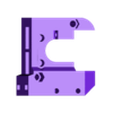

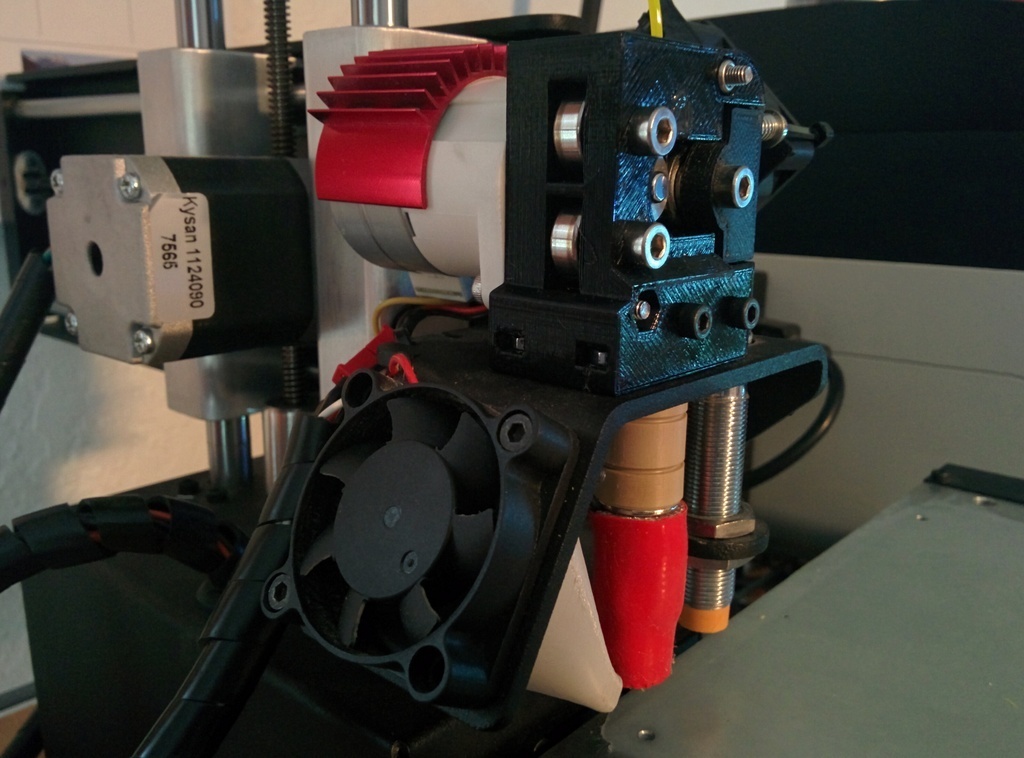

I ran into a lot of stepper skipping with Printrbot's aluminum direct drive extruder (stock on the Simple Metal), even with active cooling on the stepper motor and the current pots adjusted (up, down, middle, anywhere). My Ultibots K250VS kit introduced me to the world of skip-free extruding with their PG35L-based micro extruder, so I modified their design to fit the Simple Metal's bracket and ubis hot end. Later I realized that the uncooled ubis hot ends are total garbage (I can't speak for the cooled variety), so I swapped it for an E3D v6, which is all win all the time.

I've been printing with this extruder for years now with the ubis hotend and I haven't run into any issues with it.

Updated (9/8/2016): I successfully tested the E3Dv6 setup this morning. :) The fan shroud has been updated as it didn't fit as well as I would have liked. The spacers go between the delrin bocks that the 6mm rods fit into and the bed; longer M3 screws are necessary here (maybe 16mm, I'm not sure). If you have the bed insulator kit the delrin spacers that fit between the mount blocks and the bed are not necessary when using the 5mm spacers. You'll need 2 16mm screws (longer is okay, just be careful not to strip everything out) to secure the E3D v6 hotend.

