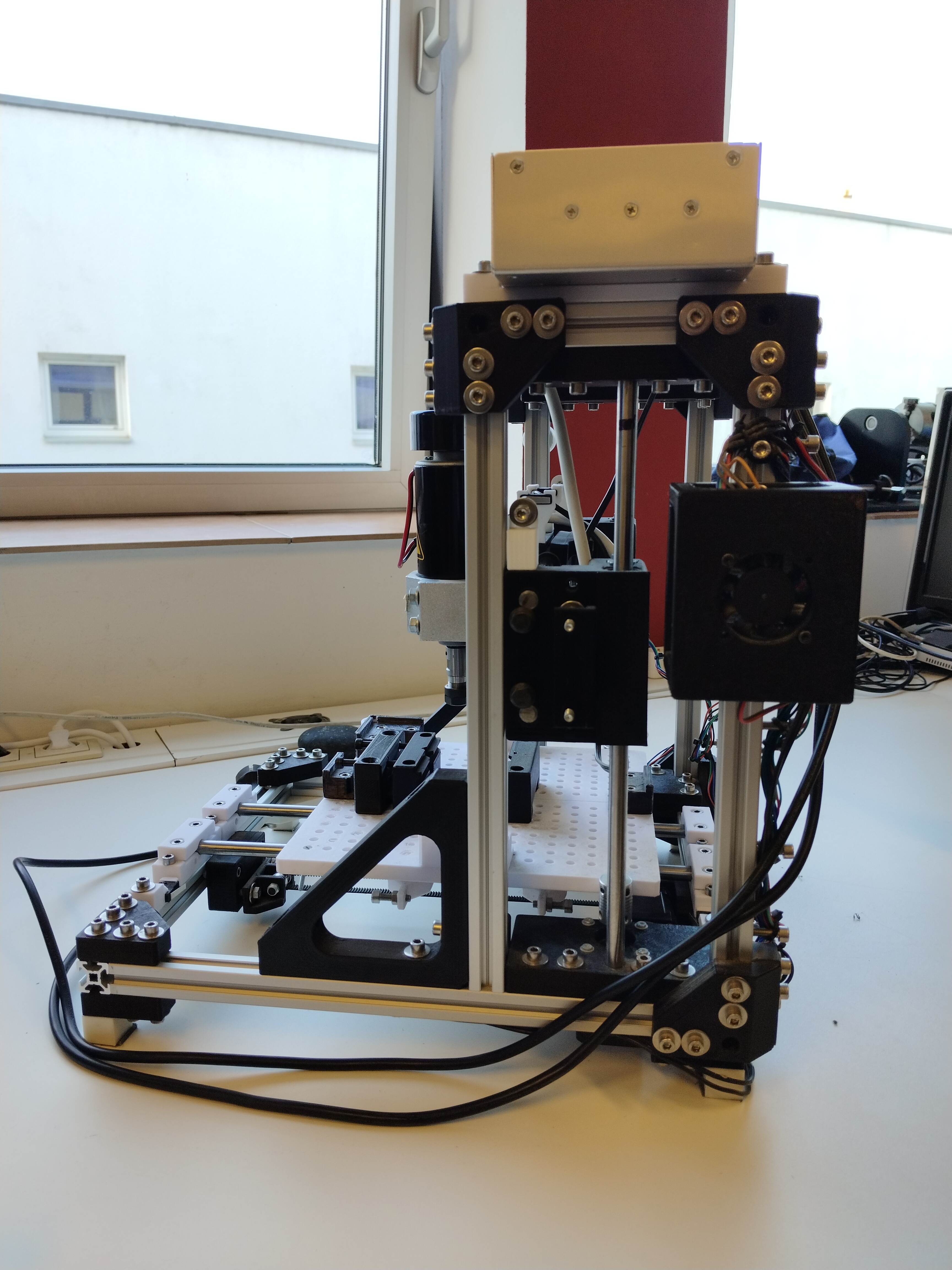

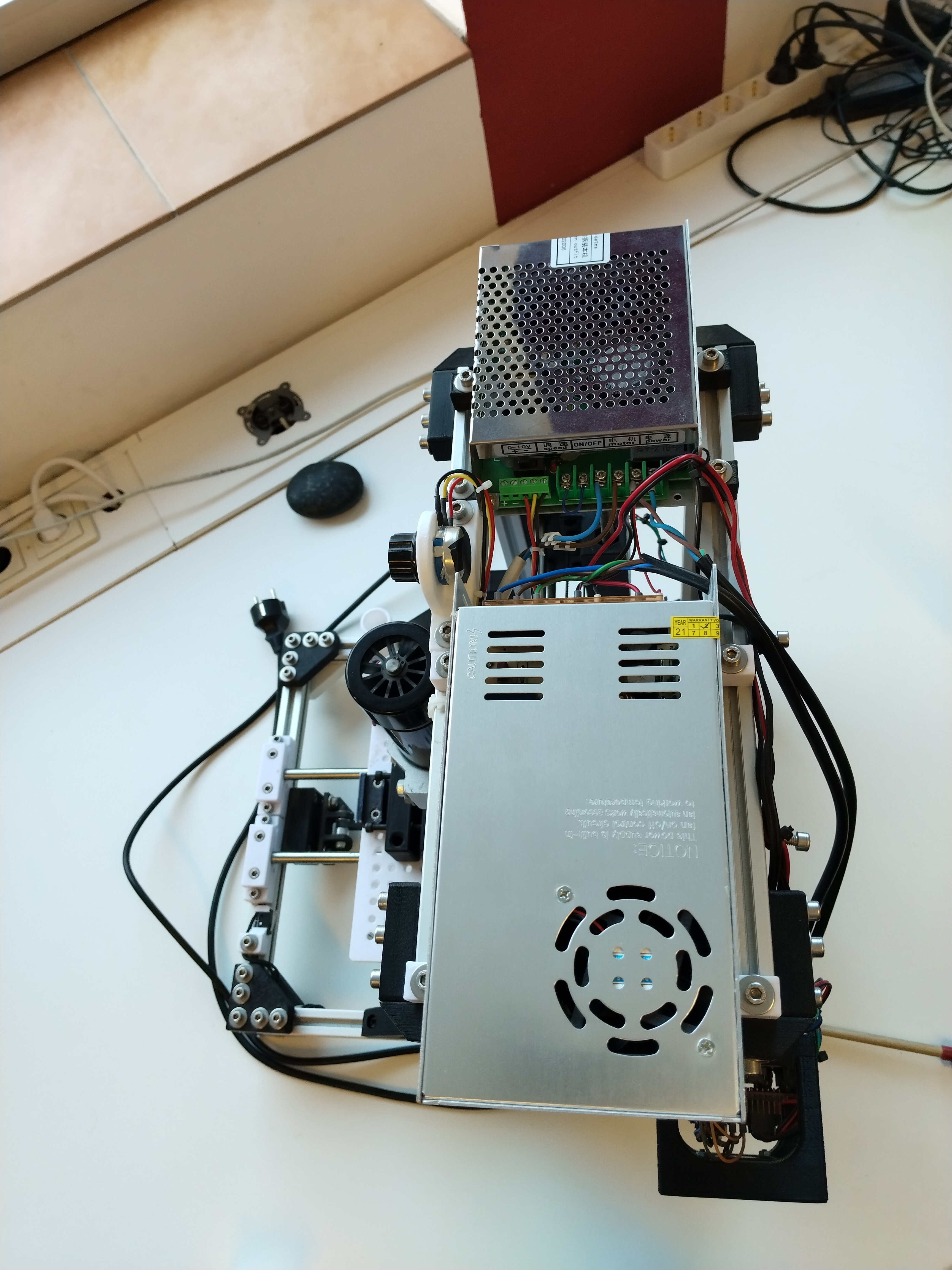

This CNC has the advantage over all others that it can process workpieces up to a height of 160 mm.

Most can only process lower heights

(depending on the cutter length).

This CNC is designed to process wood and plastic.

With careful working with a clamping depth of approx. 1.5 mm, aluminum is also possible, which can be seen in my video.

https://youtu.be/NZhTCcC9eJU

I recommend an Arduino with a CNC shield and Estlcam as the controller, but other controllers are also possible.

