3D model description

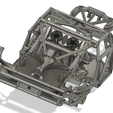

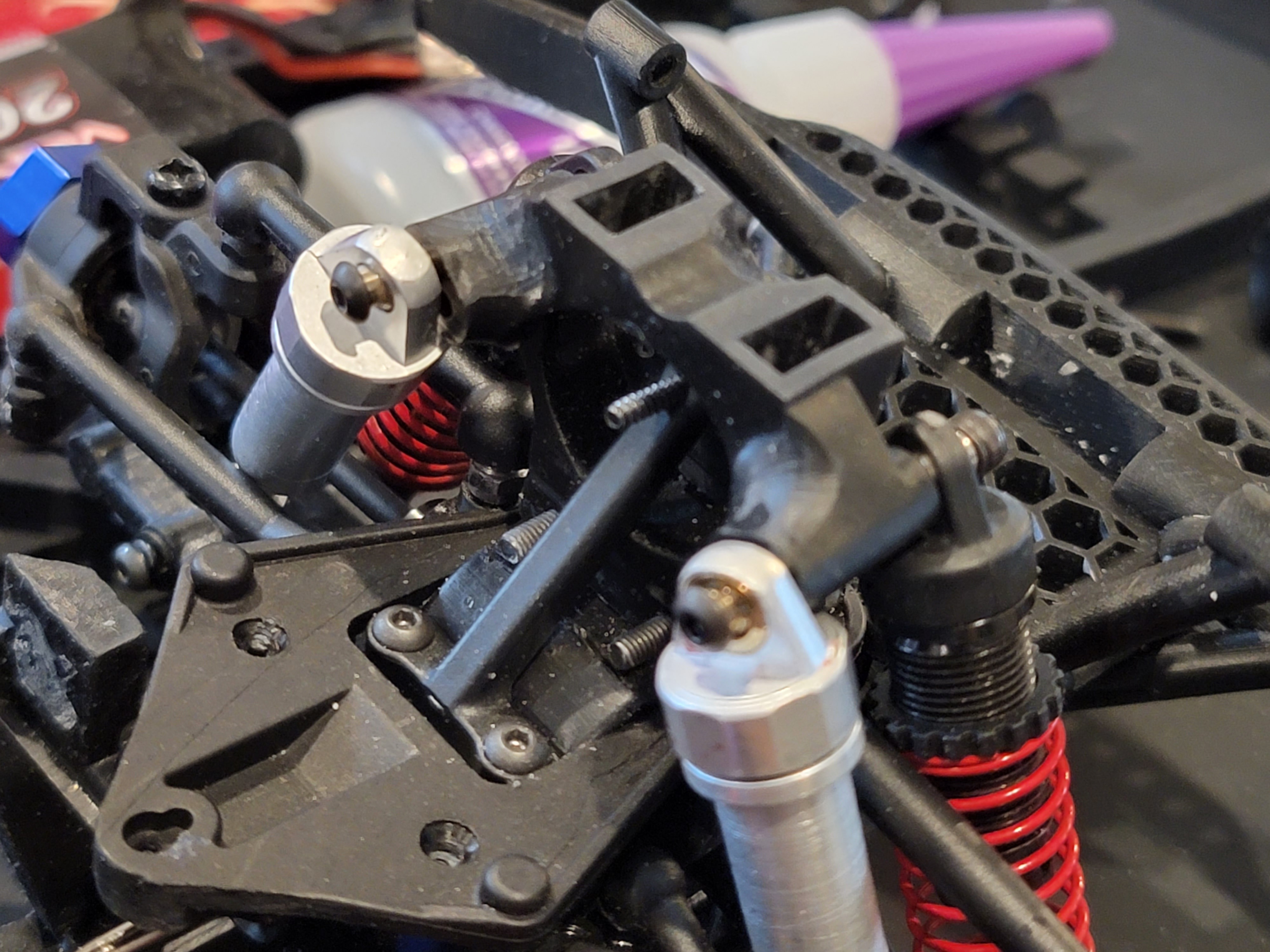

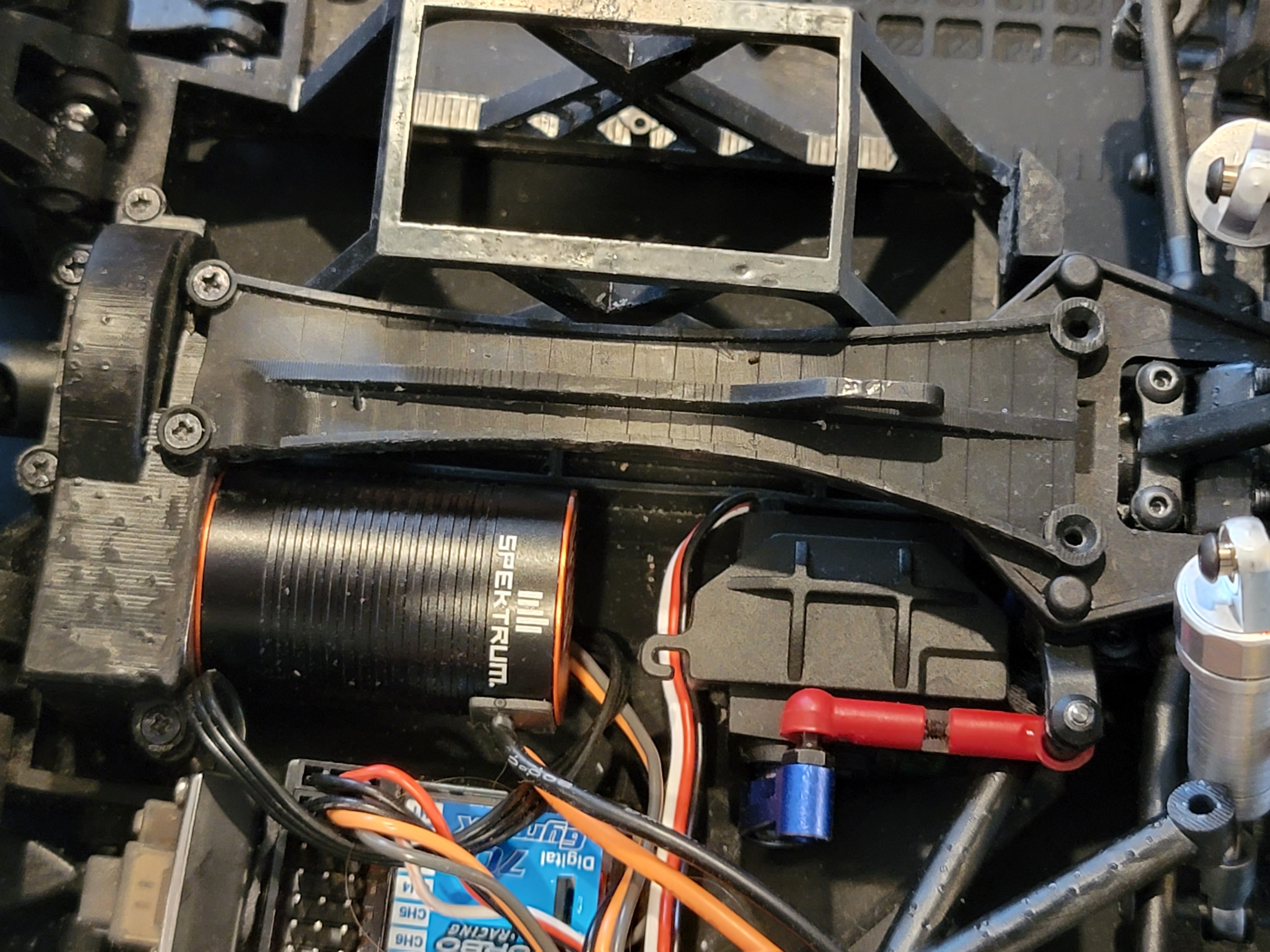

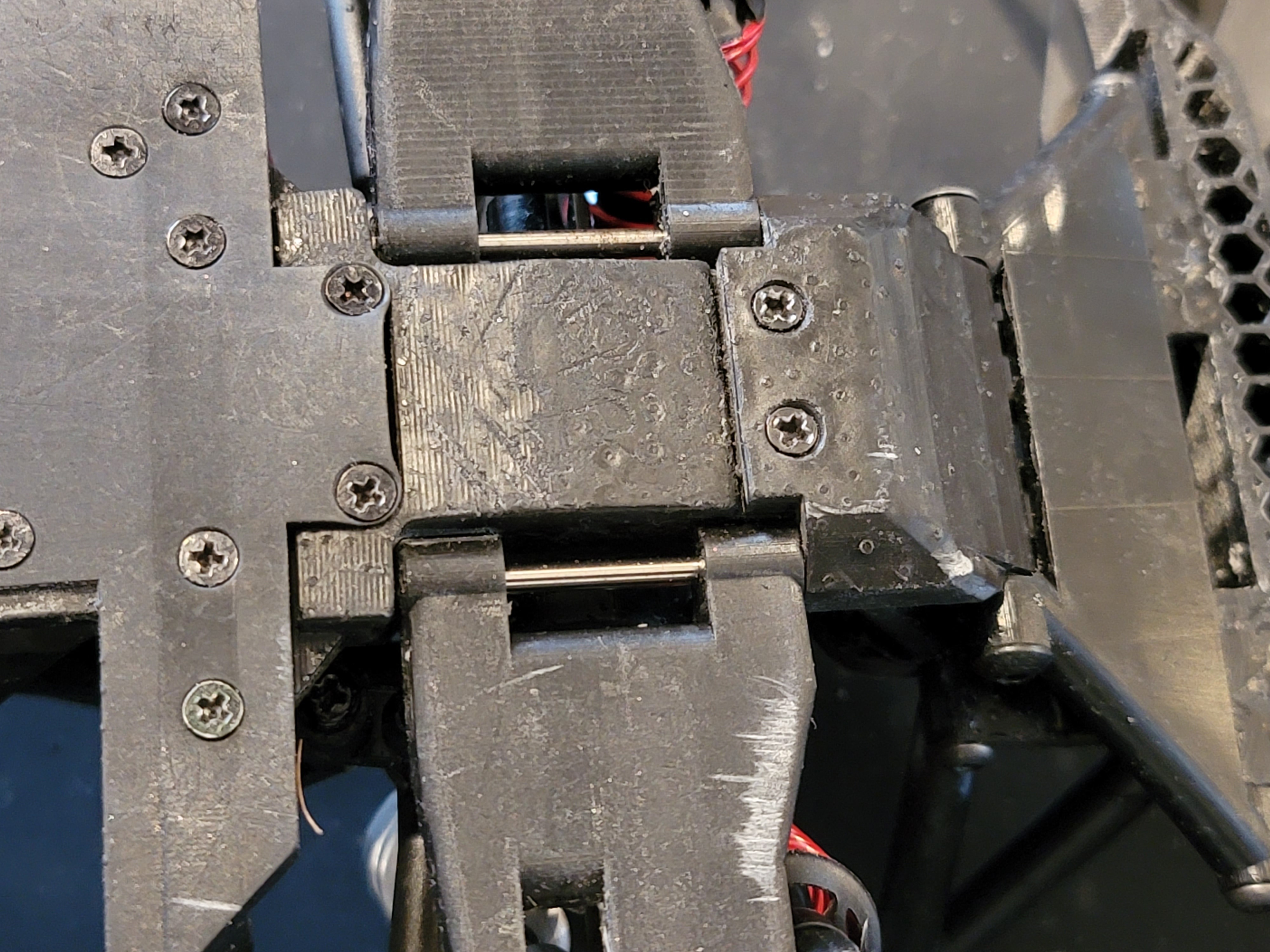

UPDATE** I added in a new chassis to accommodate the use of the Mini E-revo center Gearbox. and new center brace for this chassis. Due to size constraints it is a very tight fit and the stock VXL-3M ESC will sit directly below the motor with only approx .5-1 mm of space between them. There is a design for the motor plate that you will need to use. The stock motor plate does not work. it can be printed but will not be that strong so may be a weak point. I would recommend cutting one out of a 2mm aluminum plate using the 3d print as a template. or send to a shop to have one cut for you. I will be cutting some from aluminum that will be available for purchase separately on my etsy store. I also updated the front Mount after testing and breakage of the original design.