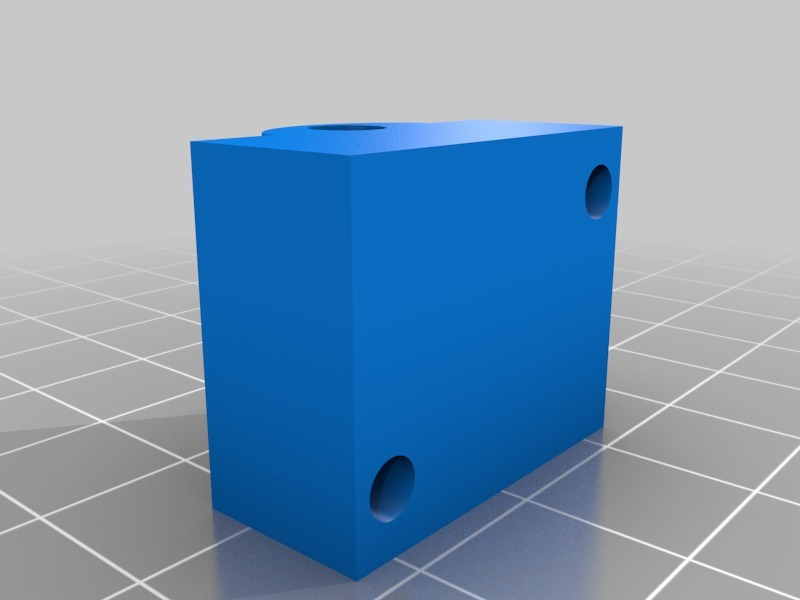

Updated (9/7/2016): Added a new extruder body to accommodate an E3D v6 hotend; an updated fan shroud and bed mount spacers have also been posted. The E3D hotend is significantly shorter than the standard printrbot ubis hotend; this requires raising the bed a bit so the Y movement assembly doesn't crash into the M3 socket head cap screws below it, a new fan shroud, adjusting the inductive bed sensor, and updating the firmware to use temp sensor 5 (semitec thermistor) in Marlin instead of 0. The E3D hotend does fit in the new extruder body, but I don't have it up and printing yet - maybe this weekend. :) The new fan shroud is reasonably well aligned, but not quite perfect yet.

Updated (3/6/2016): Added the idler STL from the MicroExtruder v5 thing for easy access and added a few more details to the summary.

Updated (3/2/2016): Added a new version with a revised hot end securing mechanism (rev2). The side-slot-based mechanism has been iffy since the beginning; the new part secures the Ubis hot end via two M3 x 16mm screws or one M3 x 20mm and one M3 x 16mm. The mounting screws have changed as well - 3 M3 x 10mm screws now. The fit has been tested as of today and it's a huge improvement over the side-slot mechanism - the hotend is rock solid now. I've removed the previous files. The latest .stl doesn't have the built-in supports as I use Simplify3D and these don't slice properly in S3D. I can add the built-in supports if anyone cares. Given the traffic to this model I doubt anyone does, but who knows. :)

Important: The PG35L may not require active cooling, but it's not a bad idea as it contains delrin gears that can fail at high temperatures. I've included my simple fan bracket for a 40mm fan. The heatsink is likely not needed if actively cooled, but it looks fancy.

See the original micro extruder design (and hardware BOM) here:

http://www.thingiverse.com/thing:42112

The hardware kit (3x 624zz ball bearings, M3 and M4 screws and nuts, springs, MK7 drive gear), PG35L motor, and heat sink can be purchased here:

http://www.ultibots.com/micro-extruder-v5-hardware-kit-3mm-drive-gear/

http://www.ultibots.com/pg35l-048-geared-stepper-motor/

http://www.ultibots.com/35mm-heat-sink-tall-fin/

This version of the micro extruder requires an additional 3 M3x10 screws and 3 M3 standard nuts to mount to the Printrbot Simple Metal Frame (others untested). I don't remember the lengths of the original extruder mount screws, but there may be some overlap there.

Sketchup 2015 source files are included.

/https://fbi.cults3d.com/uploaders/30568940/illustration-file/6891175a-62a4-4be9-b0f1-92085ddea38c/IMG_20160908_062506.jpg)