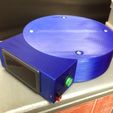

This is a magnetic stir plate based on a 120mm fan, powered by 12 volts. I wanted something larger and more stable than the 80mm units. It uses a PWM speed controller from ebay, either with or without an LCD. At high speed it will throw the magnet, but that's much faster than the speed needed for a vortex to reach the bottom of the 2L vessel. With the 1.5" stir bar, the speed needed to keep a good vortex is well below 50%. It should work fine for larger vessels, given the rather large stir bar. I have only tested it with a 2000ml flask. So far it hasn't thrown the stir bar, unless I really crank the speed far beyond what's needed.

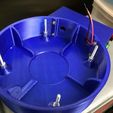

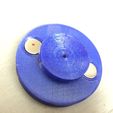

The magnets are N52 1/2" X 3/4". Go big or go home!

http://www.ebay.com/itm/321817266647?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

The magnets are quite strong. Handle them carefully! They will shatter if they slam together. The poles are on the flat ends. Alternate the poles when you press them into the MagnetMount. One side of the magnet will have a red dot. Make sure the one has the dot facing up and the other has the dot facing down.

1.5" stir bar

http://www.ebay.com/itm/181806493210?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

120mm fan w/HBD bearings

http://amzn.to/2kkzL8R

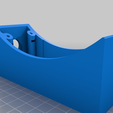

PWM speed controller (print the NoLCDSideCar.stl)

http://www.ebay.com/itm/351460554697?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

PWM speed controller with LCD (print the LCDSideCar). Not sure why I used this over the regular PWM controller, other than I like things that light up and change when I turn a knob. If you use this controller, you will have to break the tabs off the side of the LCD module. It should be a tight fit, but a little glue might be needed.

http://www.ebay.com/itm/112061036280?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

The side cars are bolted on with 1" #4 screws. They have cutouts for nuts, but the screws are tight enough where they probably aren't needed.

The 120mm fan is bolted to the base using 4 2" #8-32 machine screws. The screws are attached to the base first using 2 nuts for each screw. It needs the spacing from the 2 nuts. Three nuts hold the magnets a bit too far from the base. Test fitting the fan with the mag mount attached, adding washers until the mag mount stops touching the base, than add another washer. I ended up using 2 washers. Add a nut or two to keep the fan in place. There should be enough room for 2 nuts at the end of the screw.

http://www.homedepot.com/p/Everbilt-8-32-x-2-in-Phillips-Flat-Head-Machine-Screws-4-Pack-28471/202706132

Both sidecars have slots for Anderson Powerpole connectors. I have a ton of these and have ready access to 12V power served up through a fused distribution block (ham radio). I used a 2mm screw to "pin" the connector inside the side car housing. Don't have to use these connectors of course. Make sure whatever you use is safe from vibration and is properly fused.

https://powerwerx.com/anderson-powerpole-connectors-15amp-bonded

The MagMountBase is super glued to the top of the fan. The fan hub is curved, with a matching curve in the printed base. This must be as well centered as possible. Use a slow drying glue to give you enough time to properly center it. The magnets are pressed into the MagnetMount, with alternating poles on the same side. The MagnetMount should slide onto the top of the MagMountBase. A little knife scraping may be necessary to fit them together without force. Either use a 3mm x 10mm screw to permanently keep them together or just use super glue. I created 2 parts in case I needed to alter the spacing of the magnets or change to different magnets without having to re-glue it to the fan. The 4 #8 screws actually support the entire stir plate, with the screw ends resting on the table. A non-skid mat will keep it from moving around, especially if the MagMountBase isn't well centered on the fan.

I modeled this in Fusion 360. The source files as well as IGES are included.

I printed it in PETG since that's what was in the printer. Infill was 30% with 3 solid layers.

/https://fbi.cults3d.com/uploaders/24563018/illustration-file/6f94dcb6-e7c9-4ce2-9ebf-a2f324efbc26/IMG_1357%5B1.JPG)