PETG Glass Profile: Print ICE Cubes X1C P1S

PETG Glass Profile: Print ICE Cubes X1C P1S

Print Profile(2)

Description

I AM NOT RESPONSIBLE FOR CLOGS OR DAMAGE TO YOUR TOOLHEAD, USE AT YOUR OWN RISK!

If you give a low rating, please explain why, what you changed (if anything), list the filament youre using, if you dried it, and how you started the print (Bambu Studio ONLY), and post pictures so I can help you.

Dont leave a 1 star review with no explanation, thats toxic and looks bad on the profile. I do respond to everyone so please dont be toxic.

The other models in the pictures are not my models, I used them to test out transparency!

This was tested on an X1C.

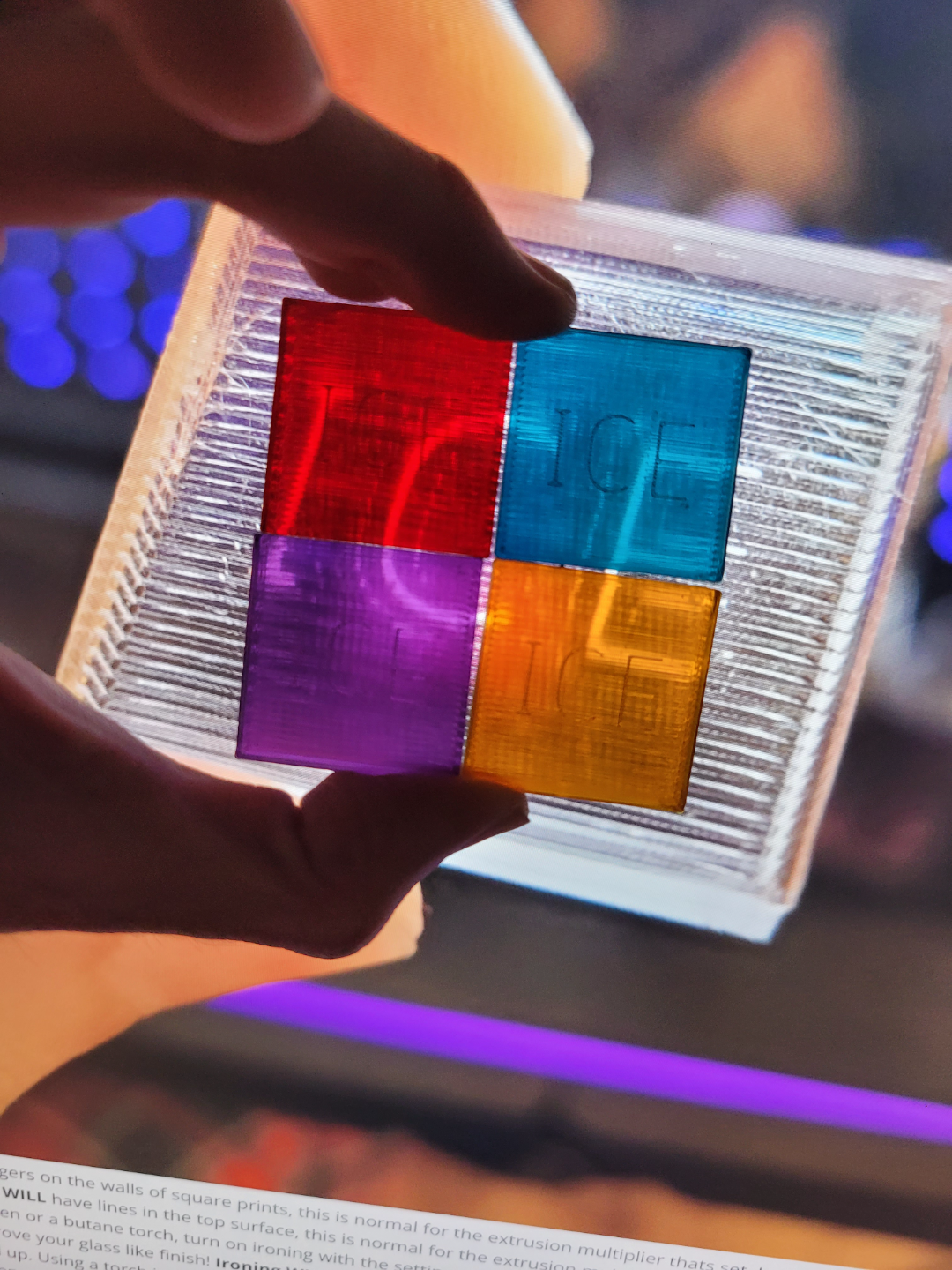

Good for stained glass prints!

You ever wanted to print glass? Well its not glass but its close enough.

With this profile, you can print ICE cubes, you can also use this profile to print very transparent 3D models, but theres some rules you HAVE to follow:

P.S. You can try using transparent colored filament as well. It wont look as transparent as clear but you can do some stuff with it. IC3D is what I use for filament, links are in the rules below. Also for A1 Series and non Bambu printers, copy the values from Bambu Studio on this profile to your slicer, or if your using Bambu Studio with A1 Series or your non Bambu printer, just copy all settings over using 2 windows.

- DO NOT RUN THIS PROFILE OFF THE BAMBU HANDY APP ON YOUR PHONE. ONLY USE BAMBU STUDIO. The Bambu Handy app cannot read custom profiles.

- Restart your printer (power off for 5-10 seconds and power back on) before using this profile, ive had weird issues with the X1C deciding to put lines through the x and y axis on each layer as if the extrusion multiplier kept dropping as I continued to reprint for testing purposes even though it was set properly.

- Leave ALL settings alone unless you know what youre doing. I mean this in the most literal way. I dont want you changing settings then complaining that it didnt work or it clogged on you, because the problem is on you at that point.

- DO NOT SWITCH THE PRINTER PROFILE, print it as it sits on the printer its configured for, this profile will warn you that its not the right printer if youre using an X1C. Ignore the warning and print it anyway. Switching the printer profile will cause you to lose everything this profile is.

