PP3DP UP Plus and UP Plus 2 are usually terrible with printing PLA. Three major issues with these printers are

1. The throat of the hotend gets too hot as heat creep up the steel tube and the PLA starts to bulge there and gets impossible to reliably extrude

2. Extruder stepper motor gets hot during print, both from the fact that it's a puny motor doing a lot of work and because it's used partially as a cooler for the cold part of the hot end. This heats up the PLA print and does not allow it to solidify properly, overhangs are crap and bridges are almost impossible.

3. PLA requires cooling, the "solution" originally is that hotend cooling duct has a "door" that let some of the air go into to part. The "solution" does not work.

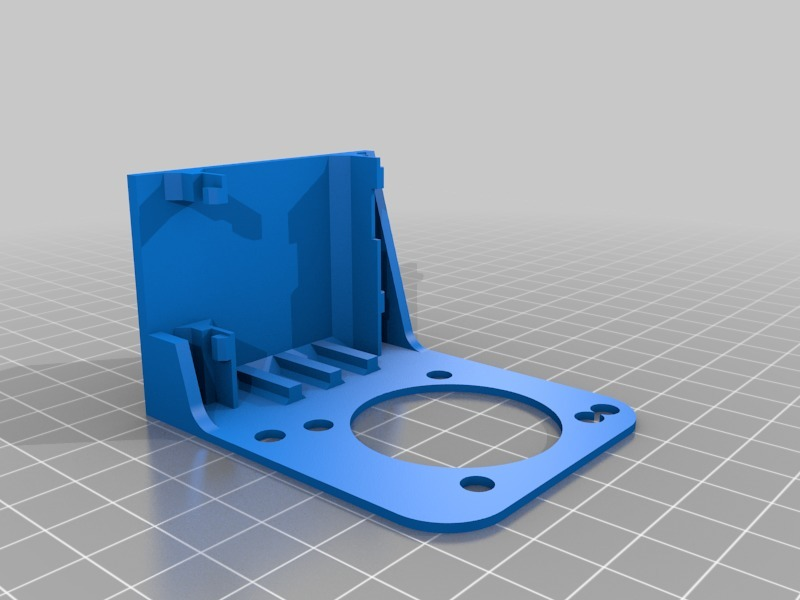

To solve these problems I started by redesigning the extruder cooling (https://www.thingiverse.com/thing:2509563). This solves both the issue of bulging inside the hotend and the problem with extruder getting too much heat from the hotend. This solves all the print issues with ABS, PETG, PC, Nylon.. but is not enough for PLA.

To tackle second and third problem this small project was created.

