Don't be scared by the long instructions. It's easy, I just want to be precise. If there are questions, please ask in the comments.

If you want detailed instructions with pictures, please see my instructable on http://www.instructables.com/id/The-Bicycle-Bubble-Machine/

Apart from printed parts, you will need:

+ a piece of wood to mount the machine on, which will then be put onto your luggage rack; I used 10cm x 70cm to have one bubble machine on each side (the wind wheel mount protruding a little over the edge of the wood); you should take less than 10cm width, however, as some bubbles that move down are less likely to pop then

+ small self-tapping screws (so your plastic doesn't break), optionally also small wood screws

+ sewing accessories: elastic ribbon (the stuff that makes your knickers hold, I used 8mm wide black), needle and thread, fixing pins

+ something to make the axles for the two wheels: I used 2mm welding wire (straight sticks); toothpicks will work, too, but they will break easily

+ small drills (like 2.5mm) to drill open the holes for the axis, as many 3D printers will not make the holes dimensionally correct; screwdriver and the like

Print one of every part, two of each clip (measure the diameter of the tubes your luggage rack is made of and tell me, if you need different clips). Print either two 3mm spacers or one 6mm. As for the slicer settings:

+ it is very likely that you'll need a raft to print at least the wind wheel; on my (probably badly calibrated) printer I also needed a raft to print the tank

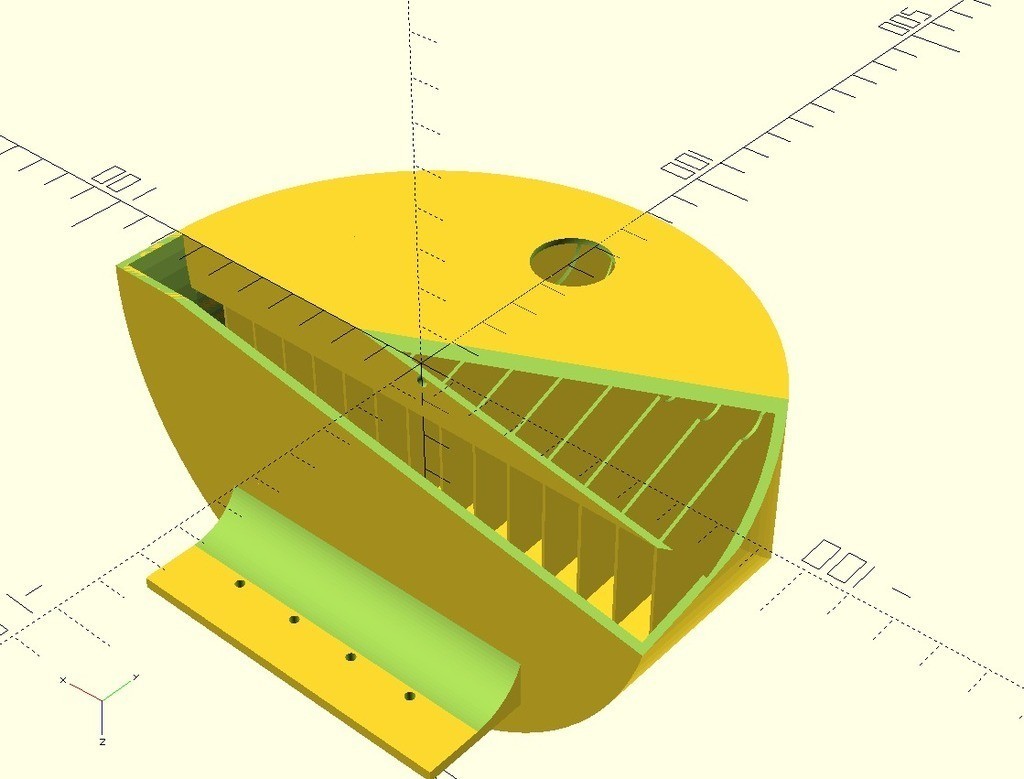

* the tank should be as solid as possible so it doesn't leak bubble fluid. My first tank with 20 % infill, two perimeters and two top/bottom layers leaked -- it didn't render it unusable, but it got soapy on the outside and if you left the tank full at evening, there wasn't much fluid left the next morning. I then did three perimeters and four top/bottom layers, which made it better. You might also consider a coating

* for the tank you should enable support from printbed only, not elsewhere! This is because, inside the tank, there are bulkhead walls to prevent sloshing effects, which act as support also, but having additional support inside the tank will make it store less fluid, keep fluid in dead places and will be a mess to remove; but you will need support for the mount, so enable from printbed

* the tank will need a lot of bridging (roughly 10mm) in the slanted that begins at a Z-height of about 40mm; give this good layer cooling

* while I use the clips in PLA right now, I will replace them by ABS ones, which will last longer

Remove supports; for the support from printbed that it generated inside the tank above the refilling hole you best take a needle-nose plier. Take care to remove as much support as possible from the part of the tank where the wheel will be mounted - it should move freely.

Screw the clips to the down side of the wood -- mark their positions using the luggage rack you'll use later and attach them so that you will later first clip on from the side the clips with the opening on the side, then push down the other side of the wood to clip in the others -- see the beginning of the video and you'll understand.

Mount the tank on the inside, i.e. nearer to the luggage rack, with the screws. Put one axis into the large pulley, fixing it with a self-tapping screw through the hole in the pulley base. There are holes to do this with "trapped nuts" and corresponding screws, but this really isn't necessary, simple self-tapping screws suffice. Use a 2 to 3mm drill to make the holes right if they're too small.

Put the 10mm spacer on the axis. Now push the axis through the first axis hole in the tank. Inside, put the axis through the 6mm spacer or two 3mm spacers, then the wind wheel (with the screw hole on the other side), then through the second hole of the tank. Now, also fix the bubble wheel on the axis with a screw. Check the axis turns easily and both bubble wheel and pulley are fixed, moving with the axis.

Mount the wind wheel on the wind wheel mount, putting the small pulley on the back side of the mount, with the pulley base towards the mount. Fix both the wind wheel and the pulley on the axis using self-tapping screws. Now, mount the wind wheel on your piece of wood, with two screws in the long hole on the mount. Don't screw them tight on just jet.

Prepare the belt: cut a piece approximately 48cm long and put it around the pulleys so that it loosely fits. Fix it temporarily with a fixing pin or similar. Now test: the belt should be very loose: it has to be just tight enough that the friction will move the other pulley if you turn one (fill fluid into the tank for this test, as it gives resistance), but it must not be so tight that it skews your axis so they don't turn anymore. An even slightly too tight belt will result in no or fewer bubbles. When you're sure you have a reasonable diameter, sew the ends together, remove the fixing pins and cut off any overlapping piece of ribbon.

If you keep having problems with belt tensioning (i.e. getting the right friction), you might try this interesting remix, which adds spikes to the pulleys: http://www.thingiverse.com/thing:976106

Put the belt over both pulleys. Adjust the wind wheel mount with the long hole so that belt tension is just perfect; then tighten the screws.

I placed the whole machine just on the luggage rack like you can see on the photos and the video. You can easily make this more secure with a couple of zip-ties. I plan on adding clips soon so it can easily be attached by clipping it on the luggage rack.

Now have fun! Use good bubble fluid, there are great differences in quality.

/https://fbi.cults3d.com/uploaders/13760929/illustration-file/8f66c138-0495-4fd9-afab-be804011c5da/bubble-machine-double_display_large.jpg)