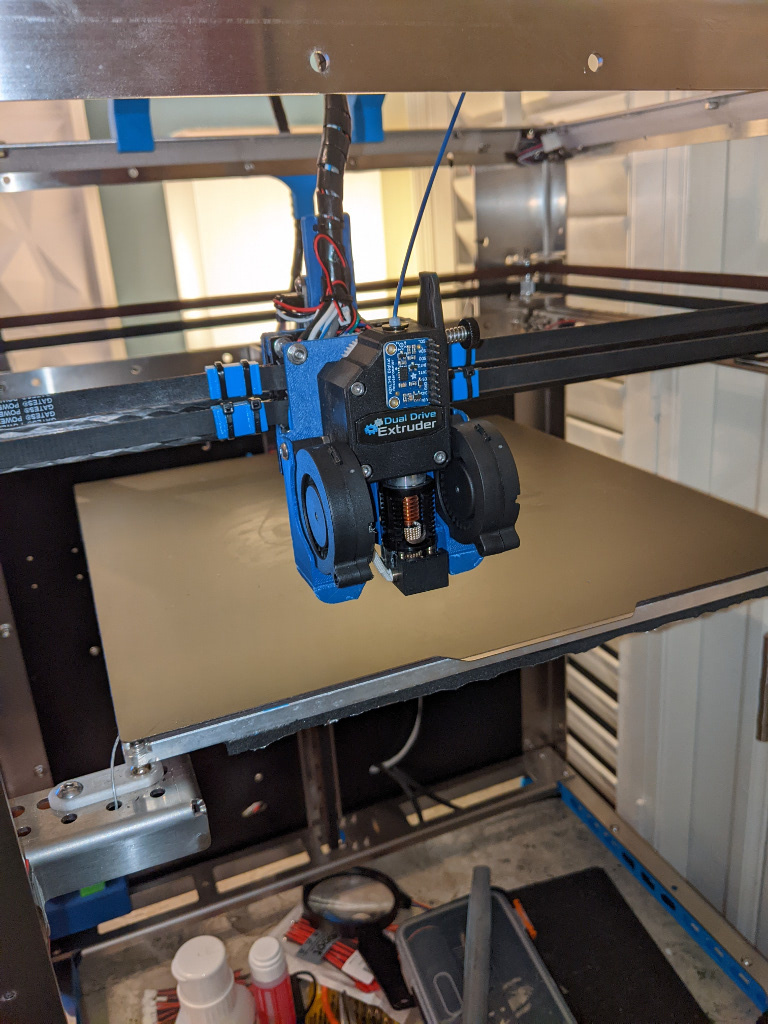

This is a replacement SecKit SK-Tank mount for a BMG and CF gantry, with dual 5015 radial/blower fans for part cooling, and a ducted axial 30mm (3010, 3015, or 3020) fan for hotend cooling. The same mount supports the Dragon HF, E3D V6, and E3D Volcano using different friction-fit air ducts for part cooling.

EDIT 2022-02-25: Added support for BLTouch. There are two mounts - one for Volcano, and one for V6 and Dragon HF. I recommend printing these in the default orientation for strength. The Volcano one can be printed without supports, but the V6/Dragon one will probably need supports (build plate only).

EDIT 2022-04-07: Added a mount for the Euclid Z probe toolboard. I recommend putting the dock in the back right corner of the Tank, with this mount going on the +X side of the back of the extruder plate. That way homing X and Y will go away from the dock, minimizing any chance of collision. My dock design is posted separately (https://www.thingiverse.com/thing:5345188) as it is not dependent on this toolboard mount or even this extruder setup.

In future, I plan to add support for the stock aluminum gantry... the hole pattern is a bit different so this one only works on the CF gantry.

Assembly instructions:

* Print the parts. The default orientation should be OK, but adjust as needed.

* Tap the hotend fan holes in the back of the extruder plate for M3, or your preference. The holes as designed are intentionally a bit small for M3, so they tap easily. If you don't plan to tap them you may want to drill them with a 3mm bit to accept an M3 screw.

* Install the hotend fan.

* If using an inductive probe, install the inductive probe (height is not important yet, just put it about halfway) into the L-shaped inductive probe mount, with the L pointing up.

* If using a BLTouch, install the BLTouch into the appropriate mount, with the wires facing away from the mount. The mounting point for the BLTouch is at the top of the mount, with the BLTouch hanging down facing the mount. The slot should allow a bit of vertical adjustment.

* Install the probe mount to the extruder plate using two short M3 screws.

* Remove the 4020 duct, BMG and hotend, if installed.

