Long story short

Before all, I want to credit @Filboyt, @Elzariant and @Kenopy, for their creations

**[EDIT 09.2023]* Hi everyone, i tried to replace my heatbreak for a one that can handle more temperature, like 260°C, with the PTFE tubing that goes not all the way down to the melting zone, so the PTFE is safe from burning or melting : thoses temperatures are very high. Then after my upgrade, i tried to print PLA and it was a nightmare (heatcreep phenomenon)*

With all i'vd read on the internet, I decided to :

- Give more room to air to flow through the radiator

- Apply thermal paste/grease directly arround the heatbreak to conduct the heat .

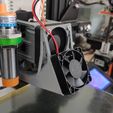

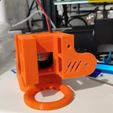

I'm proud to present you the version 5.1 with extra air flow :)

To test if the thing was ok to use with PLA i tried to use a thermocouple that was laying arround, i placed the thermocouple in front of radiator, then read a value of 30°C so thats OK for a filament to not start to melt where it souldn't . i'ill try to place the thermocouple behind the radiator but i think the value i read will be the same . => Did this after replacing stock cr10 fan with a 12V Noctua 40x10 with silicone sock on the heatblock, put the temp at 260°C then read value of 43°C max on idle position , ive read 35°C max using PLA (nozzle @210°C) wich is also okay to use allmetal heatbreack (or throat) with stock E3 .

I tried to print something with many retraction and it went perfectly fine, next upgrade is to replace loudy 24V stock fans with notcua 12v 40x10 Fan .

[EDIT 05.2023] As it is a personal challenge, can you do me a feedback of the problems you have encountered with the model ?

The challenge

I was looking for a radial fan-duct, for the ender 3 as my side radial fan was worn out : I do not wanted to buy a new fan from internet but instead use some fans I can found at dump or at work ( I work in IT so i can get some 40mm fans anytime, from dead computers or dead network switches)

The hard way

I also own a TEVO Tarantula and the first thing I printed in early 2017 was this very famously fantastico LPA Fanduct. I saw there was no types of things existing that can fit onto the Ender3 carriage so I designed one by myself using Fusion 360 . My result was inspired by the mini satsana thing and the LPA 5.5 Stock hotends by Elzariant . I used the Fusion 360 Ender3 f3d file that they have on their GitHub page here

The result

As always, I've learnt once again many many many tweaks and things from F360 on my 3 weeks design's warmup (+parametric design) . I was constantly opening the ender3.f3d and restarted from scratch, because i was not in the right spot each time I printed the tests things . I modeled up to 4 versions (the concepts in green and the developpements after) before the V5, and this V5 is finally usable :D

I added a small groove on the left side of the Satsana to have a little more space to turn the Allen key correctly, as I do not have an Allen key with the rounded head .

Also i've added an extra space to the metal plate carriage so the Fan ring can fit perfectly under and let the air flow through this.

Also the roller wont touch the 3D printed model there is 0.3 MM tolerance gap on the design. i can do a little bot more but not planned at the moment.

I did not proceeded to the air flow simulation because i felt the air going on the nozzle and the print result was OK