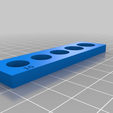

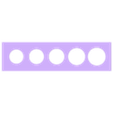

Update: Added an even smaller an simpler design that will allow you to check your slicer settings against a known diameter. 10, 10,5, 11, 11,5 an 12 mm holes. Once finished just stick some 10 mm drill into it an see how far your hole printing results differ from CAD files.

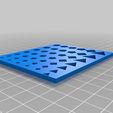

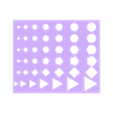

This is a overworked version of HydraRaptor´s version at: http://hydraraptor.blogspot.de/2011/02/polyholes.html . Thanks for that so far. I have reduced the dimensions by obmitting some holes and diameters. The polygons have the follwing number of vertice: 3,4,5,6,8,10. Their outer circle has 3,4,5,6,7,8 and 10 mm diameter.

Due to slicing round holes are beeing converted into polygones with a variable number of vertices. The higher the number of verticer for each circle the closer your printed hole will fit the calculated one from CAD. To control the outcome of a diameter CAD vs 3D Print, you can use this tool. It will tell you how much a given diameter in CAD will be reduced when printed. You can then either scale up your model in Repetier or any other printing software, or if that would interfere with other mechanical restrictions, scale down the diameter in your CAD drawing, so the outcome will be a close to the final diameter as possible.

Since the number of vertices that represent a circle/hole in a CAD drawing depends on the resolution that you predefine in your Slicer, you must be aware that result will greatly differ if you change slicer minimal resolution settings.

OpenSCAD script as in file:

difference() {

cube(size = [85,72,3]);

for(i = [1:6]) {

assign(v=[3,4,5,6,8,10][i - 1]) {

assign(shrink = cos (180 / v)) {

echo(v,shrink);

for(d = [3:9]) {

translate([d * d - 4 - ((v == 3) ? 3 : 0), 11.2 * i-2, 0])

cylinder(h= 20, r = (d/2)/shrink, $fn= v);

}

}

}

}

}

Enjoy !

If you like, visit my blog:

http://3dptb.blogspot.com

Deutsche Version:

Eine Problematik, die beim 3D Drucken, ist die Untermassigkeit von Löchern.

Dies liegt an der späteren Aufbereitung durch den Slicer. Dieser wandelt Kreise in recht grobe Polygone um, so dass - abhängig vom Kreisdurchmesser eine Verengung entsteht. Diese ist nicht linear, sondern abhängig vom Durchmesser bzw. von der Anzahl der Facetten.

Am besten mal diese Objekt drucken und dann nachmessen wie viel sie tatsächlich dann haben.

Die Polygone haben 3,4,5,6,8 und 10 Kanten und die Umkreise dieser Körper 3,4,5,6,7,8 und 9 mm Durchmesser. Die Umkreise der Polygone entsprechen denen, in der CAD erstellten Löchern.

Nach dem Druck misst man beispielsweise mithilfe von Bohrern bekannter Größe nach, ab wann (ab wieviel Polygonen statt eines Kreises also) die Durchmesser stimmen.

Den Korrekturwert verwendet man dann um entweder im Druckprogramm runter zu skalieren, oder im CAD den Durchmesser hoch zu skalieren (was nicht immer möglich sein dürfte)

Das führt dazu, dass man entweder die korrekten Innendurchmesser designt und später dann die Bohrung aufreibt/aufbohrt, oder von vornherein die Innendurchmesser angibt, die dann dem Druckergebnis entsprechen. Dann ist die Zeichnung allerdings für andere Bearbeitungen wie CNC etc. nicht mehr geeignet, da die Durchmesser zu groß werden.

Das Ganze ist also ein Softwareproblem. Außendurchmesser (z.B. bei Röhren) sollten übrigens immer stimmen, d.h. CAD und 3D Print sind (abgesehen von anderen Einflußfaktoren) gleich.

Besuch mal mein Blog:

http://3dptb.blogspot.com

/https://fbi.cults3d.com/uploaders/22000791/illustration-file/dbb34bea-11e6-4a94-a6e7-a64f1c266699/3D-Print-Holes-Calibration-3.png)