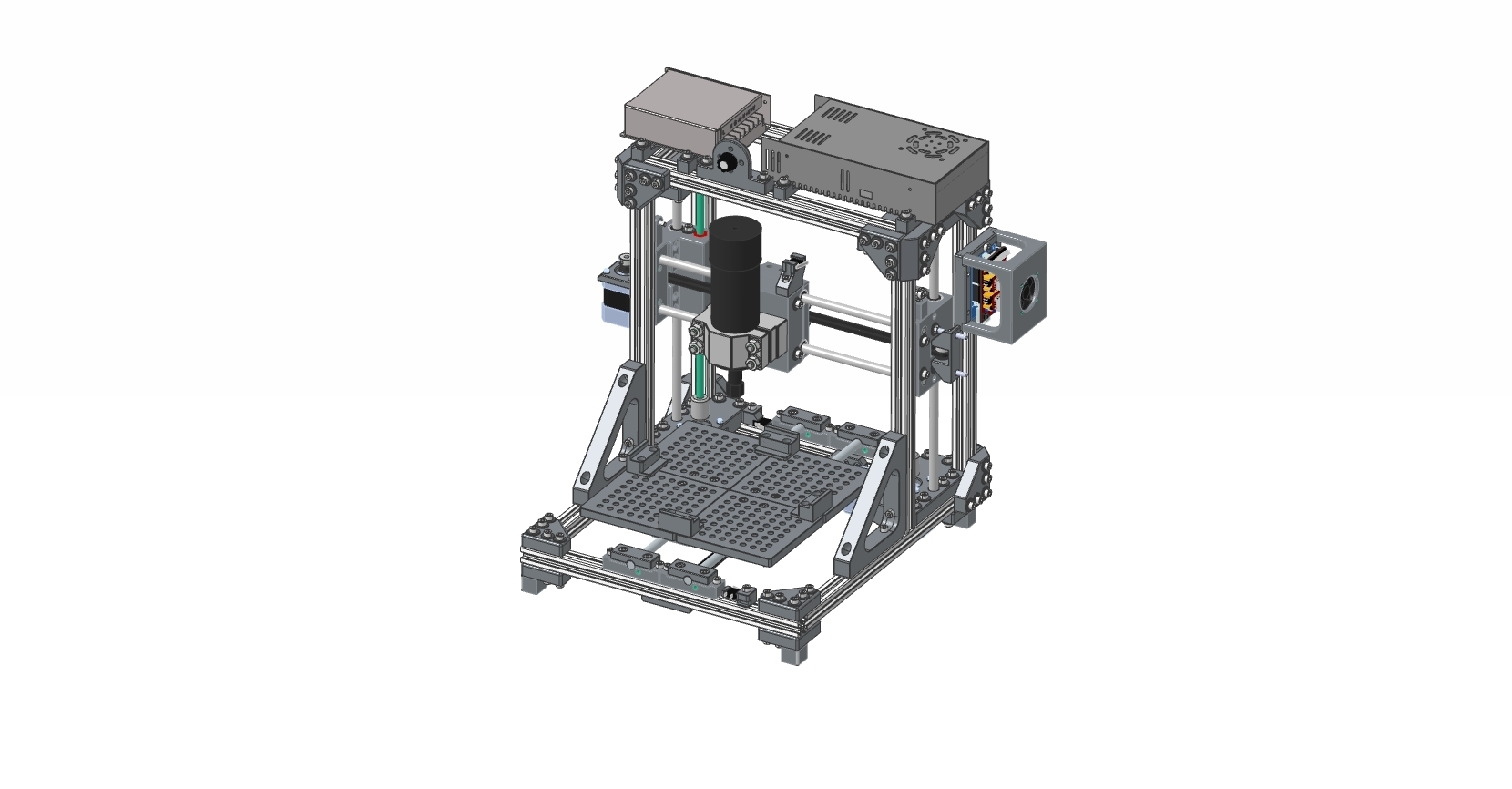

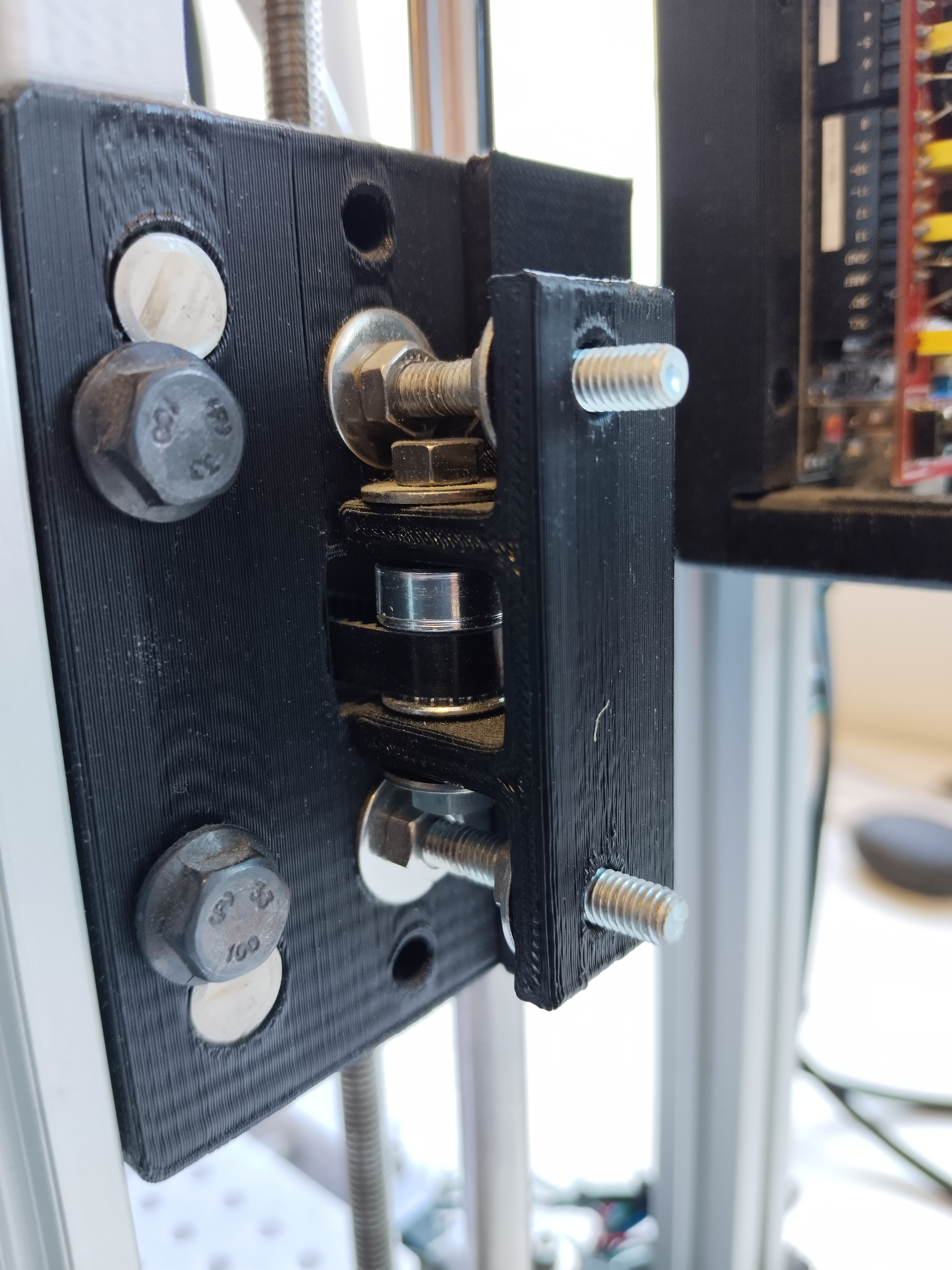

All but three parts are identical. These are designed so that they can be used several times, which makes printing and assembly easier.

The same M5 x 20 mm screws were also used wherever possible, making it easier for you to order the parts and assemble them.

As this CNC milling machine is not much bigger than a 3D printer, it also fits on your desk.

The external dimensions are X470 mm, Y400 mm and Z475 mm.

The machining is 210 mm for the Y-axis, 200 mm for the X-axis and 160 mm for the Z-axis, depending on the milling cutter used.

Here you can get free instructions, dimensions and information about this CNC.

If you are interested in buying, you can follow the link and get the whole package.

https://cults3d.com/en/3d-model/tool/e-cnc-drehrumbum

All parts are designed to be printable without support material.

For all buyers: You will soon receive the parts for a fourth axle, which is currently being tested, free of charge. You will also receive a vice specially designed for this router and a device for grinding knives. All these parts are still being tested extensively by me at the moment so that you will have a lot of fun with it and there will be no problems.

If you have any errors or problems, write to me, if possible with a picture, and we will solve them together.

This CNC has the advantage over all others in that it can process workpieces at a height of up to 160 mm.

All others can only edit lower heights

