UPDATE

Uploaded V4 of the part cooling fan mount and duct. Better fit than V3 but probably just as effective.

UPDATE

Uploaded V3 of the part cooling fan mount and duct. I think it's better? Looks a little strange and kind of shaped like an octopus tenticles, so I've unofficially named it the "octopus cooler". There's also a link to a video showing it cooling my cup of coffee. It did cool the coffee down quite a bit.

UPDATE

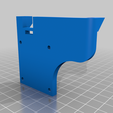

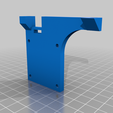

V2 of X Axis Mod Left and X Axis Mod Right have been uploaded. The Z endstop adjustment screw hole had to be revised slightly. Or the Z endstops could be moved up on the frame with a printed mod which I have not done.

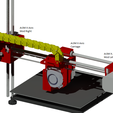

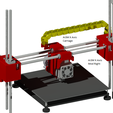

Here it is! The mod for the Anycubic i3 Mega to end all mods (in my opinion :-)). The parts here are my second version as I have already printed the the prototypes and they all work but I made some modifications/corrections/revisions to some of them. The Z endstop screw mounts are part of the additions to the first version so that part is untested as of yet but I think it should work fine. Also there is no mount for the X endstop sensor. My thought on that was to hot glue it to the left side in a very similar place as the original.

So I have taken both the rods on the X axis and rotated them 90° so that they are both parallel with the build plate. Then I suspended the carriage below the rods in order to accomodate the E3D Hemera direct drive hot end and extruder without loosing any build volume and keeping the nozzle in it's original location relative to center.

This is a pretty labor intensive project and takes a couple of hours or so to disassemble the printer and reassembly with the new printed parts.

Aside from the printed parts, all the rest are the original parts from the i3 Mega including the 2 X rods, 4 rod clamps, 2 Z rods and bearings, 2 Z drive bolts and brass mounts and the 2 X rod linear bearings. Some screws have to be swapped out for longer ones and some nuts have to be added. I will try to outline the procedure as best as I can, but for the most part it's all self explanatory. If you undertake this mod, more than likely you have experience with such mechanics.

There are a total of 8 parts including the chain mount. The chain used was my own which can be found here: https://www.thingiverse.com/thing:4674003. Only print the Chain Link part from this link. All the parts are titled coorsponding to where they will be placed based on a vantage point from the front of the printer. The color diagrams will show which part goes where.

Instructions are as follows:

1. Print all the parts.

Remove gantry frame from the printer. This video from Anycubic explains how, https://youtu.be/NRpfHr2njXs and screw the original metal frame mounts all the up and off the threaded rods.

Loosen X rod clamps and slide the rods out.

Remove the brass nuts, Z rod bearings and the X rod clamps from the metal mounts.

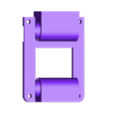

Assemble the Carriage parts. I used (4) 3mm heat inserted knurled nuts into the holes at the top of the 2 side plates (Ai3M X Axis CarriageLeft and Ai3M X Axis CarriageRight).

Insert the (2) X rod lenear bearings into the Ai3M X Carriage.

Screw the CarriageLeft and Carriage Right to the Carriage with 3mm screws (the large rectangular opening in the Carriage top is closest to the front.

Mount the E3D Hemera extruder to the underside of the Carriage assembly with (3) screws per side (see here for E3D's mounting recomendations: https://youtu.be/iOLz_6gP-nM, leave the (2) mount holes at the bottom back of the extruder motor open.

Use (2) heat inserted knurled nuts at the back of the Carriage top and mount the Carriage PCB holder into these knurled nuts.

Slide the X linear rods into the linear bearings now mounted to the Carriage assembly.

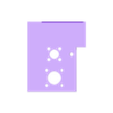

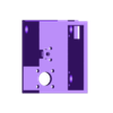

Install all the original parts into the newly printed X mount frames (labeled in the color diagram as "Ai3M X Axis Mod Left" and "Ai3M X Axis Mod Right"). Longer M3 screws will need to be used as well as nuts for the Z rod bearings. The holes in the printed parts may require a small amount of boring to widen the holes slightly depending on your how you sliced the parts. Mount the (4) X rod clamps to the inside of the X Axis Mod parts.

Insert the (2) X linear rods into the clamps but don't tighten the clamps.

Lower the now fully assembled X gantry onto the Z rods and thread them down a little ways.

Square both Z axis with the X gantry and tighten the X linear rod clamps.

Insert the belt around the gear and idler pully, run continuous through the top of the Carriage and attach the ends to the bar on the sides of the Carriage and clamp down with zip ties. Takes some finessing because of the tight fits.

Thread the Z endstop adjustable screw into the printed X Axis Mod parts.

Reinstall the gantry frame by reversing the procedure outlined in the video above.

Lower the X gantry and adjust the endstops accordingly.

Hot glue the X axis endstop to the left side printed part.

As I stated in the opening statement, this is a very labor intensive mod and should be under taken methodically and with lots of patience. So only attempt this mod if you are comfortable making such changes and taking all responsiblity for the changes to your own printer.

Please leave comments containing your thoughts or problems encountered and I will attempt to help as much as I can.

Again I have printed and installed all of these parts and the printer functions as anticipated, but again I took my time and methodicaly replaced and installed everything.

Also take a look at the video of the prototype parts in action.

/https://fbi.cults3d.com/uploaders/20190762/illustration-file/599d52cc-15f6-40be-b8a9-bbef8c4ed113/Ai3M_X_Axis_Mod_LeftV2.png)