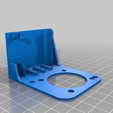

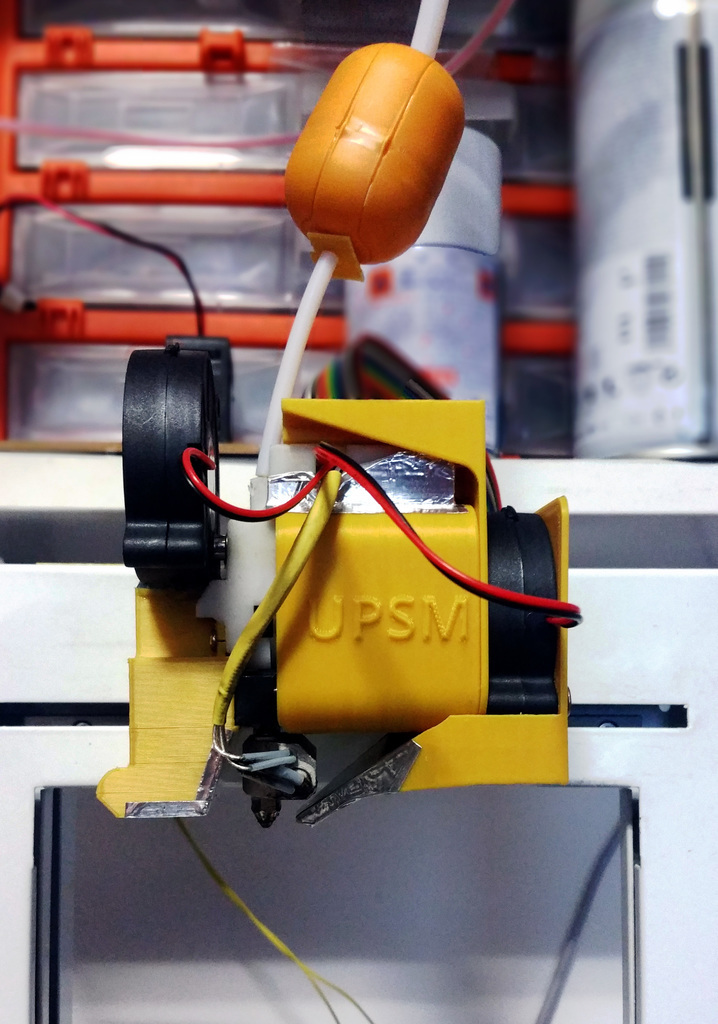

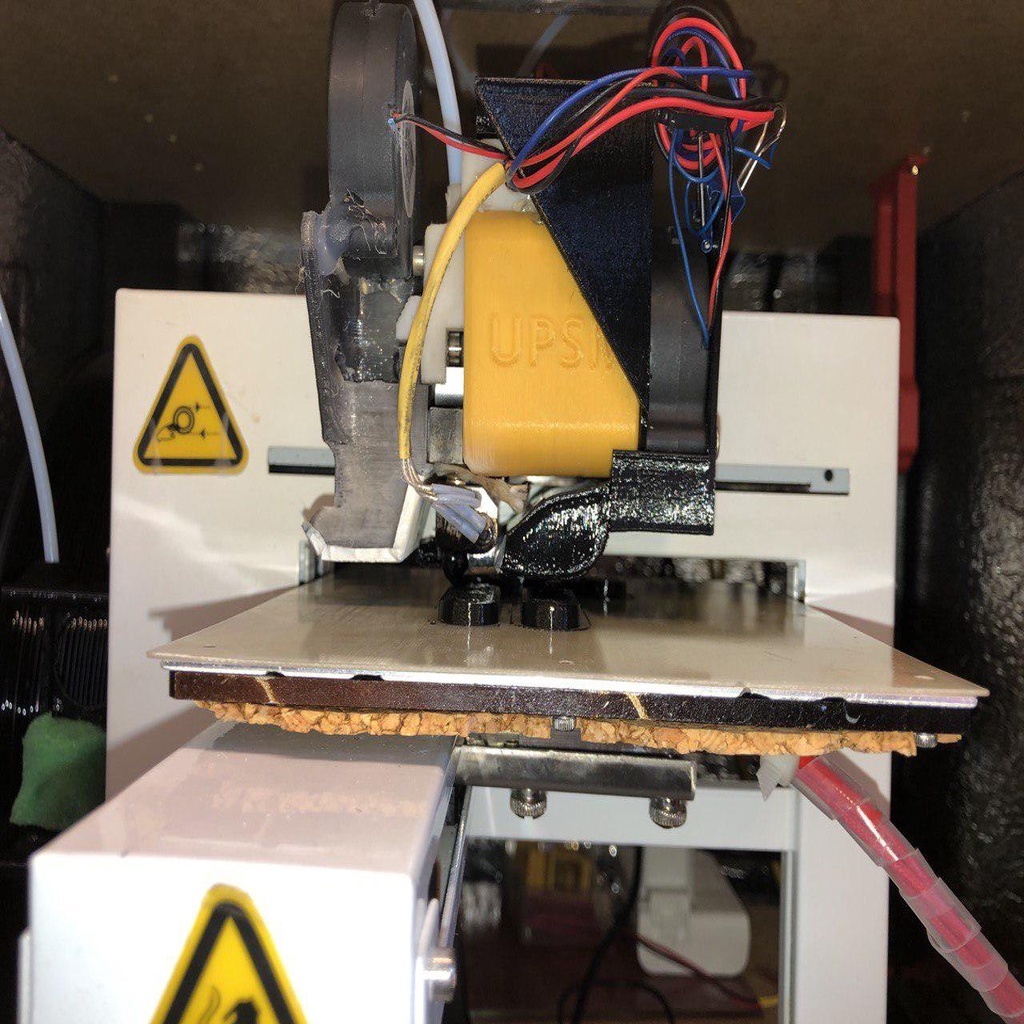

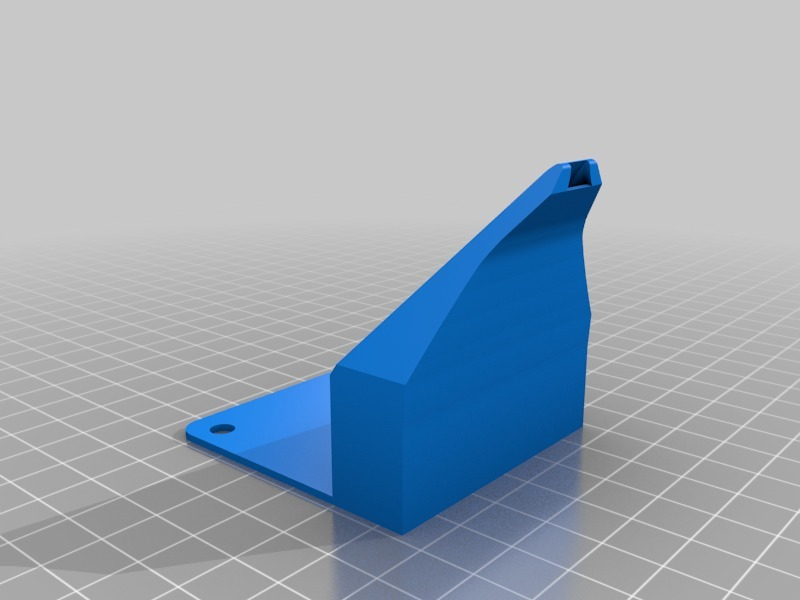

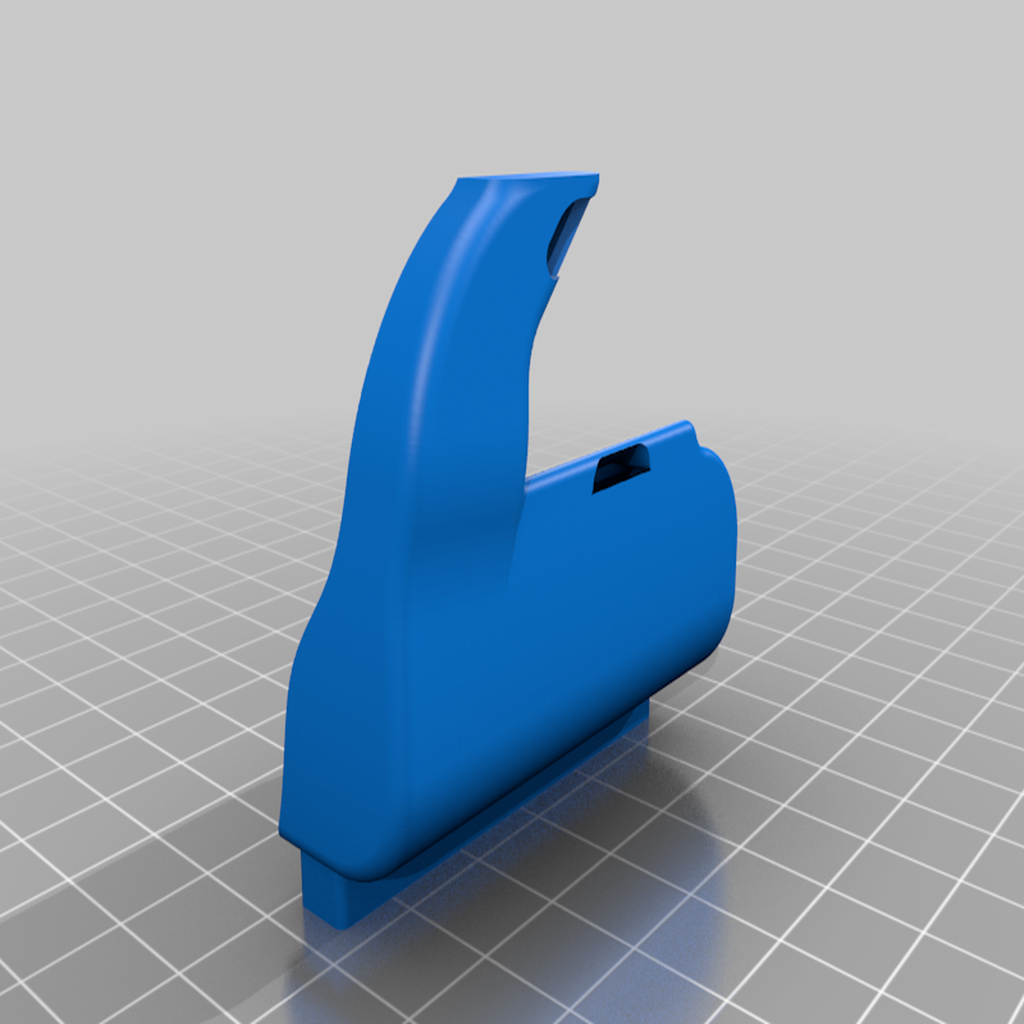

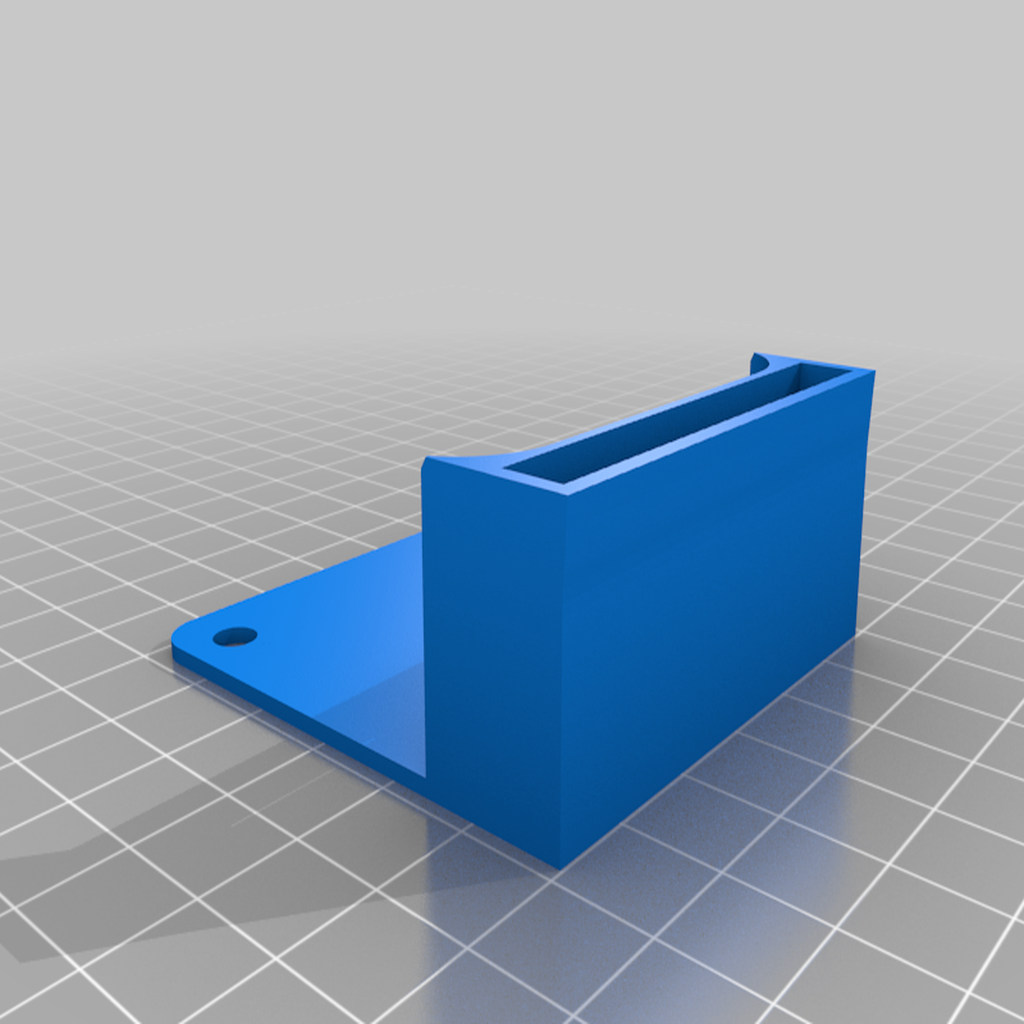

The fan duct goes over the stepper motor and allows for air to pass around the motor and exit back to cool the motor. Make sure you are extracting air and not pushing air in. The "cover" part will clip in to original top part on the UP Plus / UP Plus2 and will come behind the fun duct keeping it in place. As you can notice on both cover and duct there is 2 set of screw holes, 4 holes for the 40mm axial fan and 2 holes for the radial fan. If you do not need part cooling (ABS, PETG..) you mount 40mm axial fan here to extract air and you are golden.

