3D model description

TT GAUGE: Something for true scale model railway modelers!

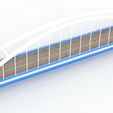

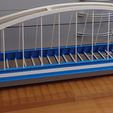

Precision scale model of modern railway bridge over river Rhône in Massongex, Switzerland.

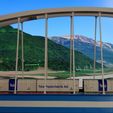

Original

- The original bridge is located on Lausanne-Brig railway line in Switzerland over the Rhône river near Massongex. It is the longest span bridge in the Switzerland. It replaced the older 2 bridges from 1903 and 1923 with 70m span. The older bridge was no longer able to support the heaviest D4 category trains, jeopardizing the railway operations.

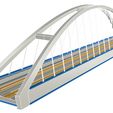

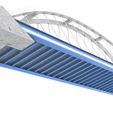

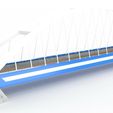

The primary metal structure consists of two metal arches inclined by 12° towards the inside of the structure and two longitudinal beams. The arches have a third central core in the axis of the hangers. Their height varies from 1.85m at the base to 1.20m at the top. The foot of the arch is embedded in the two supported transverse beams, with a height of 1.10m.

The longitudinal beams are also inclined in the same plane by 12°. They are made of I-shaped welded compounds with a constant height of 4m with a central core crossing the upper sole and to which the hangers are attached. In the area of the node at the end of the beam and at the intersection with the arch, the beams are box sectioned. The deformation of the bridge under eccentric railway loads is determining for the height of the beam. The longitudinal beams have a counter-deflection of 200mm, the transverse beams of 20mm. The longitudinal beams are connected to the arches by hangers (16 per side) made of flat iron with a section of 60mm × 300mm. The metal part of the deck is made up of 36 transverse beams spaced 3.40m apart, still in welded compound, with a height of 0.90m and with a counter-deflection of 20mm, which form a mixed section with the concrete slab.

- Key figures: Length: 125.80 meters, Width: 14.50 meters, Total height: 25 meters, Total weight: 8000 tons (2500 tons of steel, 3000 tons of concrete for the deck and 2500 tons of ballast/tracks).

- Construction: April 2015 to March 2017, Costs of the work: 34 million francs.

Source: https://www.espazium.ch/fr/actualites/un-nouveau-pont-ferroviaire-sur-le-rhone

Model Features

- Model bridge construction is similar to real bridge construction. All steel plates are re-created in the model and split to fit the printer bed size. Each big printed part (like arches and longitudinal I beams) need to be glued together with joins, the process is very easy. All parts for TT and N model size are displayed in the instructions, for H0, the big parts are split into more pieces to fit the printer bed size, but the process of joining them is exactly the same.

- Smooth surfaces. All surfaces exposed to outer side on the model, are mostly printed that sides down on the printer bed. That way, they are smooth, they would only require some polyester kit to fix some small places and/or spray filler and delicate sanding for final touch before painting.

- True scale model. All parts of the model have been modelled up to every detail as it was possible. All parts are 3D printed on FFF printer from ABS.

- Very easy assembly for most of the build. The parts are designed to fit together. Only exceptionally there is needed some sanding and surface finishing.

A full kit is also available if requested (all parts printed). Please write me a message.

More details, photos and info: https://eu.zonerama.com/jsyrovat/Album/10652878

3D printing settings

Printing: material ABS (required! I strongly recommend some good ABS, which sticks well to print bed, like Prusa Easy ABS / https://www.prusa3d.com/product/white-easyabs-filament-1kg/), layer 0.1mm, no support , no brim, 20% cooling from layer 4 upwards is recommended (or better required).

G-Code included for Prusa MK4.

742g of filament needed.

Minimum 210x250mm printer bed size required.

Note, this is a large model, there are total 36 different prints and printing time is 5 days 6 hours for TT gauge. However the construction is very easy, with some experience required (for eg. from plastic kits), and it can be completed in 1-2 weeks.

A note about price: Personally I love designing scale models and by purchasing it, it will allow me to spend more time creating another designs, instead of boring IT office work. Thank you!

/https://fbi.cults3d.com/uploaders/13583341/illustration-file/97b1ba7d-e986-46e8-b9b0-a68548892db7/Pont-ferroviaire-de-Massongex%2C-bridge-N%2C-TT%2C-H0-manual%2C-mjs2310-3D-print-kit.jpg)