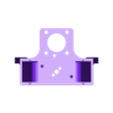

MGN12H G5+Mosquito/Mellow tool carriage with part cooling ducts

** FINALLY TESTED AND WORKING - 24h print done, no issues **

** Version with Precision Piezo holder available too: https://www.thingiverse.com/thing:4189461 **

(btw, no clue why is thingiverse not rendering STL's, they are all ok and available in thing files section - if anyone have a clue why are stl's not being shows pls lemme know in comments, tried to remove all files and add again and same thing)

This tool carriage is to be mounted to MGN12H linear rail (or any other similar linear rail that has 20x20mm holes for mounting). The tool carriage expects linear rail to be mounted on top of the X brace (so not in front of it).

The hotend mount holes are for Mosquito by Slice Engineering or Mellow (Mosquito clone, total POS, don't use it, it's really bad, get yourself original it's not much more expensive) hotend.

The integrated fan ducts are designed for two 50x15 blowers for maximum performance.

Extruder mount is for Flex3Drive G5 (latest and greatest) but if you want to go bowden just re-drill the filament hole on the holder and screw in the bowden tube holder and you are golden.

"blower screw holder.stl" is not required but you can print and mount it so your blowers are better secured. I myself like to glue blowers with glue-gun to the ducts.

belt clip - I use this to secure belt, just pull the belt trough a belt hole and clip on the belt-clip over the belt, I use this system for years never had a problem with belt loosening... this will not work with original belt as original is too short but if you are replacing belt it will be easy. If you are using original belt, cut (do not use fly cutters, use a saw or melt it) to cut a grove so you can pull your original belt loop like in the picture

Printing this prints .25mm layer, .5mm extrusion with .4mm nozzle in PETG on a rather shitty printer that is not very good doing bridges no problem, so you should be able to print this without any support easily. On V4 there's embedded support for the 2 nuts & washers for the hotend mounting. Just break off the embedded support and drill the hole trough 0.25mm shell using 2mm drill.

VERSIONS:

* V1.0 - holes (ears) for the belt added. You can cut the channel on the top of the hole so that you can slide the existing belt in if you don't want to make a loop around ears, but I suggest going for the loop, it's better

* V2.0 - thickened ears getting them closer to 2020 so that angle of the belt is better and added ziptie anchors in front for easier cable management (for heater and sensor wire). additionally, v2.0 STL is properly oriented for printing without supports. UPDATE: v2.0 seems to be working rather well, the only issue is that arm of G5 is too close to the left blower so I either need to rotate the G5 or redesign the arm on it.

* V3.0 - widened the whole holder for ~6mm so that there's room for the G5 arm (was hitting the blower) and also added a 3 new holes for the G5 so it can be rotated 90 degrees so that arm comes to the front (instead to the left) making it easier to open to replace filament

* V4.0 - thickened the plate, removed inserts added place for nuts & washers, now is solid as it can be, nothing falling out, shaking off... it works as expected

SOUND:

I'm testing with some PRC blowers "magic dragon BFB0512HH 12V 0.32A 5015 centrifugal turbo fan" that are not too powerful and in rather noisy environment but here are some numbers (average values, measured 3cm from the device):

- Ambient noise: 48dBA

- blowers powered with 9V in the fan-duct: 55dBA

- blowers powered with 12V in the fan-duct: 60dBA

- blowers removed from the fan-duct, freely floating 9V: 60dBA

- blowers removed from the fan-duct, freely floating 12V: 63dBA

I'm not sure how they are quieter with the duct but..

** EXTRUDER **

* G5 - tested Works with Flex3Drive G5

* BOWDEN - tested Originally I made this for myself to use with Flex3Drive G5 (awesome remote direct drive) but it can also be used with bowden extruder. There's the bowden adapter for the hotend, looks like a standard grove mount top that you can screw on the top of the mosquito/mellow and it has a hole on the other side where you feed in the bowden tube. In case you want to use this you just do not put the 2 nuts in the nut holes for the hotend, use longer M2.5 screws to screw in hotend to the grove bowden adapter trough the carriage and there you go you have a bowden adapter... use as any other bowden system.

* NEMA8 G5 can also work with NEMA8 motor as direct drive, so without the flex shaft thingy. I have never tried it nor I have the STL for the top cap of G5 to mount the NEMA8 on it so no clue if it would fit here or if part cooling blowers will be in the way.

* BMG There are bunch of BMG original's and clones that might fit here, but I don't own any so really have not tried.

IMPORTANT NOTES

* V3 tested in real printing conditions, the brass inserts fail and hotend drops out after few hours of printing (even sooner); the main issue is that "cold" side of the MELLOW NF CRAZY HOTEND (PRC clone of the slice engineering mosquito) gets hot and that heat transfers into brass inserts and they just pop out of the plastic so the whole hotend just slides from the filament pressure. It might work with original mosquito if it behaves as advertised but I doubt it.

* V4 tested in real printing conditions printing ABS, PETG, HIPS and PC (280C) and it held it's ground so it's now my main extruder on ENDER 5.

* Make sure you have the fan cooling the cold side of the extruder blowing non stop, maybe in some scenario it can work without fan but I doubt it.

* Aluminium tape - in my 10+ years experience with 3D printers and part design I figured that coating printed part with aluminium tape will reflect heat and even thermally incapable plastic like PLA can survive around hotend. I have pieces printed in PETG that are coated with aluminium tape on the side where they are exposed to 300-350C and they are still alive, not deformed.. the tape did not fall off .. (the one I use ATTM for e.g. is some "SCLEY 540", I think it's made in Poland) so I advice taping the inside of the carriage with aluminium tape. You can also go overboard with aluminium tape like on one of the images attached :)

* Mellow NF Crazy Hotend clone of the mosquito, while looks very similar is a total POS :( ... don't waste your time on it, it's not cheap and it does not work, especially if you want to print low temp materials like PLA .. just get the original, it's worth it.

/https://fbi.cults3d.com/uploaders/31399568/illustration-file/31ab49d2-9f1f-4f49-8f80-2c40d446f7d7/ASSEMBLY.jpg)