- DO NOT SWITCH THE FILAMENT PROFILES, print it as it sits but select the filament you want to use to print with whether its in the AMS or stand alone.

- SAVE THE PRINTER PROFILE, PRINT PROFILE, AND THE FILAMENT PROFILE as soon as you open it so you have them for later. You can name them all “ICE Profile” or “Glass Profile” or whatever you feel.

- THIS IS TUNED FOR A HARDENED STEEL .4 MM NOZZLE. If youre using stainless or brass, dont complain to me if its over extruding or under extruding. Youll have to tune your extrusion multiplier yourself to get the results you want. You may also have to tune your hot end temp as well if youre not using hardened steel.

- Super tiny prints like screws or bolts or very small printable areas just will not work with this profile. You have been warned. The updated profile should help with smaller models.

- I used IC3D Clear Transparent filament (labelled as Natural), you can pick it up on IC3D's website or at your local Micro Center store. Other filament brands may not work with the exact extrusion multiplier that I have set. Again, no complaining if youre not using the same filament or hardware. Different filament brands and different nozzles require different settings.

- Keep your chamber around 38C. Theres room for movement with this, but for the love of Bambu, DO NOT let your chamber get over 42C. The extruder motor gets insanely hot under normal conditions to the point it burns you if you touch it. 42C+ and hot extruder motor = melted filament inside the extruder body. Your extruder WILL CLOG if you dont follow this rule! Ask me how I know. Open your top glass or take it off, ams risers are great for this purpose. Leave the exhaust fan at 40% or turn it up, thats your choice. But leave it on 40% or up. And keep your front door closed to your printer. For other printers, a chamber may not be necessary, but there cant be a draft around your print.

- 260C on the hotend, anything above or below this temp have lower quality transparency. Ive been working on this profile for 2 months or so.

- 80C bed to ensure the layers melt together properly and to keep the print sealed to the bed during the whole printing process. This is necessary.