* Sandwich the extruder plate between the extruder stepper and the BMG, and start the three long M3 screws. Do not tighten fully just yet.

* (Dragon HF only) Rotate the hotend so that the heat block points towards the front. This is to prevent radiant heat from deforming the hotend fan duct.

* If necessary, reverse the heater and thermistor so that the wires will exit to the left.

* Tighten the three long M3 screws to firmly attach the BMG to the stepper motor and lock the hotend in place.

* Pass the heater and thermistor wires through the rounded pass-through hole in the extruder plate.

* Trim and/or file the inside of the fan duct attachment sockets, so that they are smooth and free of obstructions.

* Trim and/or file the fan ducts the same way. You may want to test fit them during the process to ensure they will go all the way in and fit snugly.

* Install the extruder assembly to the four existing M3 standoffs.

* On each of the 5015 fans:

* File down the top screw channel so there is room to accommodate a nut between the screw channel and the body of the BMG. The side that needs to be filed is different per fan; file one side on one fan, and the other side on the other fan.

* File down the little nub at the bottom of the +Y side of the fan, to allow it to seat fully.

* Test fit the 5015 fans. Make any necessary adjustments, then install the fans, placing a nut toward the inside, between the fan and the BMG. Run the wire for the left fan through the same opening as the other wires. Run the right one around the right side of the fan, then up along the stepper motor inside the standoffs.

* Insert the fan ducts until snug, then tighten them down at the top.

* Connect the wiring.

* Adjust the firmware configuration to reflect the new probe X and Y offsets. With the inductive probe the offsets are -22.2 mm for X, and +32.3 mm for Y. Accordingly you should also adjust your bed mesh and z tilt coordinates. I have pasted my current Klipper config below for reference.

* Calibrate the probe Z offset.

* Adjust fan speeds in your slicer.

* You're done!

My Klipper config:

# This file contains common pin mappings for the 6 stepper motor

# "FLYmaker Fly-CDYv2" board from creative3dprinter.com. To

# use this config, the firmware should be compiled for the STM32F407

# with a "32KiB bootloader".

# see hardware details on https://github.com/FLYmaker/Fly-CDYv2

# The "make flash" command does not work on the Fly-CDYv2. Instead,

# after running "make", copy the generated "out/klipper.bin" file to a

# file named "firmware.bin" on an SD card and then restart the Fly-CDYv2

# with that SD card.

# See docs/Config_Reference.md for a description of parameters.

# This file can be used as a basline printer.cfg for the SK-Tank

################################################################################################################################################################

# ATTENTION # You shall not use this file without checking and adopting the settings according to your actual built! (e.g. wiring, dimensions, extruder setup) #

################################################################################################################################################################

# Note: please check https://www.klipper3d.org/Config_Reference.html to get the full list of settings. Default settings and not set explicit in this cfg

########################################

# basic settings

########################################

[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32f407xx_220040001651383230343230-if00

[printer]

kinematics: corexy

max_velocity: 300

max_accel: 5000 ;set to 7000 for resonance test

max_z_velocity: 7

max_z_accel: 100

# Note: Extruder settings have to be set in on the extruder in the Steppers & Stepper

# Drivers section usig "max_extrude_only_velocity:" and "max_extrude_only_accel:" attributes

########################################

# Steppers & Stepper Drivers

########################################

# using TMC2208 configuration for TMC2225 steper drivers

# lower belt stepper left back

# usind X socket on Fly-CDYv2

[stepper_x]

step_pin: PE5

dir_pin: !PC0 # for standard SK-Tank wiring you have to change the direction by adding "!" so the new pin will be "!PC0"

enable_pin: !PC1

microsteps: 16

rotation_distance: 32 # Marlin/RRF reference: 200 steps / mm (rotation_distance = <full_steps_per_rotation> * <microsteps> / <steps_per_mm>)

full_steps_per_rotation: 400 # for a 0.9 stepper

endstop_pin: PC7

position_endstop: 0

position_min: -1

position_max: 350

homing_speed: 150

[tmc2208 stepper_x]

uart_pin: PC15

interpolate: True

run_current: 0.800

hold_current: 0.500

# upper belt stepper right back

# usind Y socket on Fly-CDYv2

[stepper_y]

step_pin: PE4

dir_pin: !PC13 # for standard SK-Tank wiring you have to change the direction by adding "!" so the new pin will be "!PC13"

enable_pin: !PC14

microsteps: 16

rotation_distance: 32 # Marlin/RRF reference: 200 steps / mm (rotation_distance = <full_steps_per_rotation> * <microsteps> / <steps_per_mm>)

