3D model description

This is my updated and final version of the Beta Radiation Absorbing Container designed to store radioactive samples like Uranium Minerals and Radium watch hand collectables. The updated design uses Bismuth as a shielding metal and molds made from high temp resin or high temperature nylon CF. Below are detailed instructions on printing the models and casting the bismuth to shape/

Printing the BRAC components:

The BRAC container, bottom cover and lid should all be printed with a high density material. Nylon Glass Fill and PLA have the highest densities of most of the common printing materials. From material testing, Glass filled Resin and Glass Filled SLS Nylon performed 15% better at shielding radiation than ABS. ( https://docs.google.com/presentation/d/1QO5gSxPPYLcWFuOFe1E7Mr5HbsOLN_O2IsLbgrOymVc/edit?usp=sharing )

All of the models should be printed with 100% infill or 99 wall loops to ensure that it is printed as densely as possible.

The model currently fits a material sample 50mm in diameter. Print out the ‘Sample core’ model to check if your sample fits. Scale the remaining components as needed to fit larger samples.

The molds were printed in Formlabs high temperature resin with a HDT of 238° C. The next closest material to use is CF Nylon 6 with a HDT of about 180° C. Since the Bismuth melts at a low temperature and cools rather quickly, these molds can be used a single time (or multiple depending on the wear). The central core model retains heat the longest and may warp the model beyond use, so consider ‘Bismuth Vertical Mold C’ a replaceable part.

Print the core components in full infill, while wasteful, all of the molds are less than 200 grams and ensure that they will not warp as easily during the casting process.

Molding the Bismuth Components:

This molding process consumes roughly 900 grams worth of raw Bismuth that can be bought in bulk on Amazon. I recommend purchasing enough for 2 or 3 casts to ensure you have extra should spillage or oxidation occur.

The bismuth melts on the stove at medium heat in a standard steel or iron pot. Do not use a non-stick pot as the coating will burn and give off toxic fumes during the melting process.

Before pouring the Bismuth, heat the molds with a blowtorch to decrease the temperature gradient between the two materials. This heating will remove water vapor from the mold ensuring the Bismuth does not bubble over or pop due to the pressure.

Make sure you are pouring the metal on a cookie sheet or other non-meltable material in case of spillage.

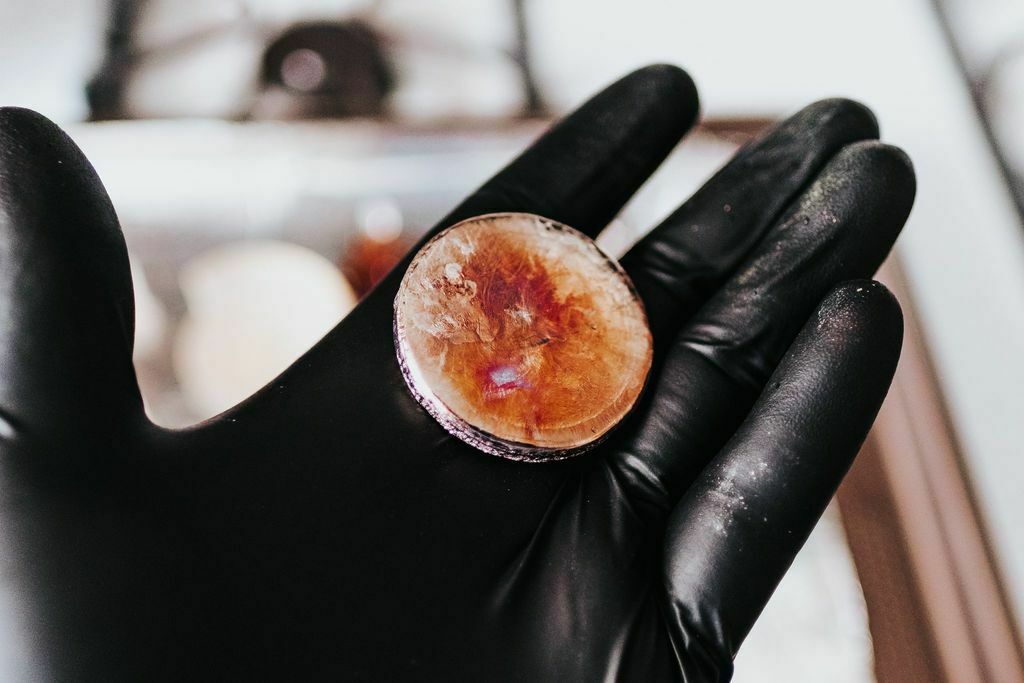

Wait until the castings are cool before handing. The Bismuth should have an oxidized top layer and raw shiny sides.

Bismuth is notoriously brittle so the molds can crack or break with little pressure applied. For the purpose of radiation shielding,. Mechanical strength is not required.

Assembly is simple, simply use double sided tape to secure ‘Small Mold” to the inside of the upper cap. The “Large Mold” is fixed in place on the underside of the container using the screw and key. The central core is slid into place and is held. While radiation can seep out of the cracks between the bottom, center and top castings, the gap is only 0.6mm between each section so the risk is minimal. Bismuth is a heavy element on the periodic scale and has exceptional beta radiation shielding properties due to its high amount of electrons in the nuclei. The Bismuth deflects and slows down electrons emitted during Beta decay or the Uranium mineral I’m using. This deflection as the electron interacts with the Bismuth nuclei creates Bremsstrahlung Radiation, which converts the kinetic energy into high frequency X-rays. These Xrays are then slowed by the Bismuth and shield the outside environment from the harmful radiation. While this works with gamma emitters like the Radium watch hands, the small amount of Bismuth does not do much. From my testing, the BRAC V2 is capable of reducing beta radiation by 95% and Gamma Radiation by ~50%. It has similar shielding effects to lead but does not produce harmful dust or debris. The Bismuth can also be recast for future versions of the BRAC or other projects.

My inbox is always open and I’m more than happy to respond to any questions. As it sits, this model is cheaper than buying an equivalent sized lead pig for the current material samples I am working with.

/https://fbi.cults3d.com/uploaders/14872565/illustration-file/b46c69ca-02ca-443c-b0ad-d89cf2e7a824/b058f01d-0ab4-4ff0-9262-b71aeaefd018.png)