Update 30-APR-2017: I added the config file that I’ve been giving to people who ask for my config file. The configuration enclosed is the original 5 button configuration file of SkynetV2.3.1 modified to support 3DTouch/BLTouch. Note that this is for SkynetV2.3.1.

--- End of update ---

The 3DTouch/BLTouch sensor is a servo based sensor. Its main advantage is that it allows you to easily move between printing on glass or directly on the bed, without having to adjust auto leveling parameters. This sensor requires an additional pin that isn’t easily available on the Anet V1/Sanguinololu control board. To use this sensor on an Anet A8, you either have to move to a different board, modify the LCD cabling (see http://www.thingiverse.com/thing:2091529), or free up a pin on the Anet board by converting the display to I2C. See my design for freeing up a pin: http://www.thingiverse.com/thing:2098646 .

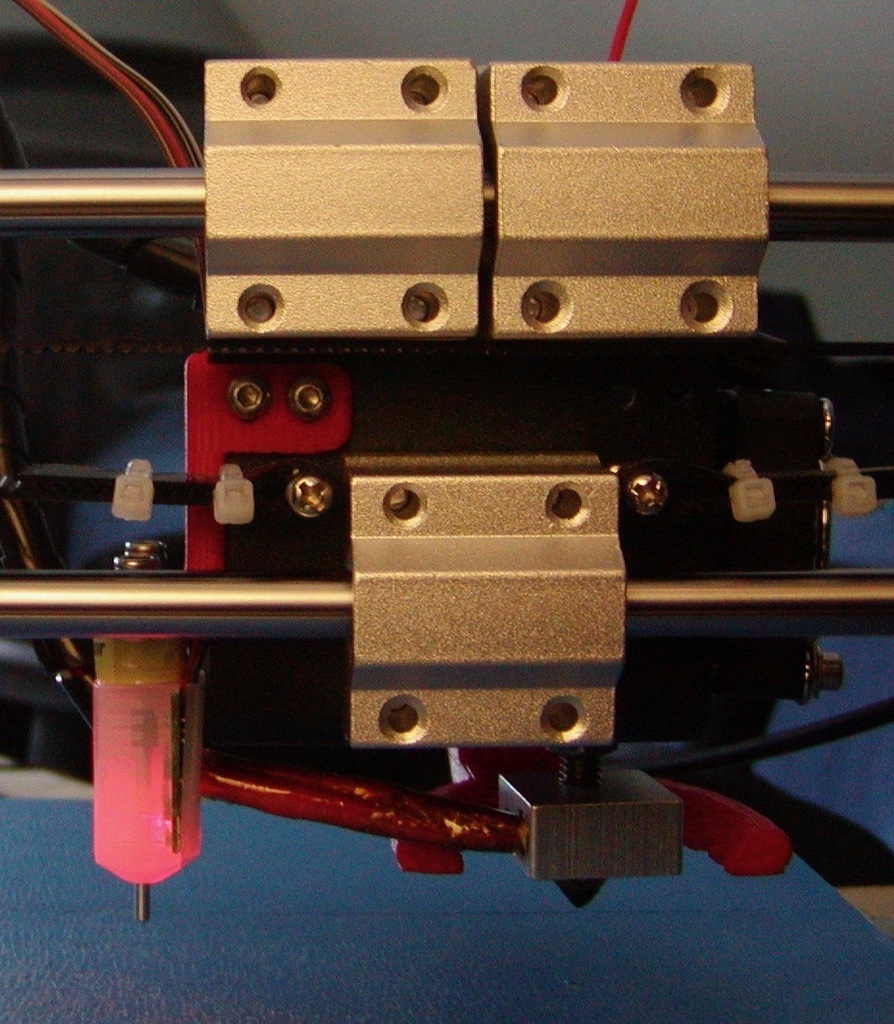

There are several 3DTouch brackets available on Thingiverse. Most won’t fit the Anet A8. The one that I found that would probably fit (http://www.thingiverse.com/thing:2084025 ) moves the sensor so that it’s almost in line with the fan, and it’s right next to the extruder cooling fins. This limits the bed area available to the probe in the Y direction. My design limits the X direction, but less than the limitation of the design that limits the Y direction.

