*

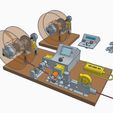

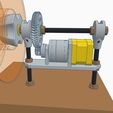

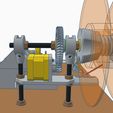

Once assembled my new FelFil extruder (https://cults3d.com/en/3d-model/tool/felfil-evo-extruder-case) I began to design a cheap and affordable spool winder; I had to design a cooler for extruded filament and a digital sensor for filament diameter.

It's modular, you can configure it at your needs. Only winder, winder and cooler with or without diameter sensor.

You can adjust manually the winder speed, but it can be managed directly from FelFil extruder (or others) speed.

With provided adapter the winder can support almost all spools around.

Among downloaded files you'll find STEP.ZIP with all .step required.

The new V7 version of firmware introduces MANUAL/ AUTO running mode and a filament diameter sensor that warns out if diameter is out of tolerance.

MAN/AUTO

If you choose LCD 1602 display you'll find a toggle switch to select AUTO or MAN.

If you choose TFT display you'll find two buttons on screen to select AUTO or MAN.

MAN mode lets you choose speed via the potentiometer while AUTO mode takes input PWM signal from extruder to automatically adjust winding speed relying on its extrusion speed.

RATIOS

Ratios are based on Felfil's range 0-9; with other extruders I'd advice to keep their output this range, otherwise you have to modify all parameters in section "// ratios:" (good luck!).

Furthermore, now the cooler fan speed is proportional to winding speed, utilizing D8 PWM output.

VARSPEED_V7.ZIP contains all necessary software and libraries; if someone get errors compiling due to an old version of LibCrystalI2C, is present an LIBCRYSTALI2C.ZIP with an updated one

In this V2 version you'll find:

- remixed filament diameter sensor (see Credits section)

- remixed cooler

- new spool clutch (yet to test)

Instructions

If you adopt LCD 1602:

- print case_cover_1602

- In VARSPEED_V7.INO change:

/////////////////////////////////////////////////////////////////////////////////////////////////////

#define LCD_TFT true // set to FALSE for LCD 1602

/////////////////////////////////////////////////////////////////////////////////////////////////////

and lead pins to LCD:

** LCD -> RAMPS**

SDA to I2C 20

SCL to I2C 21

V+ to I2C +

GND to I2C -

If you adopt TFT touchscreen:

- print case_cover_TFT

In order to use this display you've to place the Mega prototype between Mega and RAMPS; this way you can solder wirings to TFT without disturbing Mega board.

Warning If you adopt this solution you'll have to put 40mm fan outside case!

The pins you've to lead to tft are:

** TFT -> PROTOTYPE**

LCD_RST to A4

LCD_CS to A3

LCD_RS to A2

LCD_WR to A1

LCD_RD to A0

LCD_D2 to D2

LCD_D3 to D3

LCD_D4 to D4

LCD_D5 to D5

LCD_D6 to D6

LCD_D7 to D7

LCD_D0 to D8

LCD_D1 to D9

SD_SS to D10

SD_D1 to D11

SD_DO to D12

SD_SCK to D13

GND to GND

5V to 5V

3V3 to 3.3V

Firmware instructions

- to use LCD 1602 change

#define LCD_TFT true // set to FALSE for LCD 1602

to

#define LCD_TFT false // set to FALSE for LCD 1602

You can switch from AUTO to manual and viceversa touching for some seconds RED or GREEN button

adjustable variables:

////////////////////////////////////////////////////////////////////////////////////////////////////

#define LCD_TFT true // set to FALSE for LCD 1602

/////////////////////////////////////////////////////////////////////////////////////////////////////

/* DIAMETER SENSOR */

#define NUMTEMPS 14 //length of lookup table

#define smooth 50 //exponential smoothing factor, higher is smoother

// ADC input, diameter output

static float lut3[NUMTEMPS][2] = {

{117, 1.14},

{117, 1.14},

{122, 1.65},

{123, 1.75},

{124, 1.77},

{126, 1.82},

{129, 1.87},

{131, 1.90},

{134, 1.94},

{135, 1.95},

{137, 1.97},

{139, 2.00},

{234, 2.3},

{234, 2.3},

};

You can find your values simply opening Arduino IDE Serial Monitor at 57600

These are my results, for complete description, please refer to awesome Thomas Sanladerer (https://www.youmagine.com/designs/filament-diameter-sensor#information)'s filament diameter sensor (mine is scaled 50% of original).

