supports - Prints with the exit pellet hole down towards the printbed.

Cover: no supports - Prints with the text down towards the printbed

Washer: no support - Prints with the large diameter down towards the printbed

Rotor:

Standard rotor - supports not needed. - Prints with the flat surface down towards the printbed

Rotor with o-ring groove - use full support. - Prints with the flat surface down towards the printbed

I recommend using the .3mf files over the .stl files - The .3mf files will give smoother roundness.

/https://fbi.cults3d.com/uploaders/25717936/illustration-file/f1ce65f5-87cb-4121-a277-26e9e7b554ee/BRK-Ghost-Daystate-DeltaWolf-.177-8.jpeg)