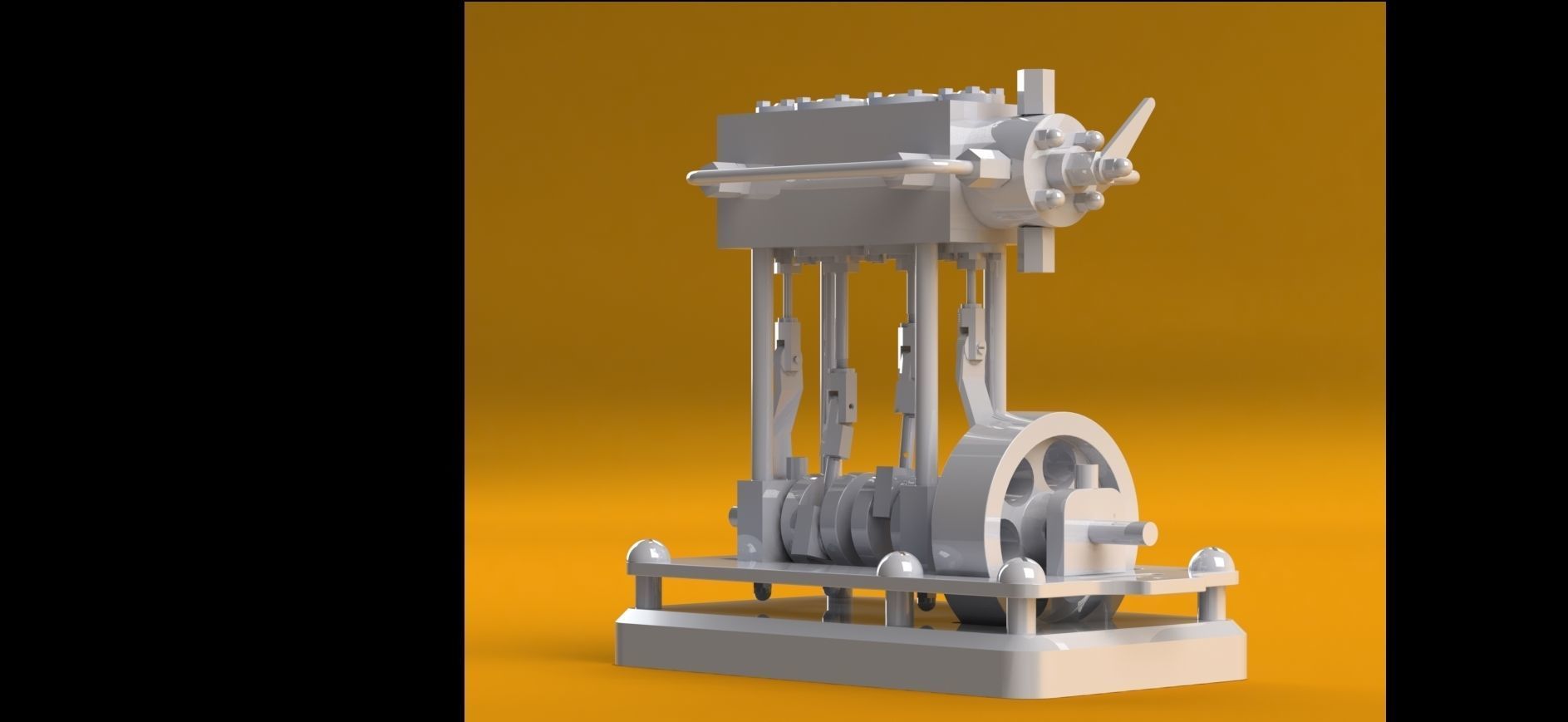

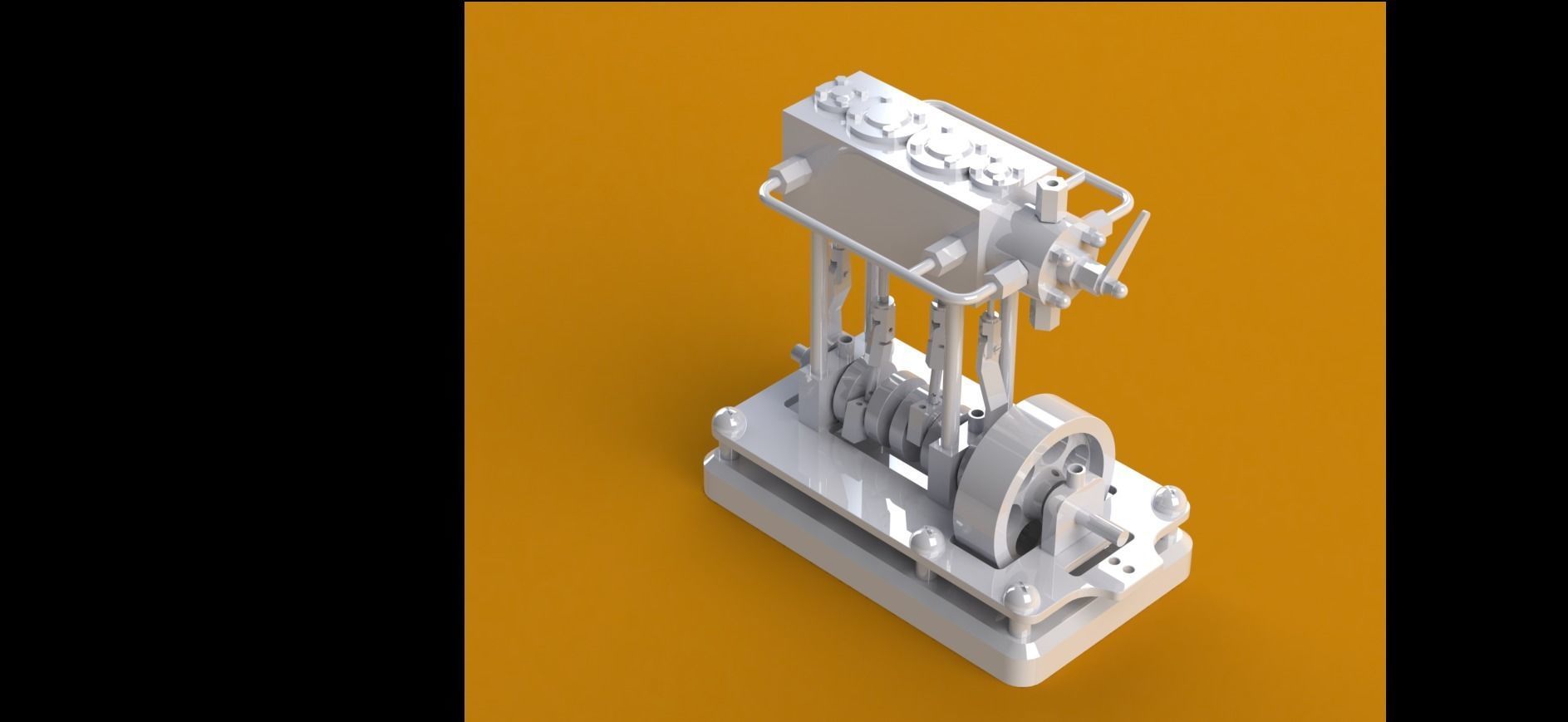

solidworks 2 cylinder vertical marine type steam engine assembly 3D model

this is a sample model of 2 CYLINDER VERTICAL MARINE TYPE STEAM ENGINE (BORE 24 X STROKE 28) in solidworks part modelling and assemble . there so many parts of this machine which i made in solidworks and assemble it also

A 2-cylinder vertical marine type steam engine is a specific configuration of a steam engine commonly used in marine applications, such as ships and boats. This type of engine consists of two vertically arranged cylinders that work in tandem to convert steam pressure into mechanical motion. It's a compact and efficient design suitable for powering marine vessels during the era when steam power was widely used for propulsion.

Components:

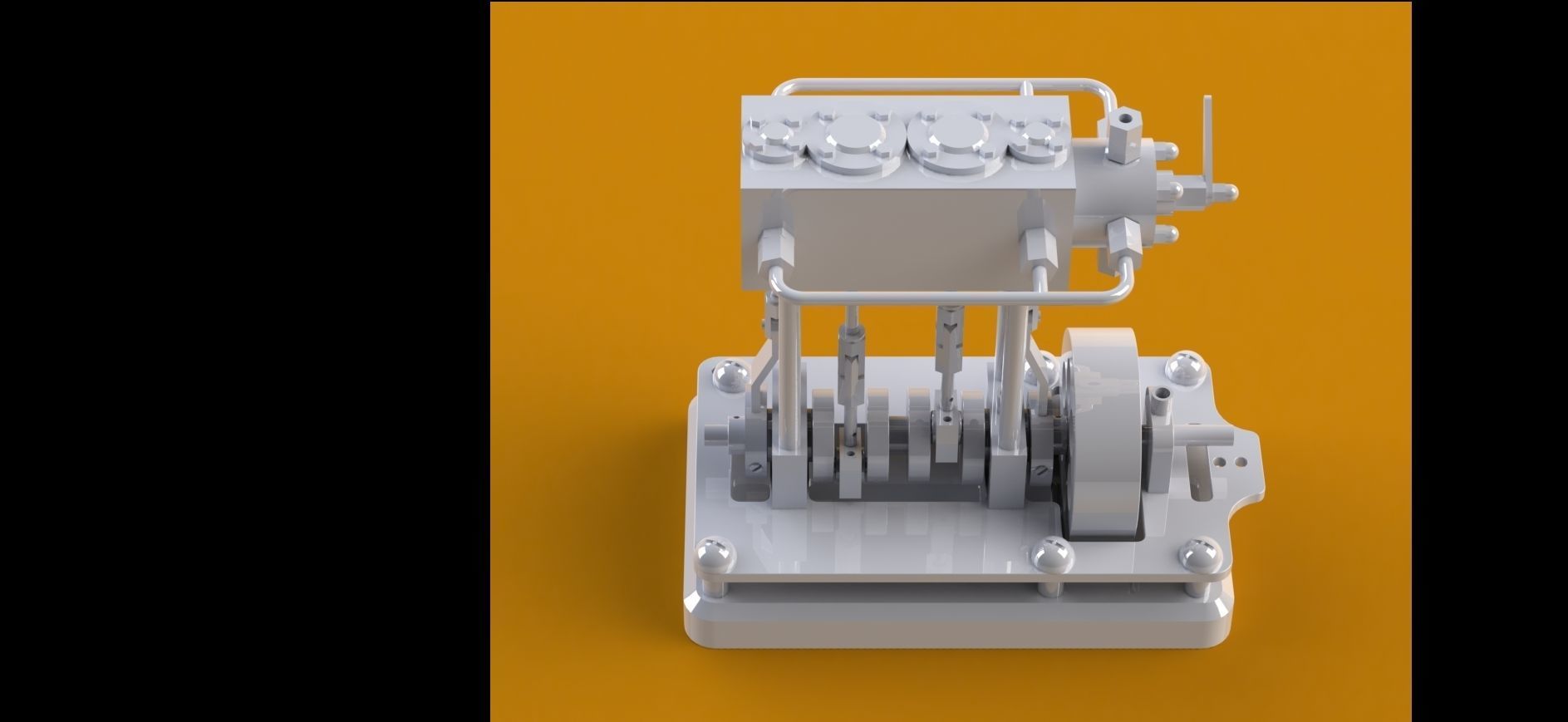

Cylinders: The engine has two vertical cylinders placed side by side or in-line. Each cylinder contains a piston that moves up and down within it.

Pistons: The pistons are cylindrical objects that fit snugly inside the cylinders. They move up and down in response to steam pressure, creating reciprocating motion.

Crankshaft: The pistons are connected to a common crankshaft. The rotational motion of the crankshaft is generated from the reciprocating motion of the pistons.

Connecting Rods: Connecting rods connect the pistons to the crankshaft. They transfer the vertical motion of the pistons into the rotational motion of the crankshaft.

Valve Mechanism: A valve mechanism controls the flow of steam into and out of the cylinders. This mechanism determines the timing of steam admission, expansion, and exhaust.

Flywheel: A large, heavy wheel is connected to the crankshaft. The flywheel helps to smooth out the engine's rotation and store kinetic energy, ensuring a continuous and even output of power.

Working:

Steam Inlet: Steam is admitted into one end of the first cylinder through a valve. The steam pushes the piston upwards.

Power Stroke: As steam expands and does work on the piston, it moves the connecting rod, which in turn rotates the crankshaft. This is the power stroke.

Exhaust: After the power stroke, the valve mechanism opens to allow the used steam to exit the cylinder.

Piston Return: The momentum of the flywheel and the connecting rod mechanism bring the piston back to its original position.

Steam Switch: As the first cylinder completes its power stroke, steam is admitted into the second cylinder. While one cylinder is in the power stroke, the other is in the exhaust stroke.

Advantages:

Compact Design: Vertical arrangement of cylinders saves space, making it suitable for marine applications where space is limited. Balanced Operation: The twin-cylinder arrangement helps balance out the forces on the engine, reducing vibrations and providing smoother operation. Disadvantages:

Complex Valve Mechanism: The valve mechanism controlling steam flow requires precision and maintenance. Efficiency Challenges: Older designs might have lower efficiency compared to modern engines due to limitations in steam utilization. These engines played a crucial role in the history of maritime transportation, contributing to the Industrial Revolution's advancements and powering various types of vessels. While steam power has been largely replaced by more advanced technologies, the vertical marine type steam engine remains an important part of engineering heritage.