3D model description

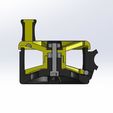

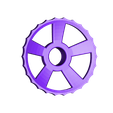

This is another Fly Reel I designed a few years ago. This one is Ultralight Design and was designed and paired this with a cheap Eagle Claw Featherlight 3/4 Line Weight Fly Rod I found on Amazon.

Let me start by saying I know very little about fly fishing and not a damn thing about fly reel design. Much like my other printed fly reel I made this just to see if I could.

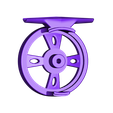

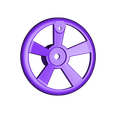

This is a simple Click and Pawl design reel - it uses a spring, ball, and dents designed into the spool to control the very "limited" drag. It was designed to use your hand against the outer spools rim if you need more drag.

Notice - If your looking at this think it would be a cheap way to get into fly fishing I highly recommend going another route. Shorter/lighter fly rods are harder to cast... get something better/larger or you will just get frustrated and quit.

Ok.... with all that out of the way on to the nuts and bolts....

Hardware Required

(1) 10-32 x 1" Socket Head Screw and Nut (See Notes Below)

(1) 4-40 x 1/2" Flat Head Screw

(1) Thrust Bearing (or washers See Notes Below)

(1) Spring & Ball

Notes

Nut-

The nut for the spool is embedded into the actual thumb knob during printing and requires a thin nut. (I used a 18-8 Stainless Steel Thin Nylon-Insert Locknut from Mcmaster Item# 90101A225) You could probably just use a nut and washer but seeing it's used to set the drag of the reel (so to speak) it might be hard to adjust in the field without a tool if you went that route.

If you can not find a thin nut I have included two different thumb nut files to choose from....

Ultralight_Fly_Reel_Thumb_Nut.STL uses a Thin Nylon-Insert Locknut with with these specs

Ultralight_Fly_Reel_Thumb_Nut_Full.STL uses a full sized Nylon-Insert Locknut with with these specs

Thrust Bearing

Unfortunately I made this so long ago I don't remember were I bought the thrust bearing from. (probably eBay) The thrust bearing setup measures .472" (12mm) Width x .176" (4.5mm) height. (you could probably substitute a few plain washers in place of the thrust bearing.)

Spring and Ball

The spring and ball for the clicker/drag can be a Pen Spring and a BB but they will rust over time. I used a .186" chrome ball (Honda Motorcycle Part# 96211-06000) and I also used a cut down stainless steel spring I found locally. Use a small hex wrench to press the spring and ball into the hole while pressing the spool down then just remove the hex wrench and the spool should fit into place holding the ball. It's a little tricky but not impossible. Hold the spool in place untill you tighten the thumb knob.

Misc.

The hole for the spool bolt was left small and tapped with a 10-32 tap. (You can probably just force the screw in but it might crack.) The Handle pin was also tapped for the 4-40 screw.

3D printing settings

Printing

Printing this reel is a little more difficult to print than my other fly reel because of all the curved surfaces. This was as much test for me in printing as it was reel design.

Everything was printed in the orientation shown in the STl previews. The spools halves will take a lot more support this way but I wanted the outer surfaces to look the best I could get them. The inner spool surfaces where sanded smoother to keep any excess wear from happening to the fly line.

If you have any questions or problems with the files or fitment of the parts just let me know and I will try to fix them.

Remember if to tip your waiters designers if you like the service.... thanks for looking

/https://fbi.cults3d.com/uploaders/12934067/illustration-file/11c4b075-2608-445a-b857-242968d5d47f/Capture%20d%E2%80%99e%CC%81cran%202017-08-07%20a%CC%80%2017.46.43.png)