Este diseño es una segunda versión de cable directo subida por mí, pero esta vez usando cadenetas en vez de tubo corrugado.

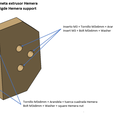

El diseño actual está pensado para usar en una maquina con extrusor Hemera instalado, pero se puede adaptar fácilmente a cualquier extrusor simplemente cambiando la pieza "Hemera_drag_chain_support", de fácil diseño.

El tubo corrugado se acaba rompiendo por el uso. La cadeneta es una solución mucho más robusta.

Los cables de cinta que vienen con la Artillery X1 dan muchos problemas, hay 7 conectores y 3 placas base entre los componentes y la placa electrónica. Además, la sección de los cables no está bien dimensionada. Este diseño soluciona todos esos problemas. Se eliminaban las 3 placas PCB y se dejan solo los conectores de inicio y fin, por lo que hay un cable directo del componente a la placa. Además, es muy fácil añadir más cables ya que la cadeneta tiene espacio para mas cables, y al ser abierta, se pueden añadir mas cables de forma muy simple.

Los conectores se pueden extraer de las placas PCB y soldar, o se pueden adquirir unos específicos para cables. En mi caso se han usado los de la placa.

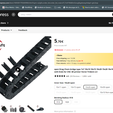

La cadeneta usada que se ha usado es la siguiente (opcion 20x10mm open, comprar dos metros):

https://www.aliexpress.com/item/1005001795469984.html?spm=a2g0o.order_list.order_list_main.47.21ef194dKmGoog&gatewayAdapt=glo2esp

Se usan muchos tornillos de métrica 3, se recomienda comprar el siguiente kit:

https://www.amazon.es/gp/product/B0C7MBB6HM/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

Los insertos usados son los siguientes:

https://www.amazon.es/ruthex-Inserto-casquillos-roscados-RX-M3x5-7/dp/B08BCRZZS3/ref=asc_df_B08BCRZZS3/?tag=googshopes-21&linkCode=df0&hvadid=435812925325&hvpos=&hvnetw=g&hvrand=9966281900493803901&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=1005547&hvtargid=pla-925706318765&psc=1&mcid=04d2d004c80d378796507b1e3cbd97e5&tag=&ref=&adgrpid=101606058376&hvpone=&hvptwo=&hvadid=435812925325&hvpos=&hvnetw=g&hvrand=9966281900493803901&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=1005547&hvtargid=pla-925706318765

Los cables tienen que ser de sección awg 24 (0.25 mm2) o superior.

Los dos cables de la resistencia (Heating block) tienen que ser de awg 20 (0.5mm2) o superior.

Las longitudes de las dos cadenetas son:

• Eje Z: 39 eslabones + dos extremos

• Eje X: 30 eslabones + dos extremos

Las piezas se han impreso en PETG, pero se puede usar PLA.

Los parámetros de impresión usados son:

• Boquilla 0.4mm

• Ancho de linea 0.4 mm

• Altura de capa: 0.3mm

• soportes: SI

• Relleno: 100%

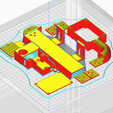

Hay que imprimir todas las piezas x1, excepto el soporte de cadeneta de la upper box que se tiene que imprimir dos veces.

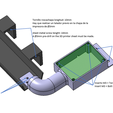

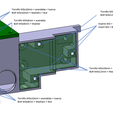

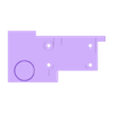

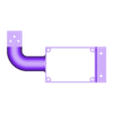

Tornillería: ver fotos adjuntas

video:

https://www.youtube.com/watch?v=Qr6Jgt_W3yo

This design is a second direct cable version uploaded by me, but this time using chains instead of corrugated tube.

The current design is intended for use on a machine with a Hemera extruder installed, but can easily be adapted to any extruder by simply changing the easily designed "Hemera_drag_chain_support" part.

The corrugated tube ends up breaking due to use. the chain is a much more robust solution.

The ribbon cables that come with the Artillery X1 cause a lot of problems, there are 7 connectors and 3 motherboards between the components and the electronic board. Furthermore, the section of the cables is not well dimensioned. This design solves all those problems. The 3 PCB boards were eliminated and only the start and end connectors were left, so there is a direct cable from the component to the board. Plus, it's very easy to add more cables since the conduit has plenty of room.

The connectors can be removed from the PCB boards and soldered, or you can purchase specific ones for cables. In this case those on the plate have been used.

The used drag chain bridge that has been used is the following (buy two meters):

https://www.aliexpress.com/item/1005001795469984.html?spm=a2g0o.order_list.order_list_main.47.21ef194dKmGoog&gatewayAdapt=glo2esp

Many metrics 3 bolts have been used, so it is recommended to purchase the following kit:

https://www.amazon.es/gp/product/B0C7MBB6HM/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

The inserts used are the following:

https://www.amazon.es/ruthex-Inserto-casquillos-roscados-RX-M3x5-7/dp/B08BCRZZS3/ref=asc_df_B08BCRZZS3/?tag=googshopes-21&linkCode=df0&hvadid=435812925325&hvpos=&hvnetw=g&hvrand=9966281900493803901&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=1005547&hvtargid=pla-925706318765&psc=1&mcid=04d2d004c80d378796507b1e3cbd97e5&tag=&ref=&adgrpid=101606058376&hvpone=&hvptwo=&hvadid=435812925325&hvpos=&hvnetw=g&hvrand=9966281900493803901&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=1005547&hvtargid=pla-925706318765

The cables must be of section AWG 24 (0.25 mm2) or higher.

The two resistor cables (Heating block) must be AWG 20 (0.5mm2) or higher.

The lengths of the two chains are:

• Z axis: 39 links + two ends

• X axis: 30 links + two ends

The parts have been printed in PETG, but PLA can be used.

The printing parameters used are:

• Nozzle 0.4mm

• Line width 0.4 mm

• Layer height: 0.3mm

• supports: YES

• Filling: 100%

All parts need to be printed x1, except the top box chain holder that have to be printed twice.

Screws: see attached photos

video:

https://www.youtube.com/watch?v=Qr6Jgt_W3yo

/https://fbi.cults3d.com/uploaders/26766530/illustration-file/76adbe77-443e-4866-bde4-b55dcfe6cd7b/119a0754-812f-4698-afbc-3e03fc39df67.jpg)