- DRY YOUR FILAMENT IN A FILAMENT DRYER AND KEEP IT DRY! I cant stress this enough. If your filament is cloudy, its one of two things. Either your filament is wet (you didnt dry it for long enough or its not in a dryer while youre printing), or you turned on the toolhead fan too high.

- DONT RUN THE TOOLHEAD FAN TOO HIGH. This will cause the filament to cool rapidly before the next layer goes on, making each layer cloudy. 0% for layer times passed 15 seconds, currently 20% for 5 second layer times.

- 0.1mm layer height, leave this alone for top to bottom transparency. If youre brave enough to drop it to .08mm layer height, experiment around with it. But just know that .08mm layer heigh clogged my extruder a couple times because the filament wasnt moving through the extruder fast enough which caused the heat from the extruder motor to melt the filament inside the extruder body. Im pretty sure I also had a nozzle clog at .08mm layer height as well. A butane torch and Allen head tool was able to get me out of that bind.

- 25-30mm/s. This speed is the optimal speed for perfect transparency.

- PEI smooth beds, or pey or any other smooth pe style beds should work fine for glass like bottoms, dont use glue on these beds for this profile. If youre using a textured bed and complain that you cant see through it, thats your fault. Youll see through the model but not through the textured bottom. If youre using an engineering plate or a cool plate, just dont. If you do, use glue. Youll thank me later. Again if you cant see through it and you used glue, thats on you. If you for some reason are using a glass bed in these printers, which im sure is very possible, dont complain about trying to remove the print. Yea the glass bed would be perfect for a glass bottom finish, but probably a good idea to use glue for a glass bed for easy part removal.

- 100% infill for the best results.

- NO BRIMS. these are hard enough to remove from the models as it is. With an 80C bed, brims arent necessary. Unless you have a model with the tiniest base ever, id leave brims off. Or you can use a raft which I have not set up for easy raft-to-object removal.

- ALIGNED RECTILINEAR for all layer patterns is the best way for the layers to mend together properly and for the best transparency! Normal rectilinear gives you a crosshatched pattern through every single layer and you will see it. The extrusion multiplier will fill in the gaps automatically to where you wont see any pattern lines through the object youre printing.

- DO NOT USE FILAMENT FLOW CALIBRATION WHEN STARTING THE PRINT! This overrides the extrusion value thats set.

- Supports are off by default, but if your printing something with a large overhang or bridge, turn it on. Classic supports for small bridges and up are recommended. I havent tried tree supports on this profile so thats on you if you use it.

- If you do see lines between each layer in the x and y axis, lightly step your extrusion multiplier up by .002 and do some test prints till you get it dialed in. Not every printer will work perfect because of how the extruder motors are wound up in the factory.

This is the result of under extrusion:

This is the result youre looking for:

You might have boogers on the walls of square prints, this is normal for the extrusion multiplier thats set. Just use edge cutters and clean it up. You WILL have lines in the top surface, this is normal for the extrusion multiplier thats set. But if you have a plastic annealing oven or a butane torch, turn on ironing with the settings that are set for ironing already, and let it anneal, this should further improve your glass like finish! Ironing WILL cause boogers to form on the edges since its ironing out the extra filament thats lifted up. Using a torch is hard to do for annealing purposes, the part WILL warp as it cools and if you leave the torch on it for too long, it will start to bubble and ruin the part. For my safety and your safety on the torch method, I AM NOT RESPONSIBLE FOR DAMAGES OR YOU BURNING YOUR HOUSE DOWN. Use safety gear, go in a well ventilated area and keep a fire extinguisher next to you during the torching process just in case. Thank you love you <3

This is what torching your top layer would look like at 5mm thick:

Fixed the issues that were underlined here, check out the new updated profile!

Comment & Rating (47)

License

You shall not share, sub-license, sell, rent, host, transfer, or distribute in any way the digital or 3D printed versions of this object, nor any other derivative work of this object in its digital or physical format (including - but not limited to - remixes of this object, and hosting on other digital platforms). The objects may not be used without permission in any way whatsoever in which you charge money, or collect fees.