/////////////////////////////////////////////////////////////////////////////////////////////////////

You can change below values at your needs

// tolerance checkout

if (temp < 2.4 & (temp > (diameter + tolerance)) || (temp > 0.83 & temp < (diameter - tolerance))) { //out tolerance

#if IS_TFT

OutDiameter(String(temp, 2), RED);

#endif

digitalWriteFast(led, HIGH); // alarm led ON

}

if (temp <= (diameter + tolerance) && temp >= (diameter - tolerance)) { // in tolerance

digitalWriteFast(led, LOW); // alarm led OFF

#if IS_TFT

OutDiameter(String(temp, 2), DARKGREEN);

#endif

}

if (temp > 1.95) { // too much out of tolerance

#if IS_TFT

stopped = OutStopDiam(LCD_TFT, is_manual, "THICK", millis());

#endif

}

if (temp < 1.65) { // too much out of tolerance

#if IS_TFT

stopped = OutStopDiam(LCD_TFT, is_manual, "THICK", millis());

#endif

}

/////////////////////////////////////////////////////////////////////////////////////////////////////

const float diameter = 1.75; // filament diameter

float tolerance = 0.1; // acceptable tolerance

const float Rol_diam = 72.2; // roller diameter adjust (roller diam 72.2mm, 1 mt = about 13.84 revolutions)

const float Rol_revPerMeter = 13.85; // counter adjust (roller diam 72.2mm, 1 mt = 13.846 revolutions)

float maxlenght = 330.0; // max lenght desired

float timeoutstop = 30000.0; // how many milliseconds of alarm before stop all

if in tolerance, filament diameter is shown in GREEN, otherwise in RED

if too much out of tolerance a timeout timer starts, see timeoutstop variable

if duration of out of tolerance is over timeoutstop variable value the system halts showing the reason (you can only reset)

once reached maxlenght the system halts showing SPOOL FULL (you can only reset)

BOM

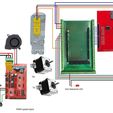

General

- n. 1 Arduino Mega2560

- n. 1 Ramps 1.4

- n. 2 stepper driver A4988

For TFT:

- n. 1 2.4" TFT LCD Touch Screen

- n. 1 Arduino Mega prototype board

For LCD 1602:

- n. 1 LCD 1602 I2C

- n. 1 Toggle switch SPDT

Common:

- n. 1 power supply 12VDC 5A

- n. 2 Nema 17 stepper motor

- n. 1 DVD stepper

- n. 1 potentiometer 100K linear

- n. 1 knob

- n. 1 40mm fan ball bearing

- n. 1 radial fan 50mm

- n. 2 Dilwe RC car 1/10 exhaust pipe coupler

- n. 1 shaft coupler 5/8mm- M8 nuts

- n. 2 608ZZ ball bearings

- n. 6 623ZZ ball bearing

- n. 1 panel jack

- n. 1 red flashing LED

- n. 1 resistor 1KOhm 1/4W

- n. 1 screw eyelet

- n. 1 spring OD 16mm x 13mm for clutch

- n. 2 M& nuts

- M3 screws, washers and nuts

- M8 threaded rod

- M8 nuts and washers

- M8 self-locking nuts

- PTFE tube 4mm

- pneumatic connectors 6mm threaded

- n. 1 Hall effect sensor

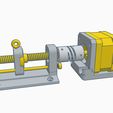

Filament guide V4

- n. 1 Nema17

- n. 1 T8 coupler

- n. 1 T8 screw 88mm

- n. 2 608Z ball bearing

- n. 1 3mm rod 69mm

- n. 1 T8 screw nut

- n. 1 10mm eyelet

- n. 1 M4x10mm screw

Credits

- Foreverwinter (https://www.thingiverse.com/thing:1241566) for its spool support

- Thomas Sanladerer (https://www.youmagine.com/designs/filament-diameter-sensor#information) whose filament diameter sensor is much much better than mine

Credits

- Foreverwinter (https://www.thingiverse.com/thing:1241566) for its spool support

- Thomas Sanladerer (https://www.youmagine.com/designs/filament-diameter-sensor#information) whose filament diameter sensor is much much better than mine

/https://fbi.cults3d.com/uploaders/15451373/illustration-file/627241ca-1802-44c0-a7aa-dbb570c91fcc/PHOTO_20191130_191108.jpg)