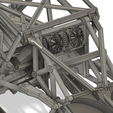

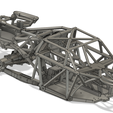

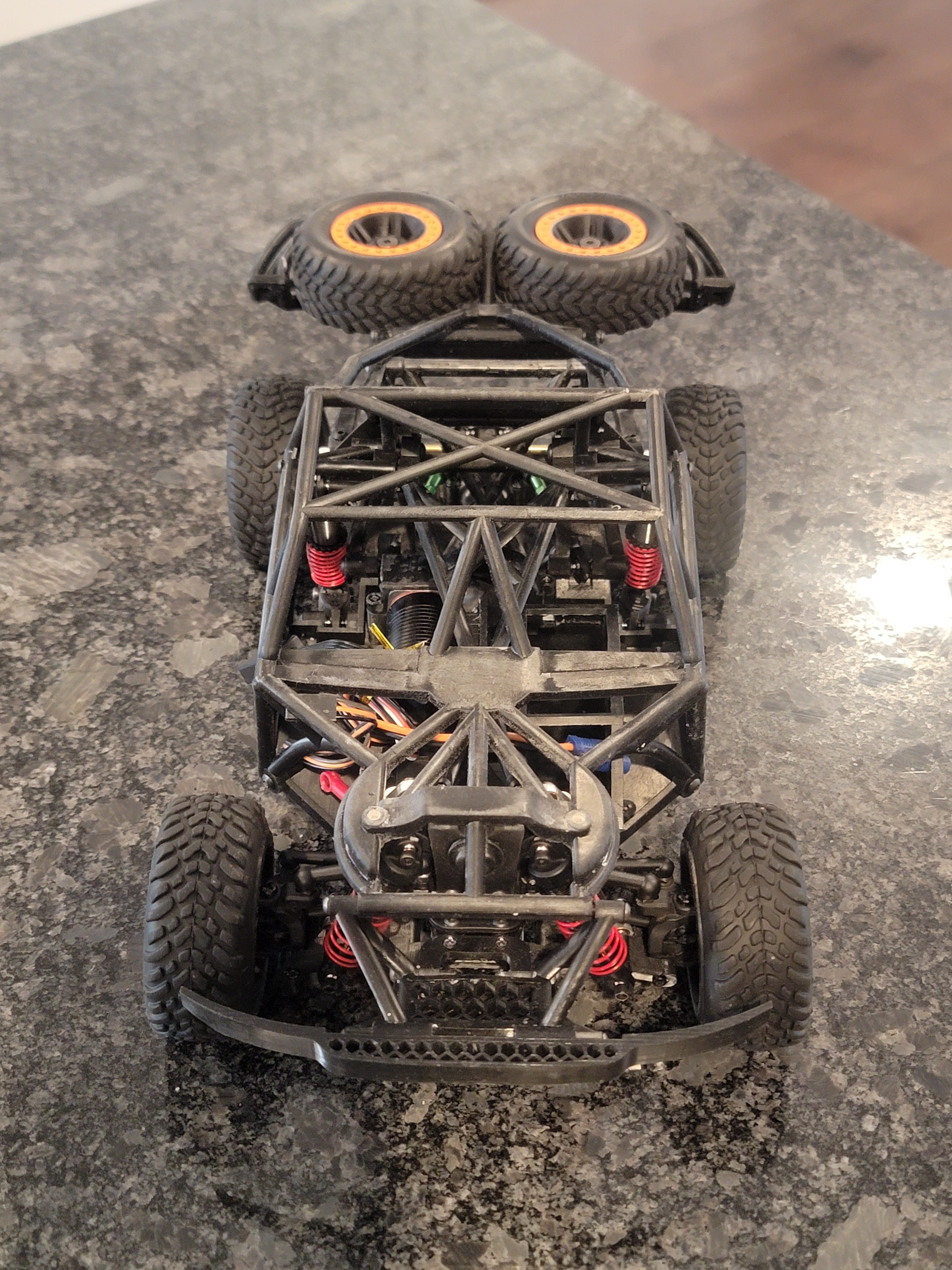

This is designed to be a 1/16 scale Trophy Truck. This design uses

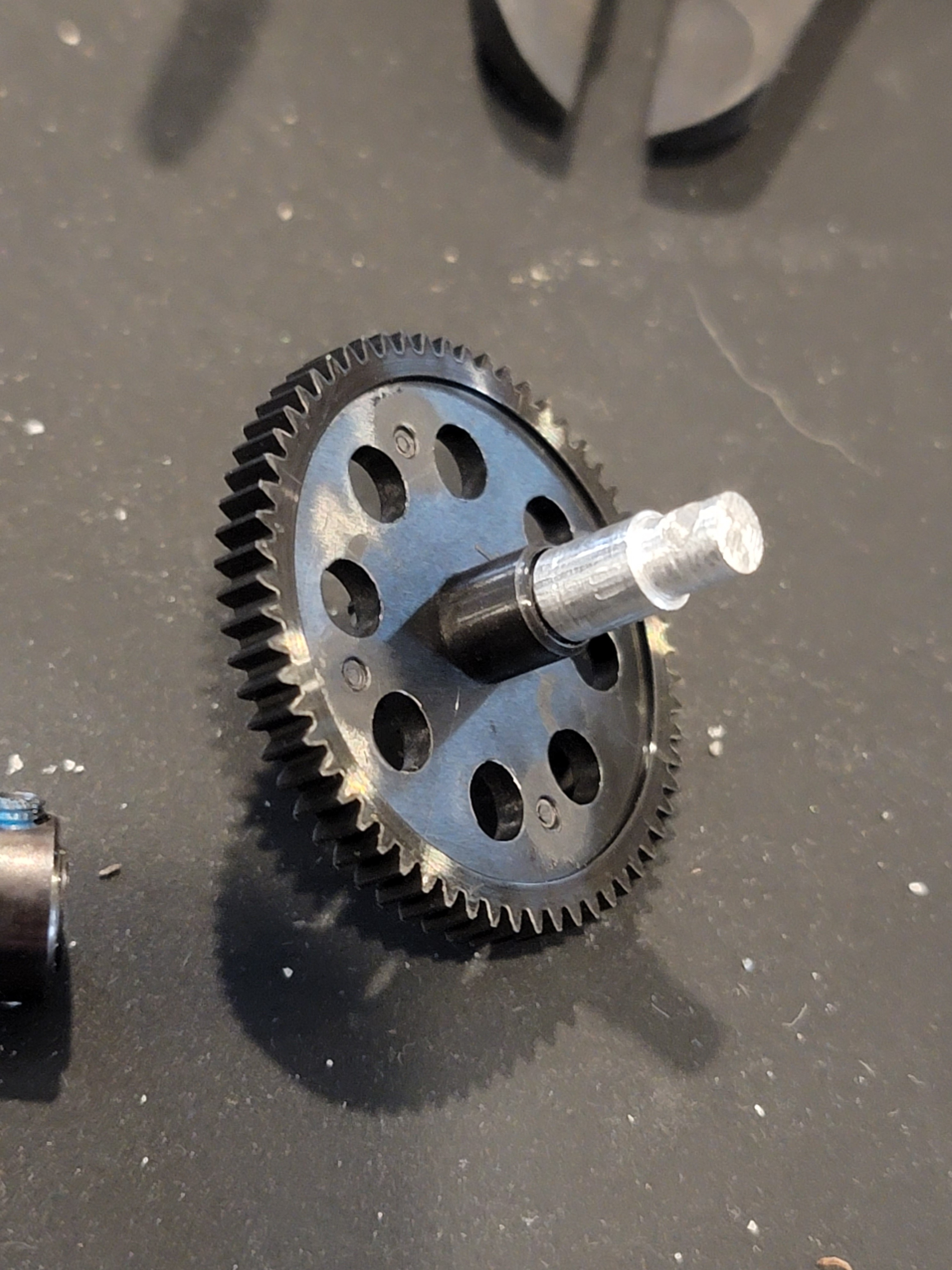

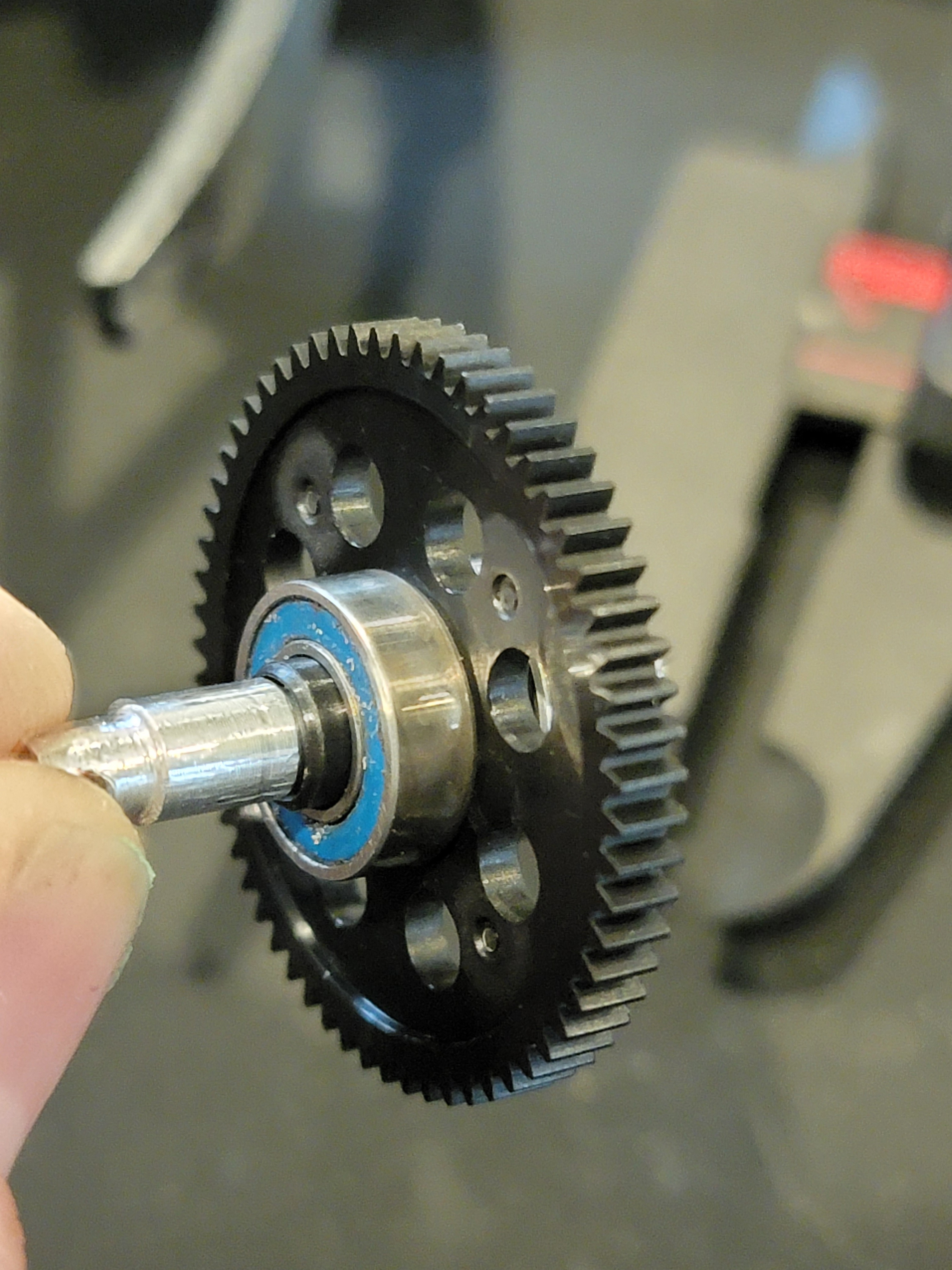

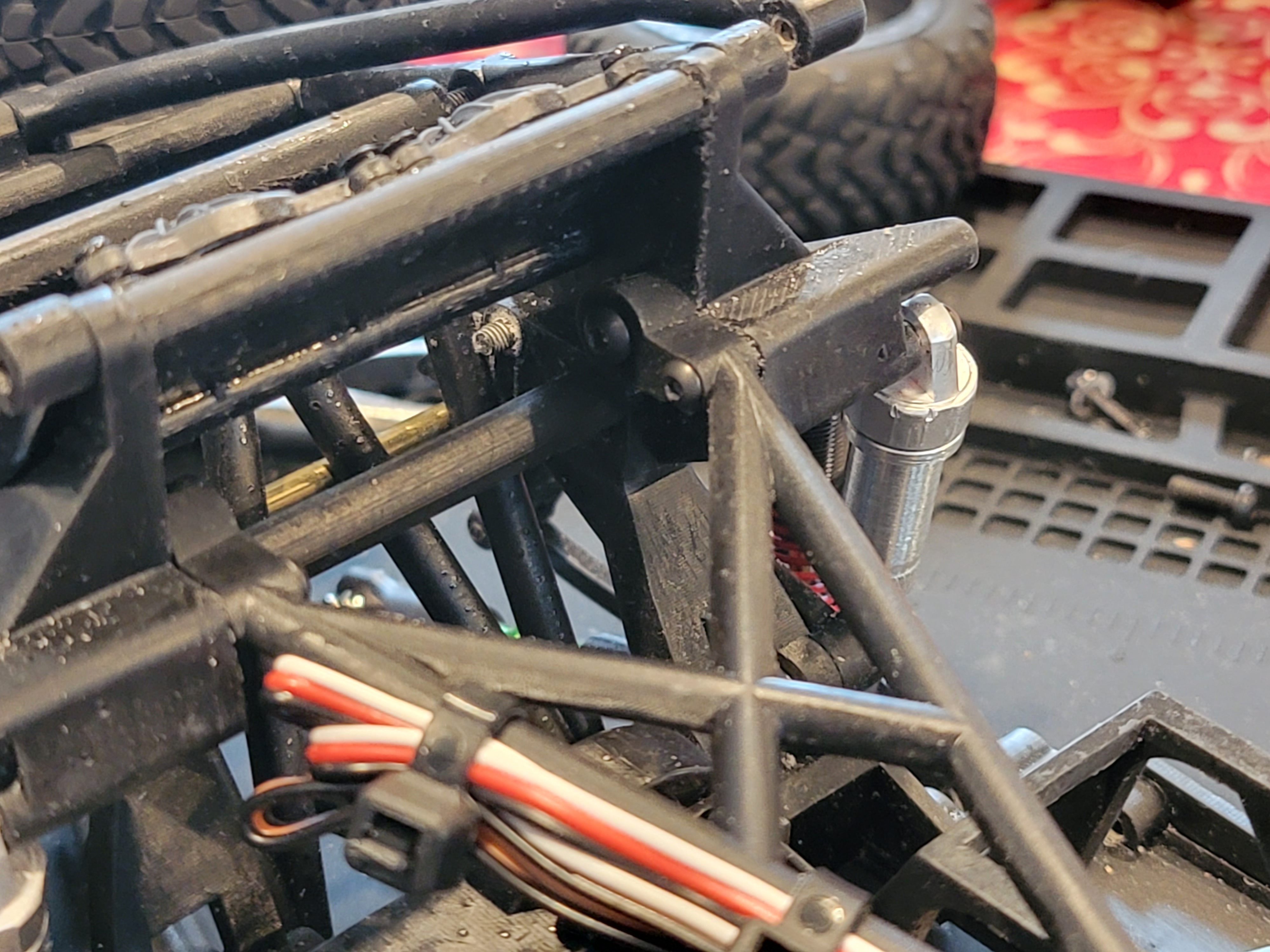

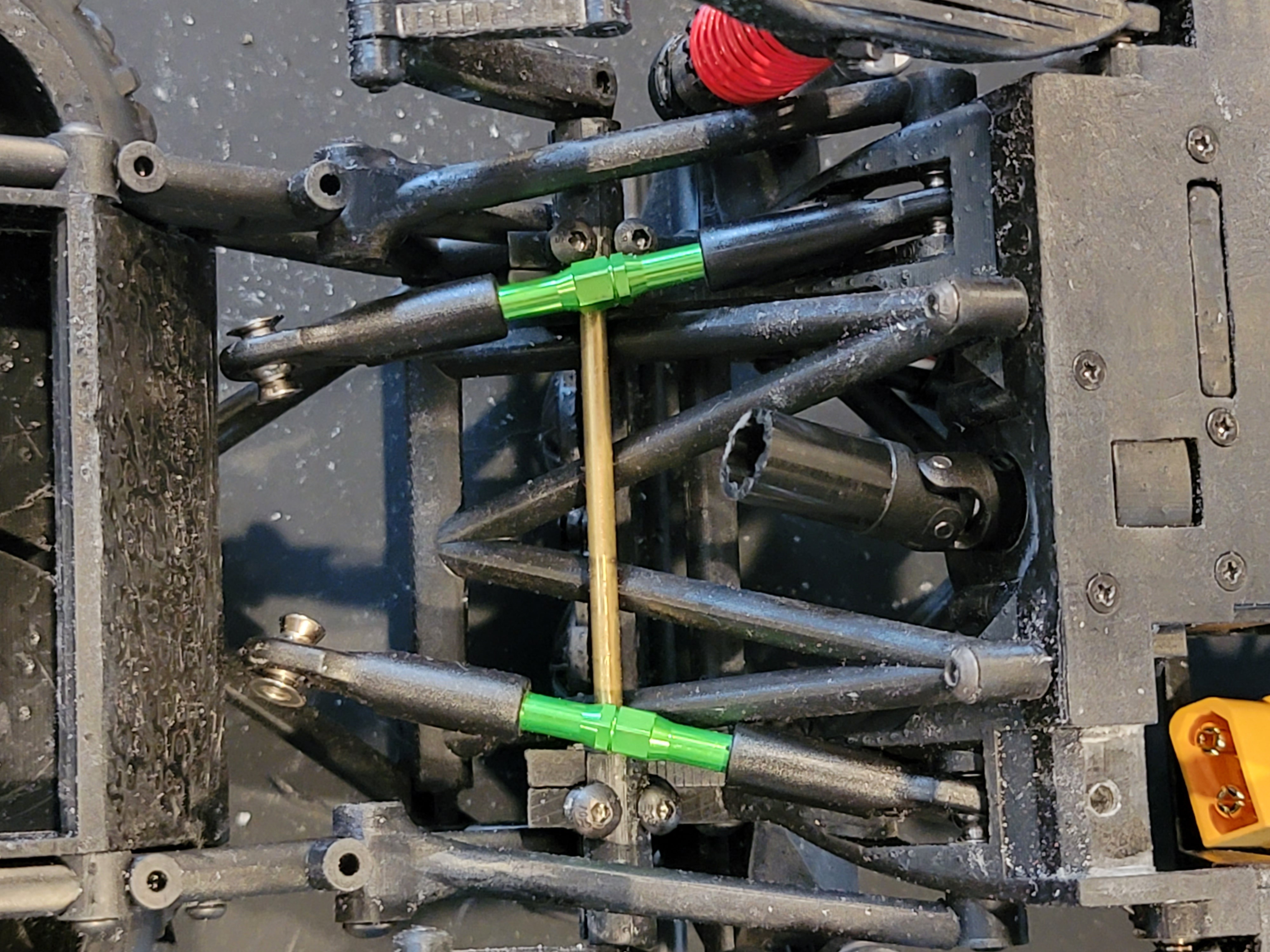

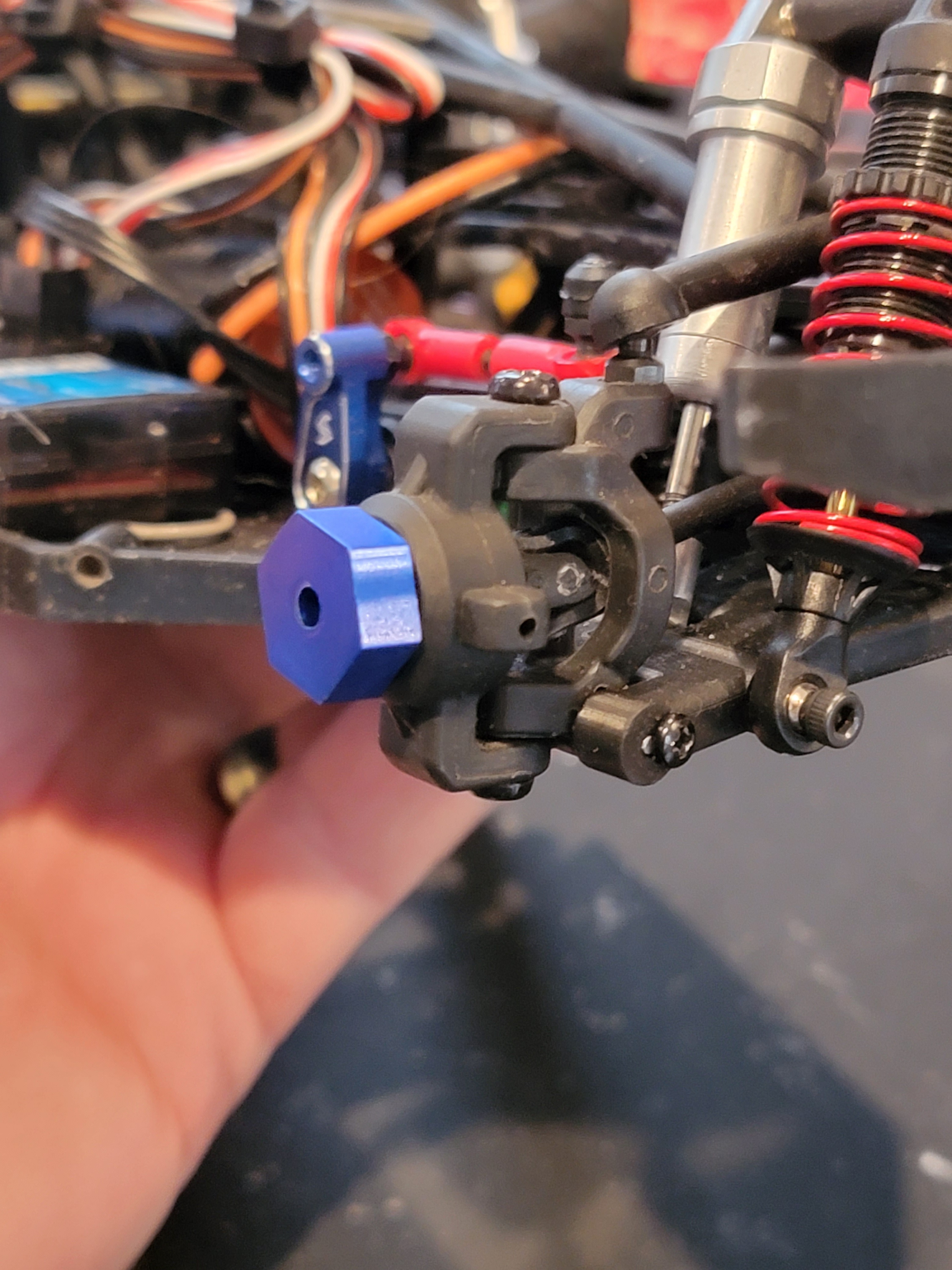

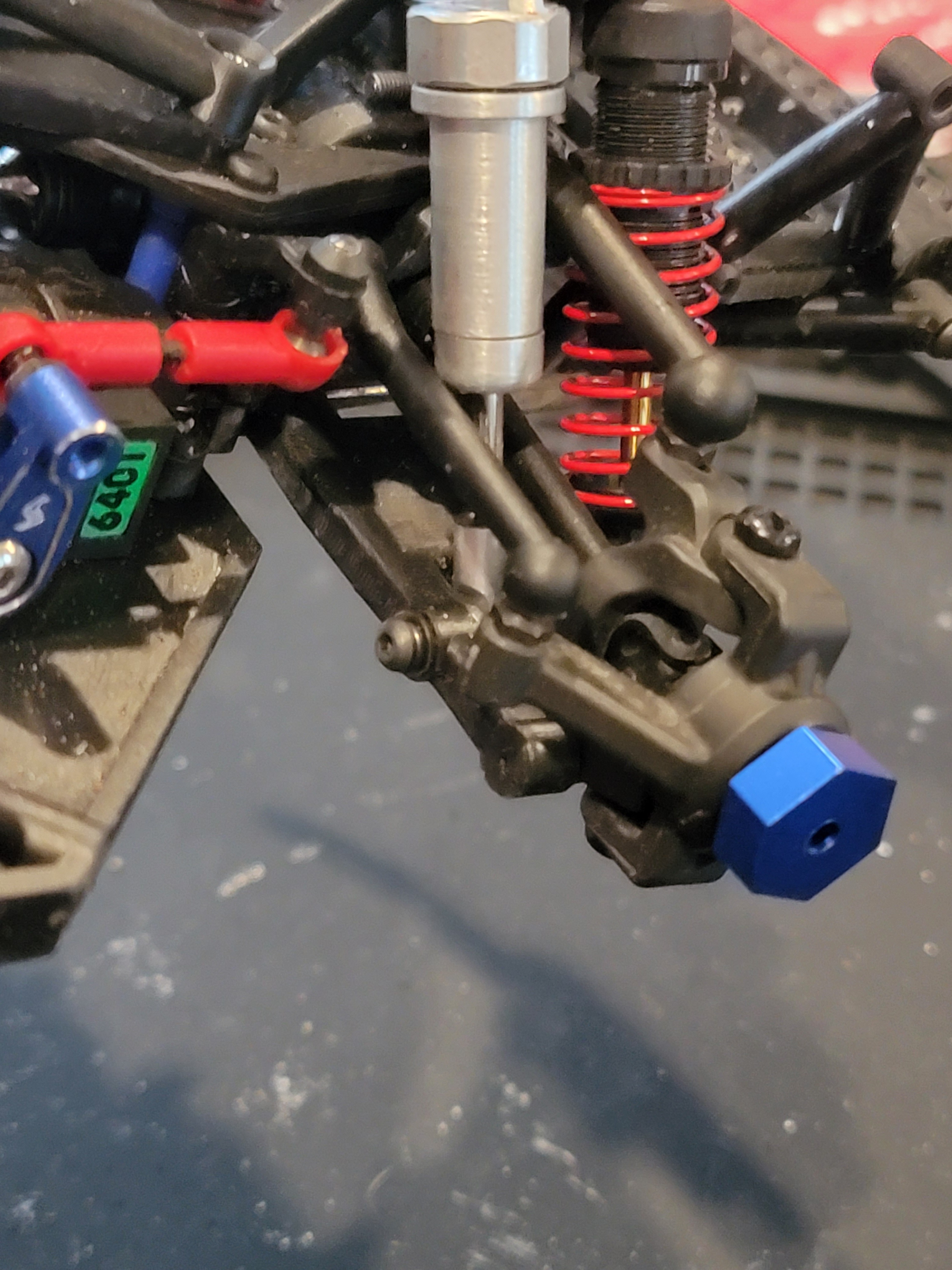

