3D model description

A320 FCU PUSH/PULL Encoder V2.0 - mpantel6@outlook.com

Design by Michael Pantelis

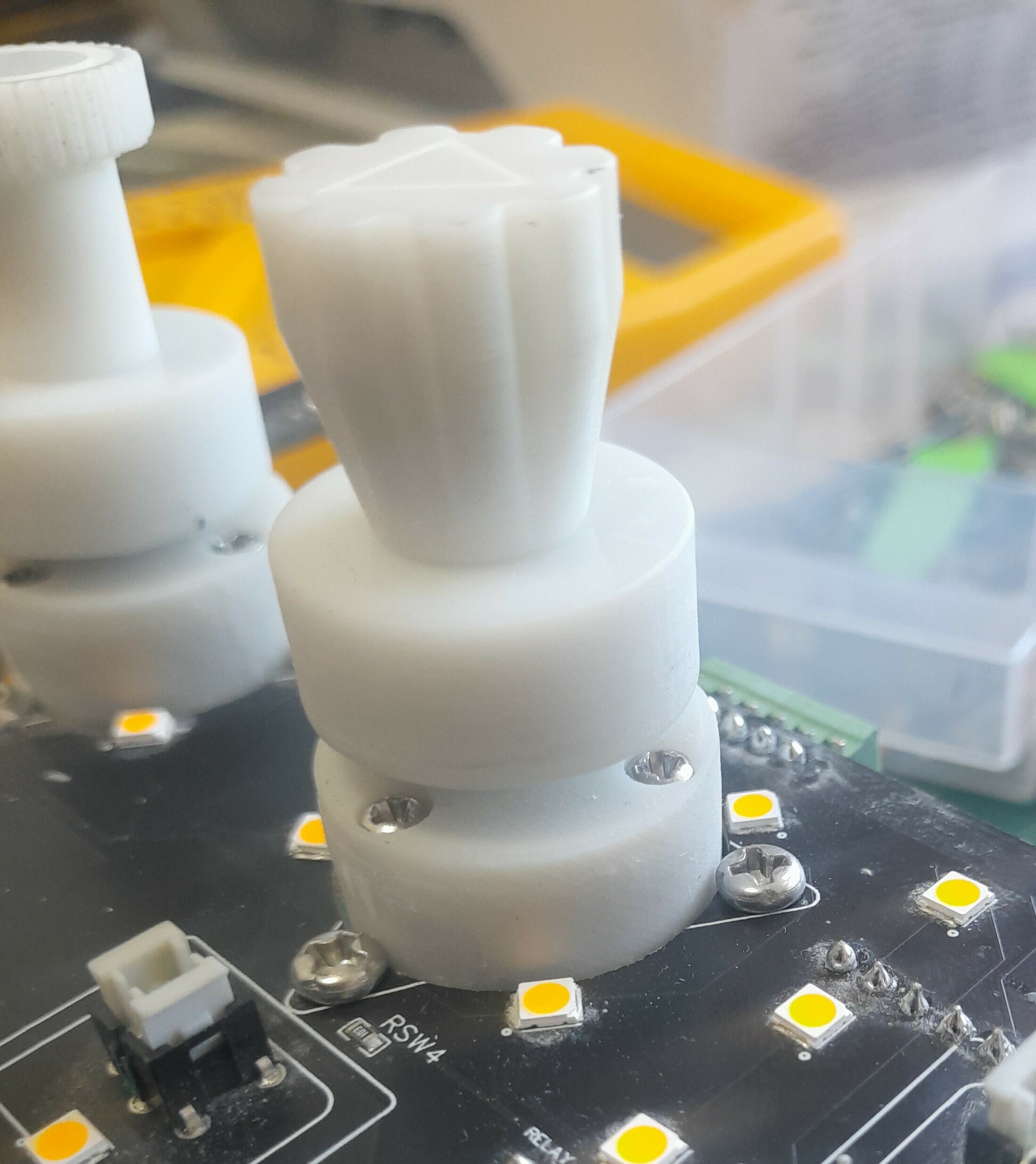

NOTE. FCU knobs STL files are not included. Knobs are only in the picture as an example. I'm still working on them. I will upload the knobs designs in a separated file soon.

About the Push/Pull encoder system.

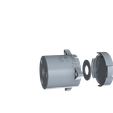

I have design and build a push/pull encoder system mainly for a320 FCU. However you can use it on any other project or home cockpit panel as well. I think it’s the smallest push pull encoder system around, with total length if 39mm long (encoder length including) and 23mm diameter. That means , your FCU back light doesn’t get disturbed on it’s way to the front panel by the encoder system.

It’s a very forward project and I believe an easy one to make. If you have any difficulties feel free to drop me a message in the email address which is on the top of this page. The file for FCU knobs is not included. I only have them in one of the pictures as an example.

The file is including, pictures, three STL files , two Gerber files and BOM lists for both encoder pcb and Pull switch pcb, so you can order and print the Pcbs for yourself. I use JLCPCB for manufacturing mine.

However , I can provide all the pcbs you need (8 in total), for 4 Push/pull encoders sets , for £30 in total.(Electronics components aren’t including . Shipping cost and taxes aren’t including too).

For better results I recommend all the parts to be printed by SLA printer. However you can still print them by using FDM 3d printer.