If you do want to use part cooling fan (PLA requires it), I decided to recycle the air and push the air that we get from cooling the extruder motor into the part. This way the air is not "too cold" and will not stress neither the part nor the nozzle and it should (time will tell, so far so good) create PLA parts with less in-built stress. The part cooling duct houses a radial fan (no glue, hotsnot, silicone .. needed, just put it there) and screws trough the back of the cover into the duct.

I'm using custom firmware on the UP Plus2 so I'm controlling the fan trough there. On the top board you can see 3 3pin connectors (picture attached). The leftmost is 12V supply where your extruder cooler is connected. Middle (on the right side of the board the left connector) is also 12V supply and you can connect your fan here. If you are using only motor cooling (no part cooling) this is where you want to connect your fan. The third, rightmost connector is PWM-able. Originally this is where "light strip" is connected on some of these printers. If you have CPU upgrade with NXP chip to run smoothieware (I do) this is on port 1.18. If you are using original UP Studio software then probably check if you can change "light intensity" from software to change fan speed or just connect part cooling to a constant 12V, there's usually never too much cooling for PLA so should work ok :D

smoothieware config:

switch.fan.enable true

switch.fan.input_on_command M106

switch.fan.input_off_command M107

switch.fan.output_pin 1.18

switch.fan.output_type hwpwm

switch.fan.max_pwm 100

switch.fan.ignore_on_halt true

switch.fan.startup_state true

switch.fan.startup_value 0

switch.sw1.fail_safe_set_to 100

UPDATE 20191125:

* COVER V2 - make the cover tad more rigid, required if you are printing in material that's not stiff enough (e.g. PETG can be too elastic for V1)

* part_cooling_duct-main V2.stl and part_cooling_duct-tip V2.stl replace the original part_cooling_duct.stl. This is now a 2 piece part (they just snap together) so you can easier change the tip and try out multiple different tips. the tip provided blows air from 2 sides now instead of only one V1 did allowing for much nicer prints but the tip requires support to print (turn on only support from bed)

/https://fbi.cults3d.com/uploaders/31399568/illustration-file/12942f37-d9f7-4774-9671-d694dc2c7a74/20170912_041607.jpg)