Traxxas mini e-revo front and rear differentials, drive Cups, and drive shafts, The drive shafts are reversed on this so the rear is the front and the front becomes the rear. It also uses the metal axles for a Latrax Prerunner, as well as front links, knuckles, carriers, and some steering components. The one steering link is replaced with one of the designed ones. it also uses the latrax motor plate. Does require some custom work for the center spur gear. This uses multiple 2.5mm and 3mm screws of various lengths. also uses Traxxas latrax GTR shocks or aftermarket shocks for the latrax teton, To make the dual shock set up you will need one set of aluminum shocks off Amazon or such. you will need to fill off the threads and remove the spring to allow them to fit accordingly. This truck also uses the 1/16 Traxxas Slash Body and tires.

You can get a doner Latrax Prerunner or Teton for some of the parts.

TRA parts

7543X

7078 (X2)

7079 (X2)

7019 (X4)

7538X

7540X (X2)

7636

7532

7650

7669

7533

7623

Latrax spur gear

7755 (requires cutting and modifying)

7071 (x2)

7529

7590X

7012R

7052 (x2)

7250R modified cut down in length for the rear driveshaft.

Amazon purchased. Kindroufly 562 piece screw kit- M2.5 and M3

Optional 7250R only using the long driveshaft

Pinion gear for the front.

3D printing settings

You should be able to print this on any type of printer. I made most test pieces on my FDM printers. There is a lot of supports. Durability and strength of the model will depend on the material you use and your print settings. The diff case, rear, and transmission case will need to be lower layer height as they need a high level of detail required.

Most test pieces were printed on my prusa XL. I used petg. I would recommend something like nylon carbon fiber for both impact durability and strength. My final product and the one in the pictures I used Resin (SLA) I used a mixture of Resione F69 and Conjure Tough resins. Bumpers are a 50/50 mix, remaining pieces are a 70/30 mix. 70% Tough and 30% F69

/https://fbi.cults3d.com/uploaders/21885783/illustration-file/d6d55543-67af-4845-8aed-a5f298aa5611/20231224_124954.jpg)