(depending on the cutter length).

This CNC is developed to process wood and plastic.

If you work carefully, aluminum can also have a clamping depth of approx. 1.5 mm as it is shown in my video below.

LINK

I recommend an Arduino with a CNC shield and Estlcam as a controller. Although other controls are also working.

All but three parts are identical.These are designed to be used multiple times, making printing and assembling easier.

The same M5 x 20 mm screws were also used, which makes it easier for you to order the parts and assemble them.

This CNC milling machine is not much bigger than a 3D printer and therefore fits on your desk.

The external dimensions are X470 mm,Y400 mm, Z475 mm.

The processing is Y-axis 210 mm, X-axis 200 mm and Z-axis 160 mm, depending on the milling cutter used.

Here you can get the instructions, dimensions and information about this CNC for free.

If you want to buy it you can follow the link and get the entire package.

https://cults3d.com/en/3d-model/tool/e-cnc-drehrumbum

All parts are designed to be printed without support material.

For all buyers: You will soon receive the parts for a fourth axis, which is currently being tested, and a vice specially designed for this milling machine, free of charge.

As well as a device for sharpening knives. All of these parts are currently being tested extensively by me, so that you have a lot of fun with them and there are no problems.

If you have any errors or problems, write to me, if possible with a picture and we will solve them together.