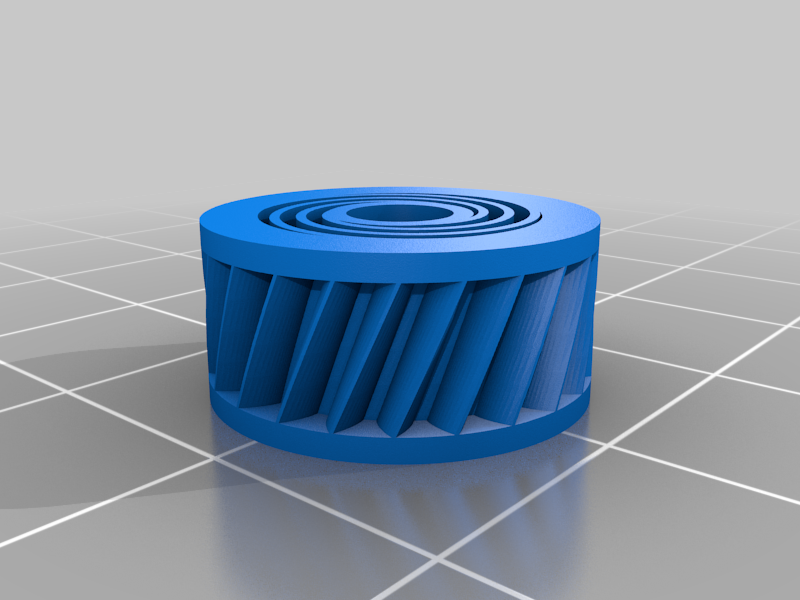

This tumbler can be mostly printed, and you probably the other required parts are easily found or salvaged. The support can extend and shrink to adjust to various jar dimensions, so that you only need to print a gear belt for each jar. The distance between wheels / gears should be adjusted to be large enough to keep the jar in place, without excessive pressure.

I built this to experiment with 3d printed part smoothing, so far I have mixed results : it takes days to see a difference, probably because the parts are very light so the friction is very gentle, and sharp corners tend to be rounded. But maybe it can be better suited for other purposes...

All you need is:

- a small electric motor (e.g. the tray opening motor from an old cd/dvd drive)

- a power source

- a jar with appropriate dimensions for the items to be polished

- some abrasive, such as silicon carbide

Some of the parts are customizable to fit the motor and jar dimensions, you will need to customize at least:

- the motor support (to fit the motor diameter)

- the pinion (to fit the motor shaft diameter)

- the jar gear (to fit the jar outer diameter)

- the paddles that go inside the jar

This can be done with the OpenSCAD customizer after installing this gears library (https://www.thingiverse.com/thing:1604369). Gears do not render in Thingiverse customizer as the library is not installed. Also, many other parameters can be easily changed in the source code if needed.

Instructions

First, choose a motor to power the tumbler. I used an old cdrom drive tray motor. I have no idea of its specifications, but its diameter is 23.8mm, its height is 12mm and its rotation speed seems to be around 4000 rpm at 3V (the lowest transformer voltage that I have), with a power consumption of about 0.2W with a tiny jar.

Depending on the motor rotation speed and the desired jar size and rotation speed, the number of teeth of the "large_gear" part can be changed to adjust the reduction ratio. I found that two turns per second is reasonable for a very small jar (5cm diameter).

Print the required parts:

- 1x axial_bar

- 2x transversal_bar

- 2x wheel (or wheel_solid)

- 2x small_gear (or small_gear_solid)

- 4x support_1

- 3x support_2

- 1x support_2_motor (customized)

- 1x large_gear (optionally customized)

- 1x pinion (customized shaft diameter)

- 1x jar_gear (customized)

- 3x jar_paddle (customized)

All parts print without support, but a low speed is advised to ensure the teeth are as precise as possible. Almost no post-processing is required except some filing for adjusting the shafts to the holes. Assembly is straightforward. The support parts snap together with a wheel or small gear in-between, gluing is also possible. The pinion should be glued on the motor shaft (otherwise it will become loose after some time). The jar gear can be glued if it's too loose. The paddles are glued inside the jar.

PLA works well (maybe a lower friction material such as PETG would be better). The curved beams for wheels and gears are supposed to give some elasticity to the wheels and gears but they are fragile, can be difficult to print right, and it's still quite noisy, so the solid version can be used instead for simplicity. I also put some oil to lubricate the moving parts. Once everything is assembled and powered, watch the barrel rolling and be patient...

/https://fbi.cults3d.com/uploaders/31951251/illustration-file/155ac39e-7315-41f1-a04e-eccc6a0e0d6f/20200622_0001.jpg)