My design will only work on Anet A8s that have the same hole pattern on the extruder carriage as mine. This is a very tight fit. It should not touch anything and is greater than the manufacturer's minimum suggested distance of 15mm from the hot end/nozzle.

Prints: SensorBracket.stl, AlignmentSpacer.stl

I printed both at 100% fill, 0.1mm, support “Touching Bed". I’m not a print settings expert, but I figured the bracket needs to be as rigid as possible. The alignment spacer is the distance from the base of the sensor to the bed when the nozzle is a paper thickness above the bed. The spacer is only as precise as your printer. Mine was dead on (today). It should measure 8.3mm on a good day.

Mount the sensor on the bracket before attaching the bracket to the extruder carriage.

Use Repetier-Host, Cura, etc., to place the nozzle the thickness of a sheet of paper off the bed. Use the alignment widget to set the height of the sensor above the bed.

Some of the Marlin/SkynetV2.3.1 Configuration.h settings: (the others you can get from the manufacturer’s documentation)

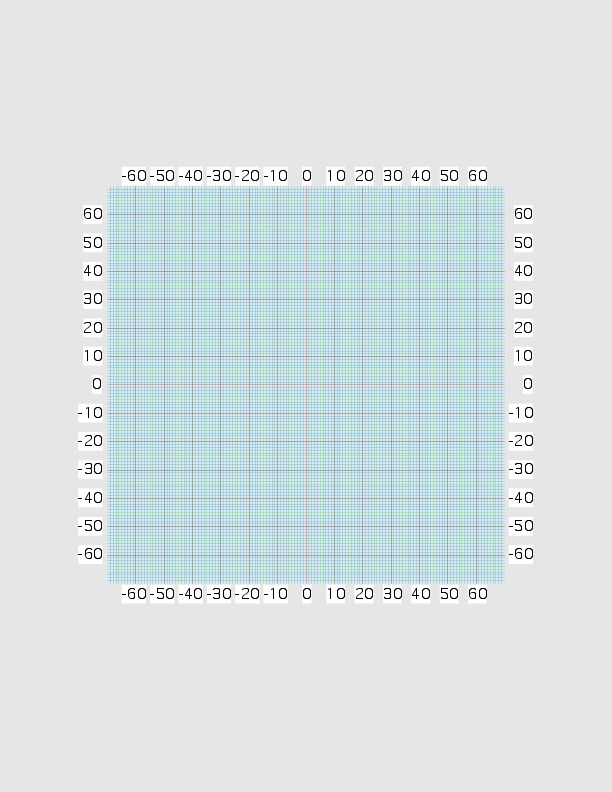

I determined these two offsets using the grid file "Coords mm.pdf"

define X_PROBE_OFFSET_FROM_EXTRUDER 59 // X offset: -left +right [of the nozzle]

define Y_PROBE_OFFSET_FROM_EXTRUDER 14 // Y offset: -front +behind [the nozzle]

The Z_PROBE_OFFSET_FROM_EXTRUDER setting should be set based on your actual results you measure during setup.

define LEFT_PROBE_BED_POSITION 15

define RIGHT_PROBE_BED_POSITION 195

define BACK_PROBE_BED_POSITION 205

define FRONT_PROBE_BED_POSITION 25

If you use a non-standard servo pin you’ll need to define SERVO0_PIN. In my case it’s 27.

define SERVO0_PIN 27

DO NOT attempt to do an Auto Home after your very first upload. Send one of the test gcodes to make sure you're connected.

M280 P0 S10 ; pushes the pin down

M280 P0 S90 ; pulls the pin up

M280 P0 S120 ; Self test – keeps going until you do pin up/down or release alarm

M280 P0 S160 ; Release alarm

Hardware: (2) M3 x 8, (2) M3 x 12, (4) M3 nuts

/https://fbi.cults3d.com/uploaders/31968667/illustration-file/dfab2ced-4cf5-417a-bc0b-0653ba3065ec/P2240011.jpg)