full_steps_per_rotation: 400 # for a 0.9 stepper

endstop_pin: PD11

position_endstop: -3

position_min: -4

position_max: 324

homing_speed: 150

[tmc2208 stepper_y]

uart_pin: PA8

interpolate: True

run_current: 0.800

hold_current: 0.500

# Z stepper front left

# usind ZA socket on Fly-CDYv2 - ZB socket need to be jumpered when not used (connect 2B<>2A and 1A<>1B pin in socket)

[stepper_z]

step_pin: PE3

dir_pin: PB7

enable_pin: !PB8

microsteps: 16

rotation_distance: 32 # Marlin/RRF reference: 2000 steps / mm (rotation_distance = <full_steps_per_rotation> * <microsteps> / <steps_per_mm> * <gear_ratio>)

full_steps_per_rotation: 200 # for a 1.8 stepper

gear_ratio: 20:1 # to match z stepper 20:1 gearbox NEMA8

#endstop_pin: PB10 # use optical endstop for Z endstop

endstop_pin: probe:z_virtual_endstop # use BL-Touch or inductive probe for Z endstop

#position_endstop: 2.5 # disable when using BL-Touch or inductive probe for Z endstop

position_min: -3

position_max: 400

homing_retract_dist: 2 # added to lift the nozzle 2mm after homing vs. endstop

[tmc2208 stepper_z]

uart_pin: PB6

interpolate: True

run_current: 0.500

hold_current: 0.400

# Z1 stepper front right

# usind E1 socket on Fly-CDYv2

[stepper_z1]

step_pin: PE1

dir_pin: !PD3 # direction inverted since SK-Tank setup is using flipped stepper orientation for Z1

enable_pin: !PD4

microsteps: 16

rotation_distance: 32 # Marlin/RRF reference: 2000 steps / mm (rotation_distance = <full_steps_per_rotation> * <microsteps> / <steps_per_mm> * <gear_ratio>)

full_steps_per_rotation: 200 # for a 1.8 stepper

gear_ratio: 20:1 # to match z stepper 20:1 gearbox NEMA8

[tmc2208 stepper_z1]

uart_pin: PD1

interpolate: True

run_current: 0.500

hold_current: 0.400

# Z2 stepper back center

# usind E2 socket on Fly-CDYv2

[stepper_z2]

step_pin: PE0

dir_pin: PA15

enable_pin: !PD0

microsteps: 16

rotation_distance: 32 # Marlin/RRF reference: 2000 steps / mm (rotation_distance = <full_steps_per_rotation> * <microsteps> / <steps_per_mm> * <gear_ratio>)

full_steps_per_rotation: 200 # for a 1.8 stepper

gear_ratio: 20:1 # to match z stepper 20:1 gearbox NEMA8

[tmc2208 stepper_z2]

uart_pin: PE9

interpolate: True

run_current: 0.500

hold_current: 0.400

# extruder stepper

# usind E0 socket on Fly-CDYv2

[extruder]

step_pin: PE2

dir_pin: !PD6

enable_pin: !PD7

microsteps: 16 # values set for Biqu H2

#rotation_distance: 3.45 # Biqu H2. Marlin/RRF reference: 1900 steps / mm (rotation_distance = <full_steps_per_rotation> * <microsteps> / <steps_per_mm> * <gear_ratio>) # values set for Flex3Drive G5 Flex Extruder

rotation_distance: 7.71 # Triangle Lab BMG clone

full_steps_per_rotation: 200 # for a 1.8 stepper

#gear_ratio: 19:16 # values set for Flex3Drive G5 Flex Extruder

nozzle_diameter: 0.400

filament_diameter: 1.750

#max_extrude_only_velocity: 40 # values set for Flex3Drive G5 Flex Extruder

max_extrude_only_distance: 100.0

#max_extrude_only_accel: 60 # values set for Flex3Drive G5 Flex Extruder

#pressure_advance: 0.05

heater_pin: PD12 # T0

sensor_pin: PA3 # T0 Temp

# Thermistor - Biqu H2

#sensor_type: NTC 100K beta 3950

#control: pid

#pid_Kp: 13.385 # to be adjusted by running PID_CALIBRATE HEATER=extruder TARGET=205

#pid_Ki: 0.386 # to be adjusted by running PID_CALIBRATE HEATER=extruder TARGET=205

#pid_Kd: 115.950 # to be adjusted by running PID_CALIBRATE HEATER=extruder TARGET=205