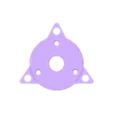

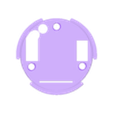

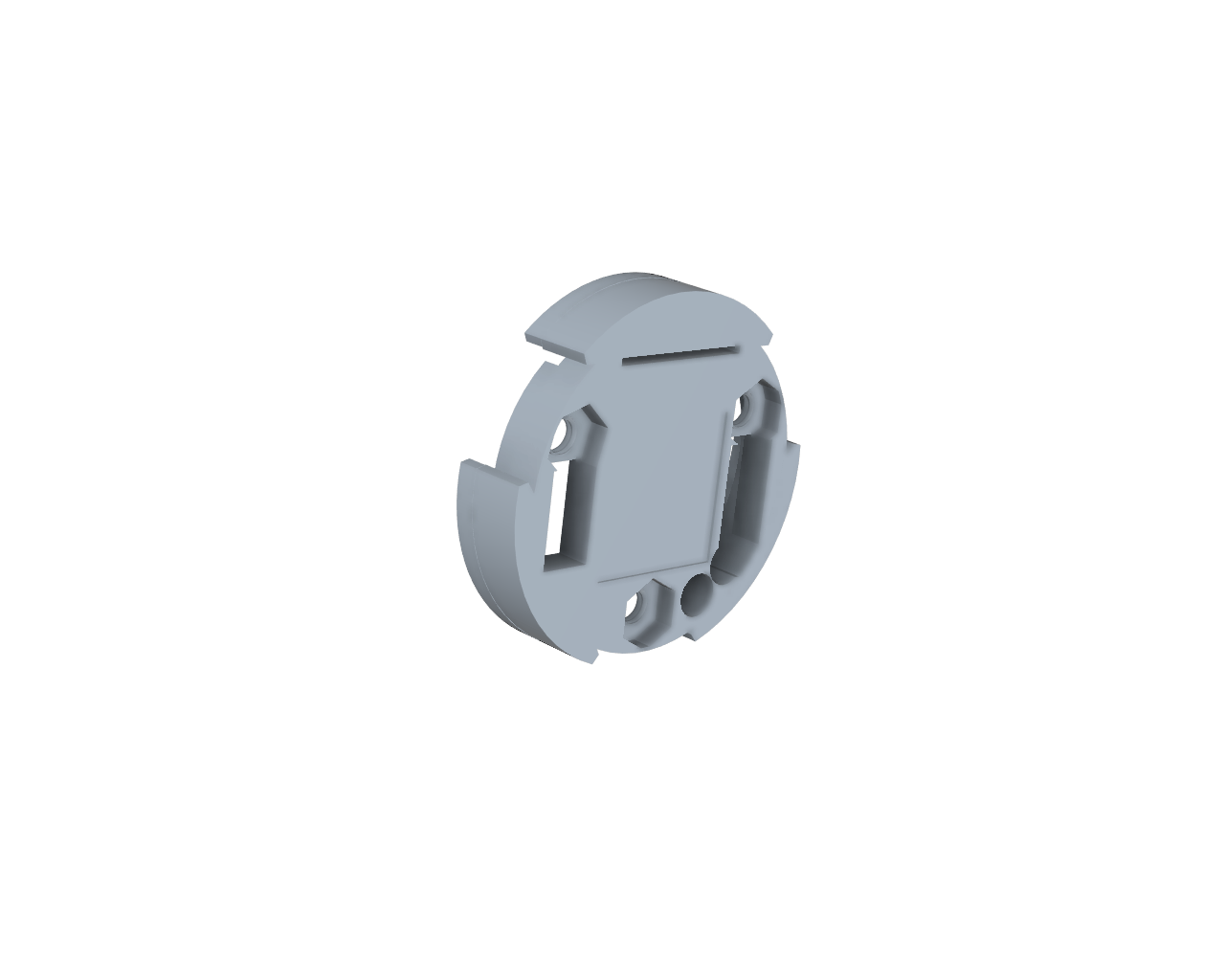

There are three different parts you have to print .

The main body, the rear cover panel and a washer/divider. The purpose of washer/divider is to work as a spacer between tactile switches PCB and the metallic surface of the encoder and it has to go through the encoder shaft and all the way down to encoder’s body thread.

3D printing settings

Main body Dimensions with the back panel: 27mm

Total length with the encoder system fitted: 39mm

Main body Diameter : 23mm

Back panel Diameter : 25mm

Ideal cut out hole diameter: 24mm

FDM printing

Ultimaker Cura 5.6.0 version settings for PLA using Geeetech A10 FDM printer.

You better print the main body with the front face on the build plate and the rear panel with it’s back on the build plate.

Profile: Extra fine 0.06 mm

Wall thickness : 0.5mm

Infill Density : 20.0

Infill Pattern : Zig Zag

Printing temperature : 205

Build Plate temperature : 55

Enable Retraction : Yes

Support : Touching Built plate

SLA printing

SLA printer Anycubic Photon Mono X settings for Anycubic White Basic resin. 405nm

Slicer: Photon Workshop v2.1.29.RC12

Slice Parameter

Printing with supports

Layer Thickness 0.050mm

Normal Exposure Time: 1.90 s

Off time: 0.50 s

Bottom Exposure Time: 30.00 s

Bottom Layers: 4

Anti-alias: 1

Z Lift Distance: 8mm

Z Lift Speed : 2.00 mm/s

Z Retract Speed: 3.00 mm/s

Components you need to buy.

3pcs 3mm female to female spacers

3pcs 3mm male to female spacers

3pcs M3 x 5mm Philips head screws

3pcs M2 x 25mm Philips head screws

3pcs M2 hexagon nuts

2pcs 6x6x7mm Tactile momentary switches

6pcs 1mm wire 80mm long. Or you can get 0.5m long one and cut it in 6 different wires with 80mm length each wire.

1pcs Encoder BOURNS PEC11R-4225F-S0024

/https://fbi.cults3d.com/uploaders/25397859/illustration-file/3b577e6d-6921-4c7b-bcfd-ab52221bf578/20240115_102421.jpg)