I've had some pretty good results printing on a glass bed with no adhesives and thought I would share what works for me.

(Feedback and other advice welcome)

Setup

Print Surface: Printing on the smooth glass side of one of these.

Other Mods

In the interest of full disclosure all other mods are listed here. These mods have not improved print quality as the same results were achieved with the stock hot end.

Hot End: Micro Swiss

Firmware: Marlin 1.1.19

Stepper Isolators: Isolators installed for X and Y steppers only.

Preflight Checks

Clean

Clean the print surface thoroughly a glass bed will give your first layer a mirror like finish. The bad news is that all dirt and defects will be visible.

I've had prints pick up a fingerprint from the glass bed, the stuff is basically silly putty.

Once the bed has been properly cleaned a quick wipe down with some alcohol and a paper towel is usually all that is required. However, if you've been printing with an adhesive a good scrubbing with water and dish soap will remove everything.

Be sure to dry well and wipe with alcohol to remove any soap residue.

Preheat

Warm up the bed allowing enough time for both the glass and any surrounding metal to reach temperature. If you are unsure how long this takes on your printer, repeatedly level the bed during warm up until it stops "changing".

Preheat the nozzle to 80% of print temp.

Home and Level

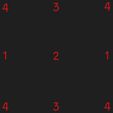

Give your bed a quick check before every print using a series of 9 points. This will help you visualize the surface of your bed.

Remember a bed is a flat sheet of metal secured at four points and will therefore behave a bit like a lever. When one corner is pulled down, two other point(s) will act as a pivot and the fourth point will want to go up slightly.

There is a detailed write up in the appendix section about leveling a bed "from scratch". It's a little bit of a read but I've had very good success using this method on several printers.

Executing the Print

Please see the appendix regarding recommended tweaks to printer profiles.

PLA

Material: 198-210; Bed: 52-55 (C).

If it's very cold out or I have had previous warping/adhesion issues I will "build" a temporary enclosure.

Since I haven't built a cabinet yet I use some cheap poster board to create an ad-hoc box around the printer. It isn't elegant but, the poster board stores nicely when not in use, holds plenty of heat, and doubles as a nice white backdrop when taking photos.

First Layer Won't Adhere

Caused by incorrect bed distance / level, dirt, or incorrect print temperature settings

Clean the bed; clean it again.

Check the bed height and level

Higher nozzle and/or bed temp

Less speed

Warping / Corners lifting

This is usually caused by heat differentials near the edge of the print.

Use a brim (they can really help here)

Use an enclosure

Higher bed temp

Print Pops Off Bed (serveral layers in)

Caused by excessive heat differentials, nozzle collisions or "gooey" filament pulling on the print during z moves.

Check bed level

Increase bed temp

Increase nozzle temp

Check z-hop and comb settings

ABS

Material 220-230 bed temp 75-90 (C).

Unless it's the middle of summer ABS will probably need an enclosure.

[To be expanded...]

Appendix

Level From Scratch

When starting with a bed that is wildly out of level identify and set the high point first.

Then, make your adjustments from the center outward, splitting the difference between the high and low points. Always adjust corners last.

Center high point(s)

Front to back

Left to right

Corners

After each adjustment step, return to the previous step(s), in order, and check clearance.

You may need to repeat this cycle several times but the amount of adjustment should decrease each cycle.

Please see the two examples below which will hopefully illustrate this concept.

Example 1 (center high): . My print bed has a slight "upside down U" shape. The center rail is the high point so I adjust in the order shown below.

Adjust for point 1 by turning all four knobs equally

Adjust for points 2 by turning both front or both rear knobs equally

Recheck point 1; split the difference between point 1 and points 2

Adjust for points 3 by turning both left or both right knobs equally

Recheck point 1 and points 2; split the difference between points 1,2,&3

Adjust corners by turning knobs individually

Recheck all points; split the difference between all points

Repeat as needed

Example 2 (center low): My friend's printer is the opposite, a regular U shape where the center rail is the lowest.

Adjust for points 1 by turning both left or both right knobs equally

Adjust for point 2 by turning all four knobs equally

Recheck points 1 and point 2; split the difference between point 1 and points 2

Adjust for points 3 by turning both front or both rear knobs equally

Recheck points 1,point 2, and points 3; split the difference between points 1,2,&3

Adjust corners by turning knobs individually

Recheck all points; split the difference between all points

Repeat as needed

Profile Tweaks

Here are some settings I have altered on my profile.

(links are not hot as they appear in my thumbnails where not desired

Calibrate: (watch this video) www.youtube.com/watch?v=3yIebnVjADM

Profiles: all have been set to "magic number" heights (watch this video) www.youtube.com/watch?v=WIkT8asT90A

Speed Print speed is 45mm/s

Retraction: 4.2mm @ 17mm/s

Z-hop: set to initial layer height

Z-hop height: height is set to initial layer height

Shell: typically 3 walls and at least .8 mm top and bottom.

Cheats

Hair Spray Tease

Occasionally all of this trickery still isn't enough. When that happens it's Aquanet to the rescue. Use the stuff in the purple can and spray a small amount on a paper towel. Allow to mostly dry and rub down the bed. You probably won't see much difference but you'll feel it.

If that doesn't work you can always fog the glass. (Don't do this while it's on the printer unless you like everything sticky.)

/https://fbi.cults3d.com/uploaders/14724948/illustration-file/c7de09f3-a355-418b-b053-3acb1826be5d/DSC_0047.jpg)