#Thermistor

- Triangle Lab Dragon HF

sensor_type: NTC 100K beta 3950 # basic Thermistor, type to be verified by Ernest

control: pid # changed to "watermark" and comment/delet the PID seetings below if you have issues with the SSR (like some SSR dont like PID control)

pid_Kp: 23.242 # to be adjusted by running PID_CALIBRATE HEATER=extruder TARGET=220

pid_Ki: 1.476 # to be adjusted by running PID_CALIBRATE HEATER=extruder TARGET=220

pid_Kd: 91.516 # to be adjusted by running PID_CALIBRATE HEATER=extruder TARGET=220

min_extrude_temp: 170

min_temp: 0

max_temp: 260

[tmc2208 extruder]

uart_pin: PD5

interpolate: True

run_current: 0.800

hold_current: 0.300

########################################

# BED HEATERS & FANS

########################################

[heater_bed]

heater_pin: PB0 # BED

sensor_pin: PB1 # B-TEMP

sensor_type: NTC 100K beta 3950 # basic Thermistor, type to be verified by Ernest

control: pid # changed to "watermark" and comment/delet the PID seetings below if you have issues with the SSR (like some SSR dont like PID control)

pid_Kp: 53.190 # to be adjusted by running PID_CALIBRATE HEATER=heater_bed TARGET=60

pid_Ki: 2.955 # to be adjusted by running PID_CALIBRATE HEATER=heater_bed TARGET=60

pid_Kd: 239.354 # to be adjusted by running PID_CALIBRATE HEATER=heater_bed TARGET=60

min_temp: 0

max_temp: 100

[fan]

pin: PA0 # FAN0 used as print cooling fan

[heater_fan FAN1]

pin: PA2 # FAN1 used as hotend cooling fan

heater: extruder

heater_temp: 50.0

#[controller_fan FAN2]

# this will allow you to connect to driver cooling fan to FAN2 instead of VCC (permanent power) so its only cooling if the stepper drivers are active

#pin: PA2 # FAN2 used as controller cooling fan

########################################

# Inductive sensor

########################################

[probe]

pin: PB10

#x_offset: -22.0 # BMG/Dragon stock

#y_offset: 16.0 # BMG/Dragon stock

x_offset: -22.2 # BMG/Dragon dual 5015s

y_offset: 32.3 # BMG/Dragon dual 5015s

#x_offset: -27.4 # BMG/Dragon Berd-Air

#y_offset: 14.9 # BMG/Dragon Berd-Air

z_offset: 1.05

speed: 7.5 # Speed (in mm/s) of the Z axis when probing. The default is 5mm/s.

samples: 1

########################################

# BL-Touch

########################################

#[bltouch]

#sensor_pin: ^PC2

#control_pin: PE6

#pin_move_time: 0.4

#stow_on_each_sample: True

#probe_with_touch_mode: True #Needed

for BLTouch V3.0 / V3.1

#x_offset: -26.0

#y_offset: 0.0

#z_offset: 2.65

#speed: 5

#samples: 2

#sample_retract_dist: 2

#samples_result: average

[safe_z_home]

home_xy_position: 175,175 # Change coordinates to the center of your print bed

speed: 150

z_hop: 10 # Move up 10mm

z_hop_speed: 7.5

[bed_mesh]

speed: 150

horizontal_move_z: 3

mesh_min: 35,51 #Probe

coordinates

mesh_max: 310,341 #Probe

coordinates

probe_count: 7,7

algorithm: bicubic

bicubic_tension: 0.2

move_check_distance: 5

split_delta_z: .025

fade_start: 1

fade_end: 10

#fade_target: 0

[z_tilt]

#Positions

of the bed mounts, in nozzle coordinates. Shouldn't need to change these once set up.

z_positions:

6, 6

344, 6

175, 325

#Positions

to measure, in nozzle coordinates - i.e. make sure the probe is above the bed when the nozzle is at these positions

points:

31, 0

350, 0

203, 278

speed: 100

horizontal_move_z: 10

retries: 2

retry_tolerance: 0.1

[force_move]

enable_force_move: True # Set to true to enable FORCE_MOVE and SET_KINEMATIC_POSITION

########################################

# Input Shaping

########################################

[mcu rpi]

serial: /tmp/klipper_host_mcu

[adxl345]

cs_pin: rpi:None

[resonance_tester]

accel_chip: adxl345

probe_points:

175,175,20 # an example

[input_shaper]

# Biqu H2

#shaper_freq_x: 74.0

#shaper_type_x: mzv

/https://fbi.cults3d.com/uploaders/25604171/illustration-file/2d76cf44-b3a8-43fd-891c-70c2c4e0d83c/Front_View_reduced.jpg)